New release of PartMaker’s industry leading 3D CAD for CAM application now shipping to end users.

Fort Washington, PA – PartMaker Inc., a division of Autodesk’s Delcam unit, has released PartMaker Modeling 2014. PartMaker Modeling is PartMaker’s 3D CAD for CAM application which provides users the ability to create 3D solid models from scratch as well as repair and modify 3D engineering data of any origin. PartMaker Modeling is the most powerful 3D CAD system available alongside a production-oriented CAM product on the market today. PartMaker Modeling 2014 features a host of new exciting enhancements from the previously released version, including the utterly unique Radial Cut Wizard for creating cylindrically wrapped part features as well as improved direct modeling and feature recognition functionality. PartMaker Modeling 2014 is a particularly focused release for users that make parts on Turn-Mill Centers and Swiss-type lathes as it includes a wide variety of functionality for creating milled features on parts that are cylindrical in nature.

PartMaker Modeling 2014 includes the unique Radial Cut Wizard. This new feature allows for very quick and intuitive creation of solid cut features on cylindrical surfaces. This functionality is particularly helpful for creating “wrapped” features on cylinders that typically require cylindrical interpolation programming when machined.

Additionally, PartMaker Modeling 2014 includes automated functionality for snapping both geometry and solid features to existing faces. This makes creating both milled and drilled features such as hexes, flats and holes of any orientation much faster than previous versions.

PartMaker Modeling 2014 includes a number of enhancements to the software’s direct modeling functionality for altering “dumb” solid models, or 3D models with no feature history created in other solid modeling systems. One particularly helpful new direct modeling feature is the Merge Faces command. This allows a number of coincident but separate faces to be merged into a single face automatically which makes altering or removing features attached to these faces much faster and more automated.

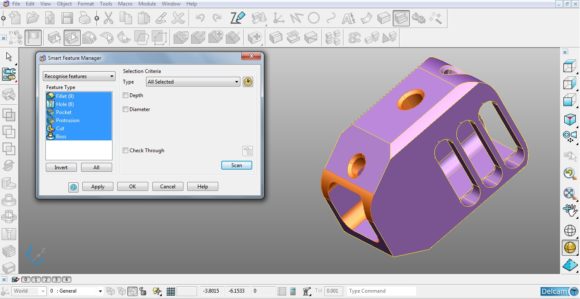

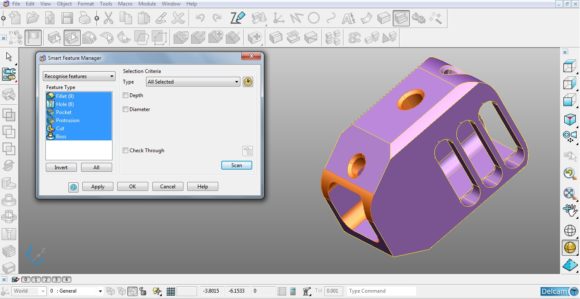

PartMaker Modeling 2014 also has significantly improved functionality for extruding multiple regions with hollow shapes automatically. The software’s feature recognition functionality has also been hugely improved and further automated through the addition of the Smart Feature Manager which allows solid features to be extracted automatically from dumb solids. Using the Smart Feature Manager, you can also control and filter which feature sets, such as just holes, are extracted from a dumb model.

”PartMaker Modeling 2014 is another great step forward in providing part manufactures a solid modeling tool that really meets their needs for a powerful yet easy to use full-featured 3D modeling system,” says PartMaker Inc. division President Hanan Fishman. “PartMaker Modeling 2014 really gives precision part manufacturers more of what they need to be more productive without cluttering their work flow with tools that are of no use to them.”

More on PartMaker

PartMaker is a Knowledge Based Machining system, allowing it to provide a substantial gain in programming efficiency by remembering the tools, material and process information necessary to machine individual part features. It thus relieves the user from reentering the same features information for subsequent parts. It also improves productivity by placing the emphasis on tool management functions.

PartMaker pioneered the field of CAM software for Turn-Mills and Swiss-type lathes with its patented Visual Programming Approach for programming multi-axis lathes with live tooling. It assures quicker learning and easier use. It makes an extensive use of pictures to help the user describe tools, part features and machining data. Synchronization of tools working on multiple spindles is achieved by a few mouse clicks.

PartMaker Inc. is a subsidiary of Delcam, the world’s leading developer and supplier of complete CAD/CAM software solutions. Delcam is a division of Autodesk. Autodesk helps people imagine, design and create a better world. Everyone–from design professionals, engineers and architects to digital artists, students and hobbyists–uses Autodesk software to unlock their creativity and solve important challenges. In North America PartMaker is sold directly by PartMaker Inc. PartMaker is sold overseas through a network of sales partner offices operating in over 120 countries.