CoreTechnologie’s 3D_Evolution analysis software accurately identifies collisions between components and helps to avoid costly changes and delays for machinery and plant engineering. The latest version of the integrated DMU Inspector tool has an optimized web interface and enables fast analysis of large 3D CAD data as well as efficient collaboration between development teams.

German French software manufacturer CoreTechnologie (CT) has launched a new software version of the 3D_Evolution DMU Inspector for collision checking. The software was developed specifically for the needs of mechanical and plant engineering. The new tool makes it possible to ensure that there are no collisions before assembly, and indicates all penetrations between components. This reliably prevents expensive modifications and delays during the assembly of the machines. Particularly when assembling complex machines abroad, faulty and not fitting parts and the resulting changes will result in high costs and delays that can be effectively avoided with the DMU Inspector.

Precise Collision Checking

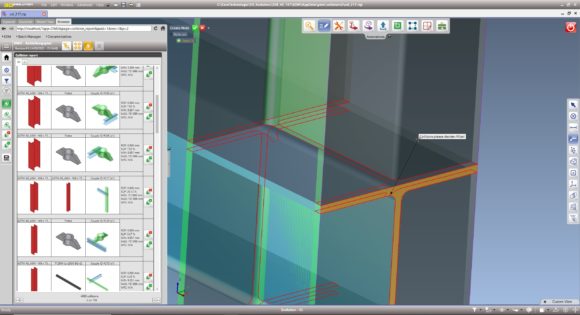

Especially for mechanical and plant engineering, the distinction between contacts and an actual collision is crucial for a successful collision analysis. Inaccurate, tesselated models used by other tools often display thousands of non-existent collisions, making a reasonable collision detection impossible. To address this challenge, DMU Inspector was developed as the world’s first tool to generate collision analysis on the exact CAD models rather than on a triangulated approximation. This allows precise differentiation between contact and penetration to display only real collisions.

High Performance and Ease of Use

For collision detection of large amounts of data, the multiprocessor calculation of the DMU Inspector software offers enormous performance advantages. The software, which can be installed as a webservice, enables calculation on any number of processors. The documentation of the results and the collaboration of the development teams of the data centrally hosted on a server thus becomes more efficient. Designers log into a project, view the collisions in a web browser and perform a detailed analysis in the integrated 3D viewer. In contrast to static reports, for example in PDF format, the project progress is documented dynamically in the DMU Inspector. When the assemblies are recalculated, only the modified and corrected components as well as directly adjacent components are re-examined for collisions.

The tool is enables a very fast display of large data, simple operation as well as clear representation of the analysis results. Collisions between components or subassemblies are displayed in a list of the web browser and details of the collision can be viewed in the 3D Viewer. Clever filter and project management functions support the successful cross-team collaboration.

The DMU Inspector supports all common CAD formats such as Catia, Nx, Creo, as well as STEP, JT, PLMXML, Solidworks and Inventor assemblies. Due to the independent database and the numerous interface formats, the software is flexible and immediately ready for use in any PLM environment without a complex integration.

Further information is available at www.coretechnologie.com/products/3d-evolution

Background Information

The software manufacturer CoreTechnologie, with locations in Germany, France, the USA, Japan and Great Britain, has been led by the managing directors Dominique Arnault and Armin Brüning since its foundation in 1998. With innovative products, the visionary company has consistently optimised its product portfolio and secured technological leadership in the field of conversion software. Every year, CoreTechnologie invests more than 30 percent of its turnover in researching and implementing new technologies and today has the complete product range in this field.

The focus of technology development is the 3D_Evolution product line, which ensures efficient and loss-free exchange of complex data structures between independent and heterogeneous CAX software solutions. With enormously powerful native interfaces for all leading CAD systems and for conversion into all common 3D formats, the software module ensures optimal interoperability of the most diverse IT solutions.

In addition to providing visualisation and manufacturing data across different systems, CoreTechnologie offers outstanding technologies for automatic data correction, feature-based conversion, geometry optimisation, quality control and long-term archiving, as well as for visualising complex 3D models. Software components for software manufacturers of the most diverse CAX applications are the second main pillar of the company.

CoreTechnologie’s customer portfolio includes more than 600 companies from the automotive, aerospace, mechanical engineering and consumer goods industries, many of them quality leaders in their respective segments.