Siemens, a global leader in technology for industrial automation hardware, digitalization

software and services, today announced its U.S. launch of MACHINUM at the International

Manufacturing Technology Show (IMTS).

MACHINUM is the CNC digitalization software portfolio designed to manage, analyze and

optimize shopfloor performance and aims to help machine tool users and builders improve

their operations and productivity through seamless software integration.

The digitalization portfolio is integrated into Siemens Xcelerator, allowing companies in the

machine tool sector to better facilitate digital transformation – making it more efficient, faster

and scalable in both manufacturing and design, and the demand for energy efficiency,

sustainability and high-quality product manufacturing. The technology is not limited to

SINUMERIK-controlled CNC machines, which allows the MACHINUM portfolio to be

integrated into any existing manufacturing environment to future-proof the shopfloor.

“It’s important for manufacturers to start or enhance their digitalization journey and

MACHINUM can help optimize industrial automation operations at any scale,” said

Dave Morley, mid-market sales manager, Siemens Digital Industries. “Siemens developed

a digitalization portfolio that drives increased usability and capability, and at a lower cost,

to provide greater access to this technology. Companies that can produce quality parts faster

and more efficiently will continue to outcompete competition — and integrating MACHINUM

can help do just that.”

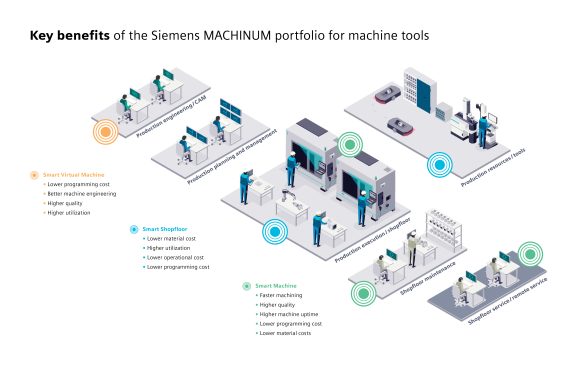

The MACHINUM portfolio is made up of three pillars: Smart Machine, Smart Shopfloor and

Smart Virtual Machine. Smart Machine offers lower programming and material costs, higher

quality machine uptime and overall faster machining by using machine data for real-time,

in-process quality control. Smart Shopfloor provides customers with lower material, operational

and programming costs, along with higher utilization, through more efficient preparation and

pre-production resource management. Smart Virtual Machine offers lower programming costs,

and higher quality and utilization for better machine engineering with the integration of digital

twin and closed-loop engineering.

Each pillar enhances performance, allowing users to increase speed, agility and endurance

of their operations. Within the Smart Virtual Machine pillar, companies can use digital twin to

enable dependable virtual machining processes, accelerating the run-in of new parts and

reducing costly downtime.

The MACHINUM portfolio features Adaptive Control and Monitoring (ACM) which allows users

to reduce their machining times by up to 15% and extend the life of their cutting tools, leading

to greater manufacturing productivity.

To see how MACHINUM can increase the speed, agility and endurance of manufacturing

operations, visit the Siemens booth 133249 during IMTS Sept. 9–14.

For more information about MACHINUM, visit: usa.siemens.com/machinum-pr