Today’s Machining World Archives March 2011 Volume 07 Issue 02

By Alan Earls

Today’s Machining World’s new feature, “Origins,” tells the stories of how successful technologies, companies and people got their start. This month we discuss the beginning of CNC technology, and the resistance that came along with adapting this new, and at one time radical, technology.

Despite saving labor and making possible new and better products, in its beginning, CNC machining got off to a slow start.

Automation. You gotta love it. Sure, there are traditionalists who decry the “deskilling” of the work place. Maybe they are right. But think of the billions of man (and woman) hours spent by human beings as mere helpmates to machines—manufacturing parts in an endless cadence of repetition. More than 30 years ago, John Hovorka, an early punk rock pioneer, captured this unvarnished reality when his band recorded “Bridgeport Lathe” —three minutes or so of discordant complaints about a deadening job in manufacturing, punctuated by the refrain, “The Bridgeport lathe is driving me insane.”

Allowing for some poetic license (Bridgeport never made a lathe), the song does a good job of capturing the mental state of the anonymous worker, making part after part and scarcely daring to look up to watch a girl from the front office go by, lest he lose a limb to the unforgiving machinery.

The alternative to all that hard work, automation, got a surprisingly slow start in the U.S. after the end of World War II, but then a modest boost during the Cold War, thanks in part to generous department of defense funding. In fact, according to the late David F. Noble, the author of Forces of Production: A Social History of Industrial Automation, it was in part the military’s fear of subversive elements among union members that increased the military’s interest in automation. For businesses, too, workers, with their propensity to strike, were problematic, which made automation an appealing option. Still, despite automation’s appeal, it took time and experimentation to get it right.

Though by no means the only pioneer in the field, the immediate “father” of modern precision machine tool automation, credited as such in the Machine Tool Hall of Fame, is John I. Parsons. In the late 1940s, following some promising experiments within his company; Parson proposed to develop a three-dimensional numerically controlled machine tool and persuaded the Air Force to fund the project. Eventually, however, the project was transferred to the boffins at the Servomechanism Laboratory of the Massachusetts Institute of Technology (MIT), which had established a strong track record during the war for making sophisticated gadgets. Still, it was Parsons who got the first patent.

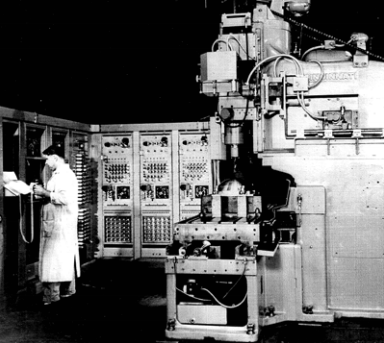

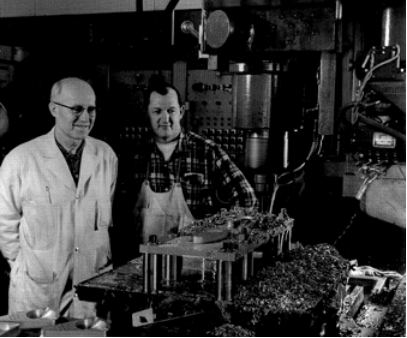

Under the auspices of MIT, the project grew in size and expense. The boys at MIT succeeded in harnessing early (and expensive) electronic circuitry to the task of running machine tools, using punch tape and later magnetic tape.

Importantly, the machine didn’t just make a series of cuts at specific points, as originally proposed by Parsons, it traversed between points, milling a smooth surface in the desired shape. The demonstration project was conducted using a Cincinnati Milling Machine Company Hydro-Tel machine dolled up with gears and servo-motors to replace the handwheels. It also incorporated a massive and complex controller, which had 250 vacuum tubes and 175 relays.

At first, the MIT project, and those of its competitors, operated with “numeral control,” which is to say lots of manual setup and programming. In fact, one study estimated that the early CNC systems hadn’t necessarily saved much labor—they just moved it to a different kind of worker. However, in 1956, work began on the APT programming language, which helped make possible full computer control and much more rapid setup. In 1959, as a demonstration project, a fully computer controlled milling machine was used to produce a commemorative aluminum ash tray (yes, once upon a time, ash trays were considered a fashionable accessory for any desk).

Still, the adoption of CNC technology by the industry was very slow, partly due to cost and reliability issues but also perhaps because CNC represented such a dramatic change. As Noble noted in his book, “The dreams of those who promoted numerical control did not translate automatically into any major industrial transformation.” At least not at the time.

But eventually change did occur. “When it comes to adopting a new technology like CNC machining, it takes time for people to see the value,” says John L. Kenshalo, Jr., today the president and CEO of a small CNC job shop in central California. But over time, people did. Maybe it’s time for John Hovorka to compose a new, more upbeat tune. Maybe about the operator of a CNC machine.