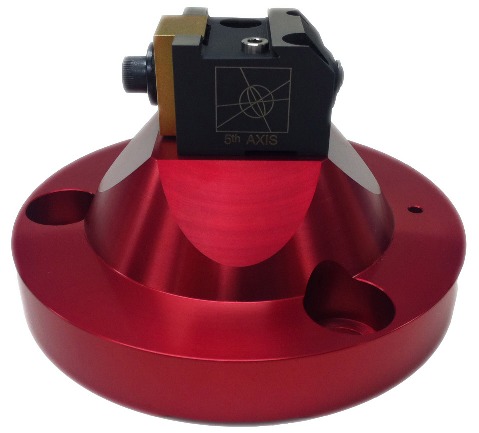

Designed for precision and efficiency, 5th Axis’s line of dovetail fixtures are compatible with all 3, 4, and 5 axis CNC machines. With a simple stock prep operation, 5th Axis Fixtures hold onto as little as .06 (1.52 mm) stock, far less than a traditional vise. For 5 axis machining, 5th Axis Fixtures’ simple and robust design allows the cutter to easily reach all five faces of the work piece, eliminating additional setups with little second operation cleanup. On 3 axis machines, 5th Axis fixtures’ modular design and small footprint enable multi-part gang fixturing, allowing users to get the most out of their machines at a fraction of the price of vise mounted systems. The 5th Axis Fixtures dovetail system also incorporates a precision locating system so that parts can be roughed on lower cost machines and relocated for finishing, speeding shop through-put. Precision locating pin repeats within .001 (.025mm). The entire line was built with flexibility and durability in mind; they can be mounted in nearly any configuration imaginable. They use standard, replaceable hardware and are built from 4130 hardened steel to exacting standards.

Utilize all your 5-Axes.

Work holding is a difficult obstacle to overcome in the world of multiaxis machining. With high spindle speeds, rapid movements, and a need to reach all five faces of the work piece, machines shops are looking for new ways to hold parts. 5th Axis Fixtures was launched to provide a line of simple and robust dovetail 3, 4 and 5 axis CNC machining fixtures that address all of those needs. 5th Axis Fixtures was created out of necessity by leading 5-axis CNC machine shop, 5th Axis Inc. After years of producing our own custom workholding fixtures we decided to make them available to the public. Designed by machinists for machinists, we manufacture high-quality and affordable 5 axis workholding fixtures that outperform traditional CNC workholding vises.

With a simple stock prep operation, 5th Axis Fixtures hold onto as little as .05” stock, far less than a traditional vise system. The dovetail clamp wedges the stock down ensuring a positive secure hold on much less stock than a vise. Use of dovetail work holding fixtures for 5-axis CNC machining allow for smoother running and more reliable jobs. The 5th Axis Fixtures dovetail system also incorporates a precision locating system so that parts can be roughed on lower cost machines and relocated for finishing, speeding shop through-put. The precision locating pin repeats within .001”, so parts can be taken in and out of the fixtures without a worry that parts may be relocated in the wrong position.

The problem that most machine shops run into while using a vise on their 4 and 5 axis machine, is that you have to hold onto a large amount of material and you can not reach all surfaces of the work piece. 5th Axis Fixtures allow the cutter to easily reach all five faces of the work piece. This speeds up production and allows the machine to run with little to no stoppage time. Operation times can be cut by as much as 40% with these dovetail fixtures and set up times are nearly eliminated.

The fixtures feature a modular design with endless mounting possibilities. We understand that each machine shop has unique needs in terms of mounting and utilization of fixtures. The D-series can be mounted on all 3, 4, and 5 axis CNC machines and robotic loading systems. Mount them however you like: on pallets, tooling plates, pedestals, tombstones, pyramids, side by side, or simply by themselves, the decision is yours to make. Five models are currently available in sizes: ½ x ½”, 1 x 1 ½”, 2 x 2”, 3 x 6”, and 3 x 10” to accommodate stock of all sizes. A misconception about dovetail fixtures is that they are only suitable for smaller parts. We have proven that they are capable of holding parts as small as .5” up to 24” and larger. We do not put a limit on the size of the part our fixtures can hold, you are more limited by the rigidity of the part you are machining than overall size. Unlike many other products on the market, our fixtures are built from hardened 4130 steel to exacting standards. The locating pin, dowel pins, and threaded insert are all removable and replaceable.

In addition to the modular design and replaceable components, part density was major factor in the creation of these dovetail fixtures. “We specialize in high production machining and manufacturing, and we needed a way to make as many parts in the shortest possible time. Our dovetail fixtures allow us to load our stock onto our fixtures, hit cycle start, and let our machine do the work for us” Says CEO Chris Taylor. 5th Axis dovetail fixtures allow machine shops to run lights out without a worry of throwing a part. The PY6420D1151S, exemplifies part density, it allows four parts to be fully machined simultaneously on one Erowa 148mm pallet. 5th Axis dovetail fixtures allow machine shops to fill up their pallet systems without breaking their banks. These dovetail fixtures have more capabilities than a traditional vise at half the price.

Shop owners are often hesitant to utilize the capabilities of a dovetail system because of the addition of the stock prep operation. Carbide end mills are expensive and must be replaced often when prepping dovetail stock. That is why we have created a custom dovetail cutter. The DC2253VBMT dovetail cutter is built from H13 tool steel with standard, replaceable v-type inserts. It features Ø 1” H6 for set screw, collet or shrink fit holders. The dovetail cutter completes the dovetail system, and allows for cost effectiveness and accuracy shop owners need in today’s machining environment.