Cathy Bothe was knitting a sweater for her grandson Jack in her Kenosha, Wisconsin, home on a Sunday night in 2006, and in her words, “bitching about these crappy Chinese needles,” she was using. Husband, Kent, who had been cutting metal chips in the family machine shop for 40 years retorted, “So why don’t you do something about it?”

At that time, there was no high-end knitting needle, only the generic Wal-Mart needle. Cathy and Kent often talked about folks who restored cars. Did they go to the dollar store to buy their sockets? No, they would invest in a Craftsman or Snap-on because they understood they were buying a tool to last a lifetime.

That night, Cathy and Kent drove over to their machining facility to make the needles Cathy always wanted but could never find in yarn shops.

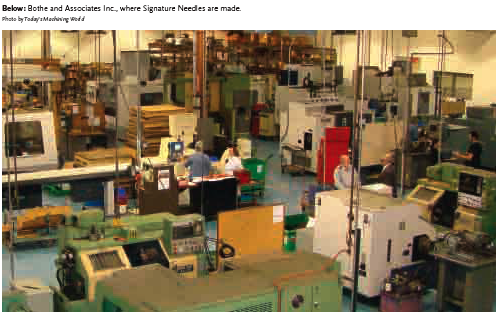

After running some aluminum barstock through a Mori Seiki AL-2 lathe, they suspected that they had the unique product every job shop owner dreams of, but most never find.

Cathy, the president of Bothe and Associates, a 59-year old shop started by Kent’s father in a humble garage, enlisted her daughter Laura and son Paul to work in the needle company they named, Signature Needle Arts. Bothe and Associates was already busy serving a broad range of industrial and medical customers, but the Bothes thought that a product that offered a superior tactile experience even at 10 times the price of generic needles from China would find buyers among knitting enthusiasts.

A business consultant could have given Cathy a dozen reasons why making a utilitarian commodity product into a piece of useful jewelry was a stretch for the machinists from Kenosha. But probably because she didn’t know what she didn’t know, she threw herself into the project with the naïveté of a zealot.

It turned out that even without a detailed business plan, possessing a plant full of CNC lathes and a million manhours of manufacturing know-how gave the Bothes an advantage in bringing their unique idea to life.

Think of the hypothetical “housewife in Duluth,” who thinks about, and maybe even pencils out, what a spectacular needle would look like. She’d likely have no clue about machining a point on a stringy piece of aluminum barstock. She probably never would have heard of anodizing or CAD/CAM. She might consider sending a product sketch to a Chinese company (that would honor the intellectual property, of course) and wait for a prototype to be mailed back to her in a week.

The Bothes were able to compress the learning curve on production but were novices at bringing a top of the line consumer product to buyers who didn’t know they had always wanted it.

Meanwhile, business in the machining world was evaporating, and the pie in the sky knitting needle effort was starved for marketing money.

Cathy and Laura Bothe decided to bring 75 pairs of their machined needles to a needle arts trade show in Chicago in August 2007, hoping to elicit a little buzz, and if lucky, sell some product.

To their amazement, customers lined up 10 deep to see the needles of their dreams. Kent had stayed home, but was on pins and needles waiting for a phone call from Cathy to report customer reaction. The call seemed to never come because Cathy and Laura were just trying to cope with the throng of buyers. This was the moment they knew they had a business, not just a sideline to the machining company.

They also discovered that a key to developing the brand was reaching the online knitting community. Most knitters are women and many of them read blogs on the Web related to their hobby. The Bothes gained tremendous exposure on a massive Web site devoted to the knitting and crocheting community called, Ravelry.com. The site now has over 513,800 registered users from all over the world. Through Internet buzz, blog mentions and displaying at shows, the Bothes quickly gained sales and credibility in the fiber arts world.

They realized that their biggest challenge is convincing people that using Signature Needles makes the knitting experience significantly more pleasurable and efficient. Stitched to that hurdle is the guilt factor. Women are often reluctant to spend money on elegant tools for themselves, though they are less likely to skimp on yarn.

