Charlotte, NC – (Oct. 2, 2024) Murata Machinery USA, Inc. (Muratec), a world-class automation leader in

fabrication machinery and automated turning centers, continues celebrating 50 years of automation innovation

in North America by marking a 35-year pioneering sheet metal fabrication milestone at FABTECH 2024.

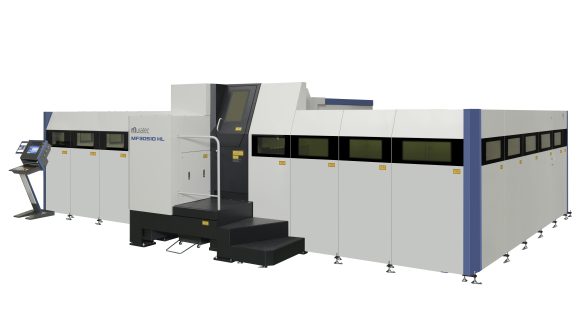

Muratec will highlight its rich legacy of fabrication ingenuity by showcasing the cutting-edge MF30510HL

combination punch press and fiber laser.

The MF30510HL, a multifunction machine that combines turret punch press and fiber laser processes, is

designed to meet the evolving needs of modern manufacturers. Developed in response to customer requests for

a machine to process larger sheet sizes than the popular MF3048HL, the MF30510HL features an expanded

work size of 5’ x 10’ (1219 × 2438 mm) and a punching capacity of 30 metric tons, offering unparalleled

versatility in processing larger material.

“We’re proud to showcase the MF30510HL at FABTECH 2024. This machine embodies our decades of

innovation, combining multiple sheet metal processes into one compact system to tackle the toughest challenges

manufacturers face today,” said Jeff Kalmbach, General Manager of Muratec USA’s Machine Tools Division.

“In today’s competitive market, speed alone isn’t enough—job shops need reliable flexibility to seize every

opportunity, and this multifunction powerhouse delivers. The MF30510HL is a true reflection of the

Muratec/Wiedemann legacy and our vision for the future of fabrication technology.”

A Century-long Legacy of Leadership in Sheet Metal Fabrication Innovation

Muratec’s legacy of leadership in sheet metal fabrication is rooted in the Wiedemann Machine Company, a

pioneer in the industry since 1916. Wiedemann revolutionized sheet metal processing after introducing the first

punch press in 1934 and the world’s first NC turret punch press in 1955.

In 1970, Murata Machinery Ltd. became an official partner of the Wiedemann division of the Warner & Swasey

Company, forming the Murata Warner Swasey Co. and strengthening its position in the industry. This

partnership deepened in 1989 when Murata acquired the Wiedemann brand, merging their expertise to create

Murata Wiedemann.

Murata Machinery Ltd., founded in 1935, established a permanent U.S. presence in 1974 with the founding of

Murata of America Inc. By 1991, the unified “Muratec” brand was launched. In 2002, Murata Wiedemann and

Murata of America were consolidated into Murata Machinery USA, Inc.

Today, Muratec continues to lead the industry with innovative fabrication technology, including turret punch

presses, combination punch presses with fiber lasers, and automation systems.

The MF30510HL streamlines operations by merging punching, laser cutting, forming, tapping, deburring, and

more into one cohesive machine. Its 4.0 kW fiber laser output enables the efficient processing of a wide range

of sheet materials and thicknesses. Integrating with Muratec’s automation systems, including the FG series

parts-sorting system, further enhances production efficiencies.

Key Features of the Muratec Combination Punch Laser (MF30510HL):

- Integrated Four-Station Rigid Tapping Unit: A four-station rigid tapping unit that enhances operational

versatility, efficiency, and high-speed tapping operations. - Vibration-Free Laser Operation: The fiber laser remains securely mounted on its dedicated frame,

eliminating potential vibration interference during cutting and punching operations. This deliberate

design ensures unparalleled precision and consistency in processing results. - Retractable Bottom Dies: This function retracts forming dies when not in use. This allows the machine

to perform laser cutting and punching operations to reduce the chance of scratching and catching while

making adjacent punch stations available. - Process Net Monitoring: Accelerates real-time monitoring and control for fiber laser operations and

provides operators and manufacturing managers valuable insights. Operators can make informed

decisions, optimize settings, and ensure optimal performance, productivity, and quality

To further enhance the MF series, we made the tooling styles of Wiedemann 114 and Thick Spring Style turrets

able to accommodate your present machine’s tooling inventory. This combination machine can also be

seamlessly paired with unmanned automation for loading and unloading, and with the FG series, Muratec’s

next-level parts sorting system to enhance production efficiency.

“The MF30510HL continues the Wiedemann legacy under the Muratec brand, advancing the innovation that

has driven our success,” said Kalmbach. “Combining laser cutting and punching in one machine offers

manufacturers unmatched flexibility. Integrating multiple operations and automation in a single system boosts

productivity and efficiency, ultimately delivering significant benefits to the bottom line.”

Visitors to FABTECH 2024 will experience the MF30510HL in action and explore Muratec’s full suite of

solutions designed to optimize manufacturing operations, solve labor challenges, and maximize shop floor

space.

Attendees are invited to visit booth S11073 to experience firsthand the precision and efficiency that have

defined Muratec’s legacy.

To learn more about this metal forming powerhouse, visit https://www.muratec-usa.com/products/606/