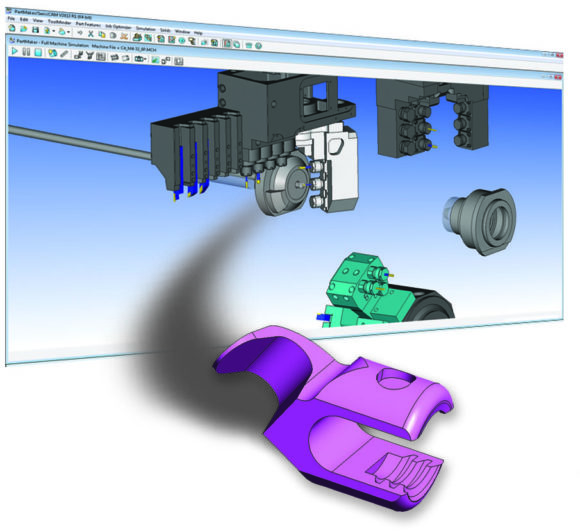

Fort Washington, PA – PartMaker Inc., a division of Delcam Plc, will unveil its latest version of PartMaker Software for programming CNC Mills, Lathes, WireEDM, Turn-Mill Centers and Swiss-type lathes at IMTS 2012 in Chicago, IL. Among a number of other enhancements, this new version will feature a totally revamped surface machining module offering PartMaker users some of the most powerful CAM machining algorithms on the market today for 3, 4 and 5 axis simultaneous milling operations on a variety of machining platforms including CNC Mills, Turn-Mill Centers, Bar-Fed Mills and Swiss-type lathes.

PartMaker will be exhibited in the booth of its parent company, Delcam Plc, at IMTS 2012. PartMaker will be demonstrated along side Delcam’s other leading edge manufacturing software products including the PowerMILL, PowerSHAPE, FeatureCAM, ArtCAM and PowerInspect range. The Delcam booth will be the largest CAM booth at IMTS 2012, where the most comprehensive range of CAM products at the show will be on display.

PartMaker’s has pioneered the field of CAM software for multi-axis Turn-Mill Centers and Swiss-type lathes. The software has a vast array of robust post processors and machine simulation files for virtually every machine model ever built from such leading builders as Citizen, Mazak, Star, Mori-Seiki, Tsugami, Okuma, Tornos, Doosan, Hanwha, Nakamura and many, many others. PartMaker’s technology for automating the programming of multi-axis Turn-Mill Centers and Swiss-type lathes is protected by two U.S. patents.

“PartMaker Version 2013 proves that power and ease of use don’t have to be trade-offs users have to make with their CAM system,” says PartMaker Inc. division President Hanan Fishman. “With a host of new, advanced milling strategies, PartMaker Version 2013 offers its users perhaps the most comprehensive and powerful CAM system on the market today for the full spectrum of production machining applications, all while maintaining the software’s hallmark, industry-leading ease of use.”

“PartMaker’s new Advanced Surface Machining (ASM) functionality is based on the same technology and algorithms underpinning Delcam’s PowerMILL, the leading CAM system on the market for the manufacture of complex shapes,” says Fishman. “The new functionality being offered in PartMaker’s ASM answers the needs of our customers making ever increasingly more complicated parts, particularly for those in the medical device and aerospace arena. Also, machine tools are becoming more complex, with 5-axis simultaneous milling now even becoming available on a number of Swiss-type lathes.”

Introducing the Advanced Surface Machining (ASM) Module

The new high-end milling functionality available in PartMaker Version 2013 will be known as the Advanced Surface Machining module, or ASM for short. ASM will replace PartMaker’s Surface Machining Wizard (SMW) module for three, four and five axis machining. For existing PartMaker users, the upgrade to ASM will be provided free of cost and the transition will be very easy to make.

The benefits of the ASM module for PartMaker users are numerous. The will allow for faster tool path calculation, greater tool control and improved surface finishes, among other benefits.

The ASM module will feature a wide variety of high-end milling strategies that can be applied across the entire suite of PartMaker CAM applications including PartMaker Mill, PartMaker Turn-Mill and PartMaker SwissCAM. The powerful surface machining strategies in ASM are the same as those found in PowerMILL, Delcam’s industry leading CAM system for the manufacture of complex shapes. Each strategy provides for full tool control enabling them to be used in either traditional 3-axis methods or up to 5-axis simultaneous machining methods, depending on a machine tool’s capability.

The advent of ASM extends PartMaker’s 5-axis simultaneous milling functionality to CNC milling centers, making PartMaker an unsurpassed solution for production oriented manufacturers to solve all of their CNC programming challenges, Milling, Turning, Wire EDM, Turn-Mill and Swiss with one, unified programming platform.

Vortex Technology for High Speed Machining

PartMaker 2013 will feature Delcam’s new Vortex High Speed Machining Strategies (as part of ASM). The Vortex area-clearance strategy, for which Delcam has a patent pending, has been developed by Delcam specifically to gain the maximum benefit from solid carbide tooling, in particular those designs that can give deeper cuts by using the full flute length as the cutting surface. It can be used for 2.5 and 3-axis roughing, 3+2-axis area clearance and for rest machining.

Like other Delcam roughing strategies, Vortex toolpaths are calculated to give more efficient machining by following the shape of the part and by keeping air moves to a minimum. This is particularly important for rest machining operations. One fundamental problem with conventional area-clearance strategies is that the optimum cutting conditions only occur during a straight-line cut. Any internal corners within the model significantly increase the engagement angle of the cutter. To protect the cutter, this increase needs to be balanced by setting a lower feed rate. The user then has the choice of using this lower rate over the whole toolpath, which increases the machining time, or varying the feeds and speeds as the cutter moves around the model and so increasing wear on the cutter.

Unlike other high-speed roughing techniques that aim to maintain a constant theoretical metal-removal rate, the Vortex strategy produces toolpaths with a controlled engagement angle for the complete operation. This maintains the optimum cutting conditions for the entire toolpath that would normally be possible only for the straight-line moves. As a result, the cutting time will be shorter, while cutting will be undertaken at a more consistent volume-removal rate and feed rate, so protecting the machine.

Because Vortex toolpaths have a controlled engagement angle, tools will never be overloaded and so will achieve the maximum tool life. Shock loading caused by changes in the contact angle is minimized, preventing chipping of the flutes. In addition, the stability of the cutting conditions gives more consistent edge temperatures, so prolonging the life of the tool coating and removing heat damage to the surface of the part. Finally, the ability to use stepdowns of up to two, or even three times, the tool diameter spreads the tool wear evenly over the cutting surface of the tool, again contributing to longer tool life.