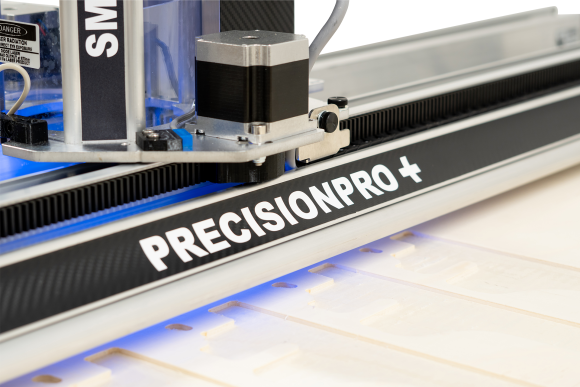

Yeti Tool have today launched SmartBench PrecisionPro +, the world’s first CNC router with automated feeds and cutting speeds for its customers.

Having recently unveiled SmartBench Mini, a smaller version of their industry-disrupting portable large-format CNC router, the British manufacturing firm has now brought the first ever machine of its kind onto the global market.

“We are so proud of the team in making this a reality” said Ed Sells, Technical Director at Yeti Tool.

“We aren’t a big company but we have the skills in-house to produce a world first for the CNC sector.”

Many Smartbench customers are new to CNC, and in the past some have learnt about manual feeds and speeds on their routers through trial and error.

The PrecisionPro+ has been developed to combat this.

By having automated feeds and speeds built into the router, this reduces the risk of human error from CNC projects, completes cutting more efficiently, and reduces the amount of material wasted on projects.

“The PrecisionPro+ listens to the spindle throughout the whole cut and is self-monitoring, so CNC projects are quickly and fully optimised as a result” commented Ed.

“The router changes its own feed rates during cutting, which means that new and experienced CNC users alike can complete projects more confidently and productively in future.”

Customers who have purchased a SmartBench V1.3 can add on this new hardware to their existing machine. It is also available for SmartBench Mini routers.

“Yeti Tool are the Tesla of the CNC sector. PrecisionPro+ represents the next level of automation in CNC.” concluded Ed.

To find out more about SmartBench in your region, country or territory, please visit https://www.yetitool.com/ABOUT/PARTNERS.