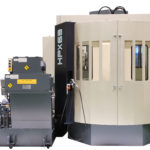

[FRANKLIN LAKES, NJ – NOVEMBER 2009] Mitsui Seiki recently published a new 12-page brochure detailing its recently introduced “HPX-63” 4-axis CNC Horizontal Machining Center. Some of the key design criteria included in this machine include a large work size capacity featuring a swing diameter up to 1050mm and a work height (Y-axis) up to 1050mm. Axis stroke is 1000mm in X-axis and 900mm in Z-axis. The pallet size is 630mm. The B-axis rotary table offers 12 rpm and high torque, high acceleration properties. The rapid travel rates are 32m/min with 0.5G acceleration/deceleration. The cutting feed rate is 12m/min.

This machine, as with all Mitsui Seiki machining centers, is made for precision work. Its castings are metallurgically configured for the utmost stiffness, its box way axis slides are hardened, ground, and hand scraped. All assembly surfaces are hand scraped and fitted. The assembly is then meticulously inspected to ensure both geometric and positioning accuracy. Positioning accuracy and repeatability is 0.001mm.

The ruggedness, rigidity, and precision of the HPX-63 make it ideal for the aerospace, energy, compressor, mold and die, fixtures and tooling, automotive prototyping, and general precision machining industries. Titanium, Inconnel, tool steel, stainless steels, and aluminum are among the materials the HPX-63 can cut effectively. The spindle, Mitsui’s own, automatically compensates for thermal changes and does not require a “warm up” period. The company offers several spindle options to meet user needs for direct or gear drives and the amount of torque and rpm requirements. Mitsui Seiki also has a choice of coolant and filtration options.

For more information, or to request a brochure, contact Mitsui Seiki, 563 Commerce Street, Franklin, NJ, (201) 337-1300, www.mitsuiseiki.com.