In 2007-08 I spent a year in Benin, West Africa, as a volunteer with the U.S. Peace Corps. Although Africa is easy to write off as a hopeless mess, there’s an important culture and movement toward economic change fueled by locals and West African nationals living abroad that is not visible in the calamity-focused news.

Michael Frank, the COO and founder of HUFRA, a precision machining company in Accra, Ghana, in West Africa, is one of those people. He has made it his mission to bring precision machining technology to his homeland by establishing one of the first CNC job shops in West Africa. Frank finished his Masters degree in manufacturing engineering in Russia and worked for 10 years in Britain. He now splits his time between his family in the UK and his homeland of Ghana, trying to get his fledgling business up and running.

Frank is attempting to do what thousands of immigrants worldwide are doing without notice from the international press—bring technology, opportunity and education back to their homelands. For instance, thousands of Turks who labored as machinists in Germany have returned to Turkey and started job shops. Today Turkey has a well-developed manufacturing core with many shops sending product back to Germany.

But does Frank have a fighting chance at being successful in Africa? At this stage of development in West Africa, with its ever-present economic, political and religious tension, is it possible to make a precision machining business not just function but thrive?

Imports from China currently fill most of the need for precision metal components in West Africa, and the product is cheap and abundant. A lack of machine-ready raw materials make start-up costs for a manufacturing business enormous and on-time delivery of product difficult. The workforce, although willing, must be trained from scratch in the art and science of machining. Frequent power outages, a lack of replacement parts and too few trouble-shooters make every small issue blow up—for example, a breakdown can require calls or even a trip to the UK for a new control. Also, steel bars must be shipped by 40’ container, a significant upfront expense.

But Frank is trying to make it all work, and claims honorable intentions. “I decided, because of the poverty in Africa, to set up some technology in Ghana,” he said during our phone interview as he was traveling to the UK to search for more start-up capital. Frank has fund raised and spent about $1.8 million so far, primarily on machines, the HUFRA building, which is located in a tax-free zone set up by the Ghanian government, and salary for the company’s 22 employees.

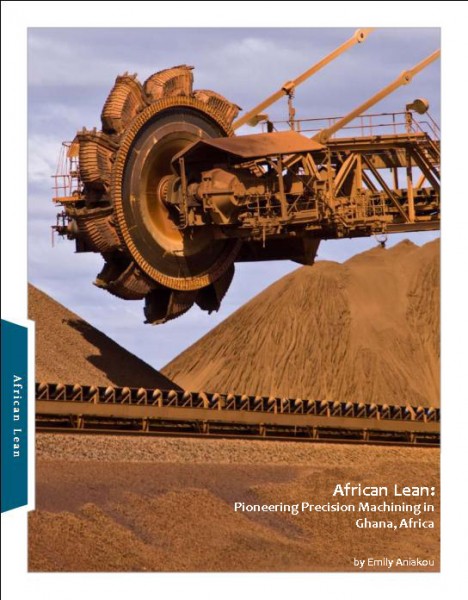

The company has four CNC machine tools; a 4-axis milling machine, a 3-axis milling machine, a 2-axis lathe with a bar feeder and a 2-axis long bed lathe for machining parts for the mining industry.About 70 percent of the company’s business comes from the mining industry, which is booming in West Africa because of the region’s abundance of natural resources, including gold, diamonds, petroleum and iron.

Earth moving equipment for the mining industry is hydraulic and HUFRA has contracts to make glands, pistons and bolts including large bolts designed specifically for mining. He also has orders for cutting shafts from chrome rod. HUFRA also make bronze and stainless bushings with complex oil grooves for AngloGold Ashanti, the second largest gold mining company in the world. Frank has taken on the responsibility of training his workers from scratch.

With no programs in Ghana to train a CNC-based workforce, Frank went to the local polytechnic institute and found technically-minded young men he could train, including two university “chaps” and one experienced mechanical engineer. With obvious pride, he said that training these young men has been one of the largest successes of the project.

Frank has shown his clients, founders, the Ghanaian government and local non-profits that Africa is a source of trainable, hard-working and technically able workers.

Not to mention, they work for cheap. Frank pays his new recruits about $200 per month, experienced workers $300-$400 per month and technically trained people and engineers$700-$1000 per month.

Frank’s assertions that few people want to invest in Africa ring true in my experience. Working on Peace Corps projects, volunteers often ran up against the same wall—no funding, no projects. It was normal for volunteers to solicit money from family and friends back home to complete their projects. But most found that surprisingly diffcult.

For Frank this lack of startup funds has been especially frustrating. “The Chinese are there [investing],” he said. But the Chinese aren’t socially minded do-gooders like Frank would like them to be.

So far he has about 10 major investors, including non-profits, government grantors and interested individuals. It’s a hard sell when his records show no profits since HUFRA officially began in 2006, and even harder when you hear him speak of the lack of the bare necessities that are needed to make sophisticated machinery work smoothly. Frank intends to create satellite locations in other countries in West Africa after he gets the Ghana location up and running smoothly. But his seemingly honorable intentions to create employment and develop the skills of the locals may be just that—honorable intentions.

Frank himself admits, “The project is big, but my [financial] backbone is slim.” He speaks of designing machinery to improve food production, create employment and reduce poverty with such passion one wants to believe he can do it all—raise $10 million in capital, train all the “chaps” in West Africa, and heck, conquer the AIDS epidemic in his spare time. But it doesn’t seem totally realistic. The world is plagued by a recession, Africa’s reputation as a place for investment is dismal and the infrastructure to successfully run a business as sophisticated as precision machining may not be fully in place in West Africa for years to come.

To watch a video inside the HUFRA machine shop in Ghana, West Africa, visit www.youtube.com/user/HUFRACT

3 Comments

i really want to join your company and learn more from your outfit. hope to hear from you soon.

The learning curve for screw machines and other machines of a similar nature, is REALLY REALLY long. And, if the machines are used, you struggle against bearings that won’t fail, but allow the spindles to float enough to get concentricity issues; stock that isn’t bad enough to fail, but has flaws that will break tools in addition to being very difficult to bring into specifications for dimensions of the finished work.; AND supervisors who will try to run cycles too fast creating problems like ‘chatter’.

Good luck.

May I suggest, an NC turret punch as your next acquisition. If you also added a paint booth, a bar break (non NC), and one or 2 welding stations, you would be in a position to produce all the tanks (eg: hydraulic oil) for your customers.

Great job on business in Ghana,want introduce u to some of my product in power transmission,check my website.Thanks