Tolland, CT – Mastercam X4 Lathe is here with a new suite of CAD/CAM tools focused on delivering speed and efficiency for your machining jobs. From roughing and finishing to easy grooving and threading, Mastercam Lathe has been designed to reduce programmer interaction and increase machining flexibility.

Powerful Part Modeling

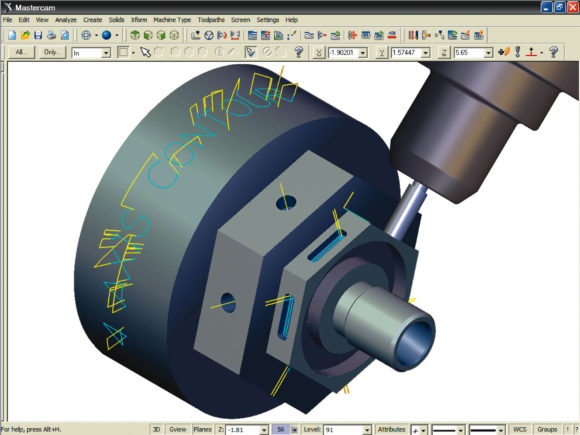

Mastercam’s streamlined CAD engine makes design work easier than ever before. Each piece of geometry you create is “live,” letting you quickly modify it until it’s exactly what you want.

Precise Turning

Mastercam X4 Lathe delivers a streamlined set of programming tools, including:

- “Quick Toolpaths” for programming parts with just a few clicks.

- Optimized facing including roughing and finishing.

- Complete threading with multiple starts, diameter calculation, and user customizable thread tables.

- In addition to turning, full 3- to 5-axis milling, including machines with B-axis tooling arms.

- Grooving with multiple depth cuts and pecking.

- Easily assign groove depth, width, wall angles, corner radius, chamfer, and corner dwells.

- Stock recognition for optimized turning toolpaths with minimal user interaction.

- Comprehensive lead-in/lead-out controls minimize the need to modify the CAD model to control tool motion.

- Steady rest option supports long work pieces, minimizing deflection from tool pressure and material weight

Designed for Ease

- Fully associative toolpaths are linked with your geometry. Modify any element of the job and immediately get updated toolpaths without starting over.

- Mastercam’s CAD File Change Recognition tracks files from Mastercam or any other CAD system and will show you what’s been changed for easy toolpath updating.

- Comprehensive insert libraries including Sandvik®, Kennametal®, Iscar®, and Valenite®.

- See your part as it will come off the machine with solid model toolpath verification.

For more information about Mastercam X4 Lathe, please visit www.mastercamlathe.com.