In 1988, if you had the idea to start a CNC machine tool company in Los Angeles, people probably would have said you were nuts.

I recently heard an interview with Steve Forbes, owner of Forbes Media LLC, in which he talked about what it takes to become a billionaire. He said if you have a great idea you don’t need to patent it, someone may steal the idea anyway. The person who makes the fortune is the one who takes an overlooked idea and runs with it like a fanatic.

He gave the example of when Steve Jobs visited the famed Xerox research lab in Menlo Park, California. Jobs saw a prototype of a hand-guided computer that Xerox had no use for. He Incorporated the idea into his new computer and called it a mouse. It put Apple on the map.

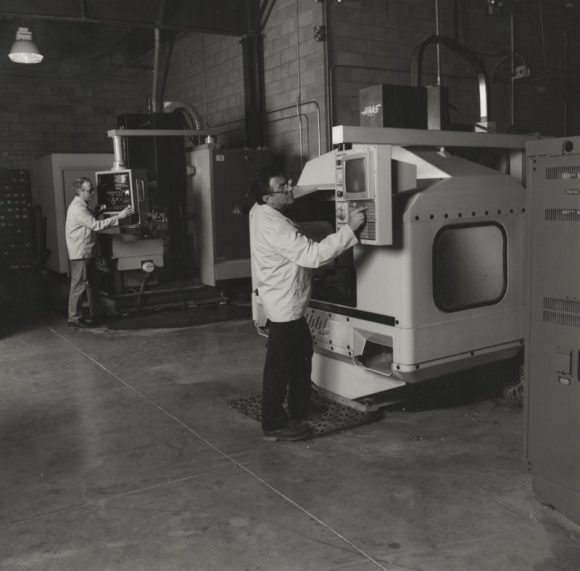

I thought of Gene Haas, now 71 years old, still leading Haas Automation, America’s largest Machine Tool builder. He has produced over 200,000 machine tools in the company he started 44 years ago in Los Angeles, which he later moved into a 1,100,000-square-foot plant, 60 miles north in Oxnard, California. Haas sales are well over $1 billion per year.

What did Gene Haas know that other American Machine Tool Builders like Warner & Swasey, Hardinge, Bridgeport, National Acme, and others had forgotten?

He knew what it was like to start a tiny job shop in LA. He knew that every dollar was precious and his competitors were smart. He knew what it was like to fight to hire employees and keep them. He understood that American manufacturing was on a decline and the survivors would look for value in machine tools that would be simple to run. The people who were making such machines were Japanese Builders like Mazak, Mori-Seiki and Okuma, and he copied their production methods.

He focused on price, service, and accountability.

Why did America’s old builders fold one by one? The classic story is about Burgmeister, which made drill and tap machines. In their final days, they sent out new machines with two-page lists of parts likely to fail soon after the machine was received.

Gene Haas didn’t see a shrinking machine tool business in the United States. He saw a massive opportunity to take the older builders’ place and eventually export his machines to countries like China that still appreciated American quality. Today, half of Haas’s revenue comes from its export business.

Gene Haas has shown that manufacturing in America is far from dead. But it has not been all triumph. Haas’s arch-competitor, Hurco, in Indianapolis, sued Haas and virtually every other CNC machine tool builder in the world for patent infringement in the late ‘90s. After a fierce battle, Hurco won multi-million dollar judgments against everybody except Haas, which refused to settle.

After several years in the courts, Hurco finally won its battle and Haas paid a significant penalty.

Today, Haas Automation continues to thrive.

Gene is a venerated figure in American manufacturing because he has shown that grit and listening to your customers can win them over. He has brought that passion to the racecar industry where his teams are heavily involved.

What I find most remarkable in Gene Haas’s career is his almost manic determination to keep the price down for his machining centers. His basic VF-1 CNC mill costs under $50,000, less than the price of the first machine he showed in the 1988 International Machine Tool Show.

Starbucks would never do something like that.

Nor could Davenport, today selling a new cam screw machine for $200,000. A similar one cost $25,000 in 1988.

Question: What’s the best thing about Haas Machines?

8 Comments

Gene Haas did a remarkable job in bringing competitive CNC machines to the market. The old line companies were devastated by the proliferation of Japanese CNC imports. This was primarily due to Japanese government policy which was directed by MITI (Ministry of Internation Trade & Industry) and the JMTBA (Japanese Machine Tool Builders Association). They specifically targeted the US machine tool market.

Was there mismanagement, lack of foresight, and lack of R&D that led to the downfall of the US machine tool industry? Certainly, those factors played a role, but for the whole segment to be gutted is unfathomable. The USA had no protections in place to protect the industry from foreign intrusion. I cannot believe that all of the companies such as NAMCO, B&S, W&S, Pratt & Whitney, Cincinnati-Milacron, Giddings & Lewis, Leblond, Sundstrand, Leblond, Fellows, Kingsbury, Kearney-Trecker, Bullard, Lamb, Gardner, etc. all succumbed to mismanagement within a short time frame. These companies were targeted and they were targeted well by the Japan machine tool industry with backing of the Japanese government. They were picked off one-by-one.

https://apps.dtic.mil/sti/tr/pdf/ADA257668.pdf

https://www.cia.gov/readingroom/docs/CIA-RDP84S00558R000100090002-3.pdf

https://www.usitc.gov/publications/332/pub1428.pdf

https://www.levyinstitute.org/pubs/wp/199.pdf

Haas started out using the Hardinge 5C index heads for his programmable indexers. As he got successful Hardinge refused to sell to him. He vowed to ‘put them out of business’ and basically has. They are barely still holding on at this point with mounting debt and unpaid bills.

Another great example is Cincinnati Milacron – they had the ethos that they built machines that were expensive, but would last forever. Haas built a machine that was cheap and wore out in 5 years. But those were productive 5 years and then you could buy another machine. Cincinnati Milacron went out of business building CNC machine tools – Haas is still with us!!!

Lodge and Shipley had the same issues in the end. Just ship ’em and fix ’em in the field. They had to get the machines out the door. Did it help? Absolutely not.

Llyod the turret drill maker was Burgmaster

Maybe you had a few too many Meister-Braus when you wrote the blog.

Thanks for the correction JC. Keep reading and smack me on the substance of the next time.

We have 31 Haas machines in our shop and they are great. We cut Inconel, stainless steel, steel and aluminum and the machines work great on all of them. It is easy to train new employees, many operators have experience on Haas machines from past employers or trade schools. The service is great and after using them for 10 years we can still sell them for a reasonable price. We will continue to buy Haas as we expand our business.

Haas… Price is right. Service is OK. Operators love them. What do you do?