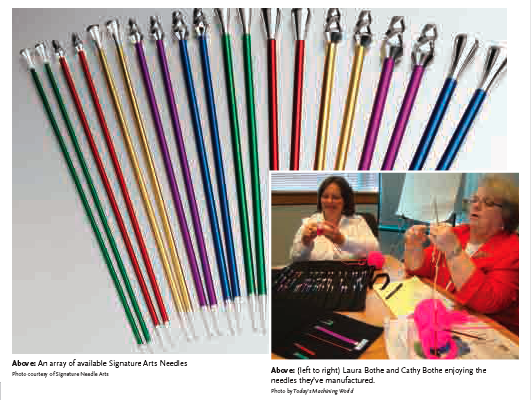

Cathy said, “If you’re going to make a gourmet meal, you must [have the best] ingredients, so we buy very high grade aluminum, all American-made aluminum. That’s made a big difference for us.” Signature Needles uses high quality grinders that get the diameters to within a thousandth of an inch total, which is important so knitters can make an accurate stitch size. They anodize in the United States, which enables them to create five lush colors—emerald green, ruby red, gold, amethyst purple and sapphire blue. The high-grade aluminum also allows their needles to be polished to a beautiful finish.

Chinese needles are made from hollow tubes of aluminum. But Cathy says you can never get quality points with hollow tubes. She says you can keep forming it and forming it, trying whatever you can think of to make the needles pointy, but you just can’t get the accuracy or the radius on the tip that Signature can achieve with their quality materials and processes.

Kent Bothe uses the comparison of buying a fancy golf putter for $200 or a Calloway driver for $300. He rhetorically asks if anybody who cares about their golf game would whack the ball off the tee with a 40-year-old Sam Snead persimmon driver.

I observed a reluctance to splurge on this type of product in my friend Janet Herbstman, who first exposed me to the knitting world. Janet is a fanatical sock knitter who could easily afford the Signature Needles, yet she told me she could not pull the trigger on a set of four beautiful double-tipped stainless steel Signature Needles because of the $45 retail price point.

Signature’s single point needles have three different point profiles; Stiletto, Middy and Blunt, which no one else has ever done. They also have three lengths available; 7”, 10” and 14”, and you can pick a decorative cap.

Single point needles sell for $28 a pair for the smaller sizes (US 1-US 5) and $32 a pair for large diameter sizes (US 6-US 10).

After our interview with the Bothes I brought back a set of double points for my friend, Janet. She woke up at 6 a.m. the next morning to try them out and immediately loved them. She says she will be buying a

lot more in the future.

Cathy says that people love to have choices, yet a typical big company has a different attitude. They say, “This is what we’re making. Here, buy it.” Signature says, “Tell us what you want.” This is why they now have a 7” needle, which no one else makes.

The Bothe family’s Signature Needle Arts story is one for all seasons, but has particular meaning now as machining companies search for a way out of a disastrous downturn.

The Bothes had a good idea—the superior needle. They had the energy, guts and smarts to pursue it in a big way. They have capitalized on their machining knowledge to make a consumer product with the precision and finish required of a medical implant. They have also utilized social media like Twitter and knitting blogs to gain a following.

“We do email surveys and have a large email list of customers,” said Cathy. They gather feedback from those and exhibit at consumer trade shows. “People come to our booth all day long,” said Cathy. “We also have people emailing us from our Web site to tell us exactly what they’d like to see—new caps, lengths, everything.”

The Bothes are worried about knockoffs, so they are running as fast as they can to build their brand, knowing that the copycats will eventually strike.

They bought a new Tsugami CNC Swiss-type lathe to machine their needles and it is now the busiest machine in the shop. In 30 months they have built a business within a business. In the cluttered world of precision machining, they have found a needle in a haystack.

2 Comments

Thanks for publishing this article. Building a brand is a very important topic that is usually ignored in this industry. But the bottom line is that building an effective brand can really impact your sales. One month after we rebranded E-Z Burr Tool Company, we saw significant increases in their bottom line. We launched the new brand at the end of March (2008)… and had the second highest May revenues in 50 years, followed by the highest June, July and August revenues (then of course the economy crashed). In addition, E-Z Burr’s website traffic more then doubled. Again, it’s just nice to see this topic covered in the manufacturing world. Branding and marketing make a huge difference and it’s nice to see someone else who has succeeded by investing in their brand.

nice story about the signature needle…i hope you will takes your machine shop for a long time… thanks for sharing me this article.. and god bless..