Ep. 102 – Growing a Community of Passionate Customers, with George Breiwa

On today’s episode we continue our season talking about companies who produce their own products. Our guest is George Breiwa, founder of DynaVap, a company that produces a unique type of vaporizer, using Index multi-spindles and CNC Swiss lathes. George says that one of the keys to the company’s success

How to Sell a Commodity with Soul, with Mike Pelham–EP 241

I met today’s guest, Mike Pelham, completely by chance — over breakfast at the hotel bar during PMTS in Cleveland. He knew who I was

A Letter to My Granddaughter About College

My middle granddaughter, Chava, left on a college exploration trip today with my daughter, Sarah. They will check out Washington University in St. Louis, where

Escaping Your Comfort Zone with Lean Manufacturing, Matthew Rassi-EP 216

Working in the machining industry I hear the term “lean manufacturing” mentioned a lot. But what does the word “lean” really mean in this context?

Why I’m a Machinery Dealing Matchmaker

I get fulfillment from being a yenta. Aka a matchmaker. Or “a dot connector as I like to say” in my serendipity speak.😀 I’m the

Tai Chi, Machine Tools, and ALS, with Greg Knight-EP 240

Born with no intention of becoming a machinist, Greg Knight says he was drafted into “indentured servitude” at age 16 when his father started a

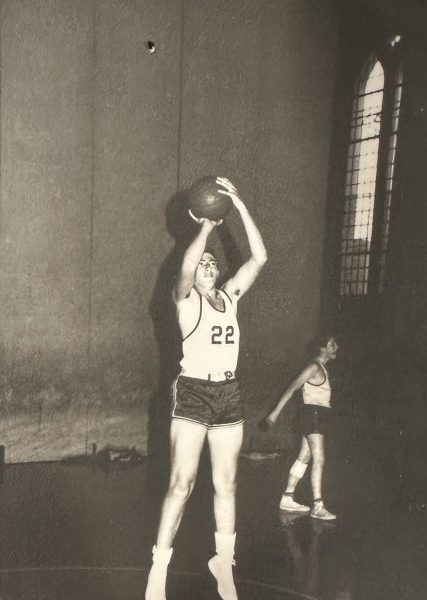

Game Changers

I imagine playing basketball if I have trouble falling asleep. I envision the basketball rolling delicately off my fingertips while shooting a free throw. March