In order to keep ahead of the competition, many manufacturers are incorporating more complex machine tools into their manufacturing processes. These multi-function, multi-turret and multi-spindle machine tools mean less setup time and a higher level of machining accuracy, but also require more sophisticated programming to maximize productivity.

The right CAM system can handle this complex programming environment, assisting the programmer in creating verified G Code with optimum cycle time and zero collisions.

If you are considering a CAM system to improve your productivity, look for the following features:

- Accurate G Code certified by the machine tool manufacturer

- Full machine definition and simulation that includes all major moving parts of the machine

- Program synchronization and optimization between multiple spindles and turrets

- Integrated programming environment that can easily move back and forth between any milling cycle and any turning cycle

- A flexible and straightforward approach to 5-axis machining

- Customer support with expertise in YOUR machine tool brand

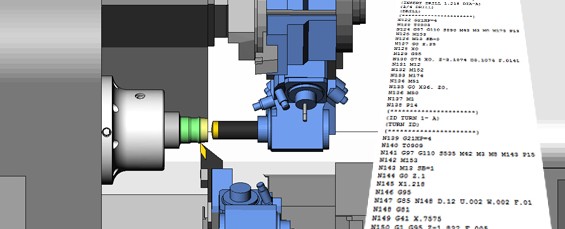

ESPRIT post processors are Okuma factory-certified, which means that programmers can be confident that Okuma machine tools will accurately execute the tool path. By developing relationships with machine tool builders, DP Technology, maker of ESPRIT, creates post processors that accurately mimic the kinematics of your machine tool (i.e. spindle, turret and tool movement). This virtual reality environment enables the programmer to detect any errors or collisions without costly scrap or damage to your machine.

Clear, straightforward commands to output code allow the user to program solid models and 2D geometry to depict the end result of a machined part and determine how to apply tool path intelligently. Because ESPRIT is capable of real-time, simultaneous simulation, the programmer can make informed decisions about two, three, and even four tools cutting simultaneously. Through the use of “sync” and “wait” codes, multiple axes can be programmed for optimum cycle time that is collision-free.

ESPRIT delivers a fresh, out-of-the-box approach to solving the issues that arise when programming complex multitasking machines, such as post processor development and virtual machine definition. In addition, its open-architecture Application Programming Interface (API) allows the user access to menus and toolbars from within a macro or add-in programming environment. This allows the macros and programs to adapt the ESPRIT interface to suit the individual needs of a particular application or business, further streamlining and automating the programming process.

With the complexity of programming these sophisticated machines, customer support is also essential. DP Technology, maker of ESPRIT, offers comprehensive, global support for their CAM products and engineering services. ESPRIT is able to work closely with the machine tool manufacturers, giving them the expertise to respond in a timely and accurate fashion. Application engineers who specialize in Okuma programming are available to assist with the programming of machines such as the MULTUS Series multitasking lathes, the LT-EX Series twin and three-turret lathes, and the Millac 33TU 5-axis machining center.

To learn more about ESPRIT’s membership with Partners in THINC, visit their page.