“Walnuts are cool,” Shawn Wentzel says with a shrug when asked why he decided to plant 7,000 walnut trees on his property in Lodi, California. Now two years old, the orchard is a growing side business. Surrounded by rolling plains and vineyards, it begins at the back door of his primary source of income: an old horse-barn-turned-machine-shop with plenty of space for additional milling and turning equipment to complement the current stable of six machine tools.

He named the shop Wenteq, and with revenue growing at approximately 10 percent per year, prospects for filling the rest of the 15,000-square-foot space seem bright. The newest technology addition is a robot to load and unload various parts for automotive and agricultural equipment from a turning center. With Mr. Wentzel opting to do much of the legwork, integrating the robot is a work in progress. No matter. As was the case with the walnut trees, he sees no barrier in his lack of automation-integration experience. “There’s nothing like doing it yourself,” the 36-year-old says, articulating the independent spirit that first led him to turn his machining hobby into a business nearly 15 years ago. “What can anyone learn in school that they can’t learn on the shop floor?”

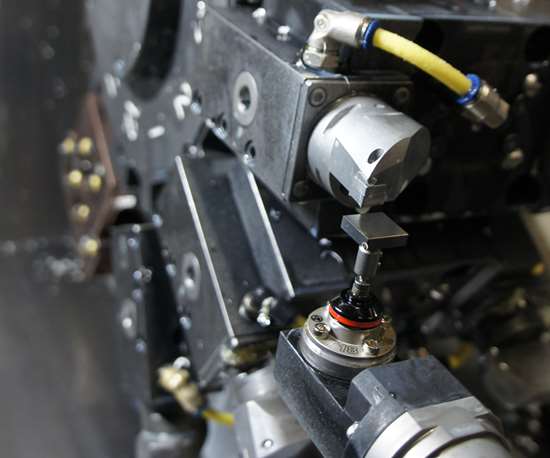

Whether purchased online or made to order, custom control functions help a contract machining startup save time and avoid mistakes. Find out which apps are simplifying Wentzel’s shopfloor in the article on Modern Machine Shop, by Matt Danford.