Do your buyers view your machined components as interchangeable with other components? And, if they do, can you blame them? After all, when every shop claims tight tolerances, on-time delivery, and ISO certification, how can any of them, including your shop, escape the commodity trap and truly stand out?

Commoditization happens in precision machining when your buyers treat your service like a line item in a catalog rather than as a valuable partnership. The result? A relentless race to the bottom on price. Brand loyalty erodes. Margins shrink. Your expertise becomes invisible.

To make matters worse, many shops rely on SEO as their primary differentiator. But with search engines saturated with similar messaging, it’s nearly impossible to rise above the noise without a compelling, differentiated voice. When every shop boasts “high-quality CNC machining,” “fast turnaround,” and “competitive pricing,” everyone sounds like they are selling a commodity.

How Precision Machined Parts Get Treated Like Commodities

When buyers perceive a product as a commodity, that product suffers from a cluster of marketing and sales challenges that reinforce each other. First, by definition, there’s little perceived differentiation. After all, when buyers assume that your manifold is no different from the one made by the shop down the street, that (mistaken) assumption makes price the only battleground. Without a clear value proposition, buyers default to the lowest quote, treating your work like a line item on a spec sheet rather than as a solution.

This dynamic also erodes brand loyalty. If your shop isn’t offering visible value beyond form and finish, customers have no reason to stay. And so they don’t. They switch suppliers to save a few cents. And compounding the problem is the sheer volume of online competition. With every shop claiming to be “high-quality,” “on-time,” and “cost-effective,” buyers become numb to the messaging. You end up lost in a sea of sameness, struggling to stand out.

And, unfortunately, many high-quality parts are frequently lumped into the commodity category, regardless of the expertise required to produce them. Here are some precision machined parts that many buyers treat like commodities:

- Valve bodies and components

Including stems, guides, and bonnets, these parts are often purchased based on spec and price, even though their performance can dramatically impact flow control systems. - Heat sink bases and electronic housings

Often machined from aluminum or copper, these parts are key to thermal management in electronics, yet they’re typically viewed as interchangeable. - Manifolds (standardized or simple)

Whether for fluids or gases, CNC-machined manifolds are often selected from a catalog rather than assessed for custom improvements. - Flanges and mounting plates

Machined to standard bolt patterns or dimensions, these parts rarely get credit for the precision or process improvements required to meet exacting tolerances.

Each of these components plays a critical role in the systems they serve. Yet buyers all too often reduce them to commodities. That’s a lost opportunity. For them and for you.

Why Thought Leadership Works

Thought leadership helps machining shops escape this trap by reframing how buyers perceive the value of machined parts, components and assemblies. Instead of focusing on part specs and pricing, thought leadership shines a light on your expertise, problem-solving ability and real-world application knowledge. It transforms you from a vendor into a trusted guide.

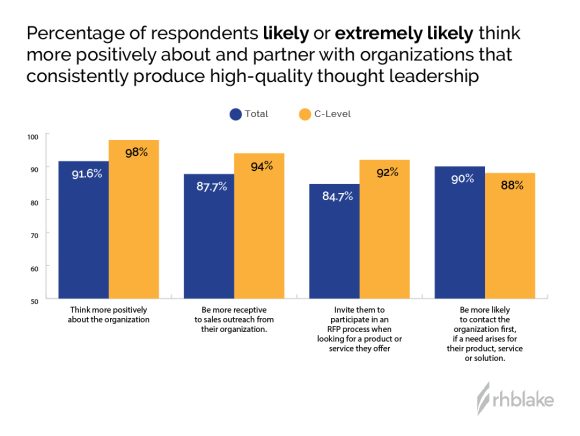

And this isn’t just a marketing theory. In our 2025 Thought Leadership in Manufacturing Report, we reveal that 88% of B2B decision-makers in the manufacturing ecosystem say they are more likely to consider a company that positions itself as a thought leader. Why? Because thought leaders build trust, demonstrate authority and educate rather than sell. In a crowded industry, the shop that teaches, wins.

But how, you may be wondering, can you turn your manifolds, flanges, housings and other precision-machined products into stories that spark interest, build trust and win business? By shifting the conversation from features to insights. Here’s how.

Focus on Real-World Applications

Instead of leading with material specs and tolerances, show how your parts perform in specific use cases. For example, a whitepaper titled, “Designing Valve Bodies for Corrosive Environments in Offshore Oil Applications” demonstrates your understanding of environmental stressors and long-term performance, not just machining capability.

Solve Today’s Problems

What operational headaches do your customers face? Use your thought leadership content to address those directly. If you write a blog post called “Why Tolerance Stack-Up Leads to Expensive Rework, and How to Prevent It,” you position your shop as a solutions provider, a problem-solver, and not just as another commodity fabricator.

Demonstrate Expertise

And while we are on the subject of expertise, don’t simply say you’re an expert. Prove your expertise by publishing insights on trends, best practices and emerging technologies in your space. If you attend a trade show, for instance, and deliver a keynote talk called

“Six Reasons Powder Metallurgy Will Disrupt Traditional CNC for Small Electronic Housings,” show attendees (some of whom are potential customers), will see that you deliver timely, thought-provoking information that shows you’re staying ahead of the curve.

Answer Buyer Questions

Your sales team and engineers field questions every day. Turn those into educational content that drives search traffic and sales conversations. If, for example, buyers are forever asking your team how to choose the right alloy for thermal conductivity and machinability, go ahead and answer that common pain point in a blog post titled, “How to Choose the Right Alloy for Thermal Conductivity and Machinability.” You’ll attract qualified prospects looking for guidance.

Tie Everything to Business Value

Executives and procurement managers alike want to know one primary thing: how does product help our business? They want to know how your products affect their bottom line and competitiveness. This means a primary goal of your thought leadership is to tie everything you publish to business value—the business value of your buyers, that is.

For example, publishing a case study titled “Switching to Precision-Machined Aluminum Manifolds Saved Our Client 14% on Assembly Time” translates your capabilities into measurable outcomes. This re-positions you in the minds of some buyers as a partner who delivers business value as opposed to a shop that fabricates stuff.

Tailor Content to Buyer Roles

Different stakeholders care about different things. Match your thought leadership to their mindset.

- Operational buyers want detailed how-to advice and process recommendations.

Example: “4 Ways to Prevent Galling in Stainless Valve Stems” - Engineering teams want technical depth.

Example: “Machining Techniques that Improve Heat Sink Efficiency” - Executives want strategy and ROI.

Example: “How Strategic Supplier Relationships Reduce Lifecycle Costs”

This multi-layered approach builds credibility with every persona in the buying cycle, whether they are technical, tactical, or strategic. And that leads to results. As we reveal in our report, 75.7% of B2B manufacturers are more willing to pay a premium to work with organizations or individuals that produce thought leadership, highlighting its value as a differentiator in competitive markets.

Escape the Commodity Catch

When buyers see your products as indistinguishable from everyone else’s, you’re stuck competing on price. And that’s a losing proposition for most precision machining shops. But here’s the good news: Commodity buyers care about price only until they understand value. And thought leadership is how you show them that value.

By positioning your team as experts, educators and problem-solvers, you stop being just another machining service. You become a trusted partner, someone who understands your customer’s challenges and offers more than just a part. In a world of specs and quotes, the machining companies that teach will always outperform the ones that pitch.

About the author

Dan Konstantinovsky is Strategy Director at RH Blake, a leading manufacturing marketing agency based out of Cleveland, OH.