Delcam to demonstrate PartMaker’s novel solutions for B-axis equipped Turn-Mill Centers and Swiss-type lathes at the West Coast’s premier manufacturing event.

Fort Washington, PA – PartMaker Inc., a division of Delcam, will demonstrate the latest version of PartMaker Software for programming CNC Mills, Lathes, WireEDMs, Turn-Mill Centers and Swiss-type lathes at Westec 2015 in Los Angeles, CA, September 15 – 17, 2015. Highlighting the new version are a variety of improvements in the software to support today’s latest breed of B-axis equipped Turn-Mill Centers and Swiss-type lathes. B-Axis refers to the ability of a multi-axis lathe to perform milling on at any angle, not just in a vertical or horizontal position.

Other highlights of PartMaker Version 2015 include the ability to generate a Post Processor Reference Guide, an on command manual explaining how to program a given multi-axis lathe and take advantage of all the machine’s capabilities with PartMaker as well as more powerful milling and turning functionality and improvements in the software’s knowledge based technology for storing optimal feeds and speeds for additional tools.

“B-Axis functionality, once at the bleeding edge of multi-tasking, has become more common place on both Turn-Mill and Swiss applications,” says PartMaker Inc. division President Hanan Fishman. “PartMaker was an early entrant into the market for CAD/CAM support of such functionality and has established both thought and technological leadership for programming B-axis enabled machine tools.”

“In PartMaker Version 2015, we’ve made the software functionality for supporting B-axis machines both easier to use and more powerful,” says Fishman. “For a technologically advanced market like the West Coast with its heavy emphasis on both aerospace and medical device machining, we see these developments as particularly helpful to keep both current and future PartMaker users more productive.”

PartMaker 2015 also includes specialist support for a new breed of machine tools that has been growing steadily in popularity in recent years called Vertical Mill-Turns (VMT). These machine tools are unique because they provide the turning functionality typically found on a VTL (Vertical Turret Lathe) with that of a 5-axis VMC (Vertical Machining Center).

More on PartMaker

PartMaker is a Knowledge Based Machining system, allowing it to provide a substantial gain in programming efficiency by remembering the tools, material and process information necessary to machine individual part features. It thus relieves the user from reentering the same features information for subsequent parts. It also improves productivity by placing the emphasis on tool management functions.

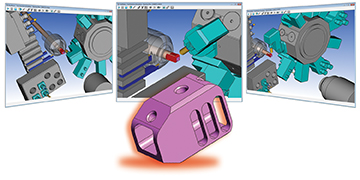

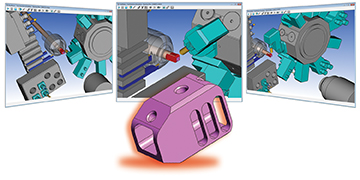

PartMaker pioneered the field of CAM software for Turn-Mills and Swiss-type lathes with its patented Visual Programming Approach for programming multi-axis lathes with live tooling. It assures quicker learning and easier use. It makes an extensive use of pictures to help the user describe tools, part features and machining data. Synchronization of tools working on multiple spindles is achieved by a few mouse clicks.

PartMaker Inc. is a subsidiary of Delcam, the world’s leading developer and supplier of complete CAD/CAM software solutions. Delcam is a wholly-owned, independently-operated subsidiary of Autodesk. Autodesk helps people imagine, design and create a better world. Everyone – from design professionals, engineers and architects to digital artists, students and hobbyists — can use Autodesk software to unlock their creativity and solve important challenges. In North America PartMaker is sold directly by PartMaker Inc. PartMaker is sold overseas through a network of sales partner offices operating in over 120 countries.