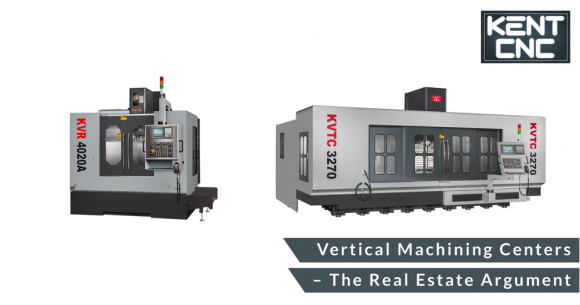

I’ve always been a fan of those little “phone booth” style vertical machining centers. They’re fast, the toolholders are small and light, and for the most part they boast enough axis travel to machine a wide variety of workpieces. Granted, they can’t take a massive cut, but they make up for at least some of that shortcoming with their quickness.

But for as long as shops have been buying CNC vertical machining centers, they’ve typically chosen ones with axis travels far greater than what’s needed for the parts they produce; if machine tools were houses, this would be the equivalent of buying a seven-bedroom house for a family of two. So what gives?

The bigger the machine, the more floor space it requires. More electricity is needed to power it, and it takes the operator more effort to reach deep inside when loading a new tool or swapping out a workpiece. Why not purchase one of those phone booths and give your back a break?

Yet it turns out there are some very good reasons to oversize your next machining center. For starters, jobs shops don’t know what’s coming through the door from one day to the next—an extra couple feet of X-axis travel beyond the bare minimum might be the difference between winning a killer job and a no-quote.

Provided the machine tool has the necessary spindle speed and power to effectively cut your parts, and isn’t so large that rapid traverse rates suffer, the additional real estate supports more vises and fixtures; this is turn means more parts, longer cycle times, and the opportunity to load up a few dozen parts and go do something productive while the machine is busy making chips.

Provided the machine tool has the necessary spindle speed and power to effectively cut your parts, and isn’t so large that rapid traverse rates suffer, the additional real estate supports more vises and fixtures; this is turn means more parts, longer cycle times, and the opportunity to load up a few dozen parts and go do something productive while the machine is busy making chips.

It also means greater flexibility. Even a 40-inch X-axis VMC has enough room for a handful of vises, a rotary table, and a tool probe off to the side. There’s plenty of space to have multiple jobs set up at once, and if your machine is equipped with quick-change workholding, swapping out a vise or two for the rush order your best customer just dropped takes about as long as it does to say “expedite fee.”

Taken one step further, a traveling column machine like the Kent CNC KVTC-2260/40 has sufficient elbow room that perhaps dozens of jobs can be set up at once, dropping setup time to virtually zero, or enough travel to machine a part the size of a coffee table. Phone booths have their place, but there’s nothing like having room to maneuver.