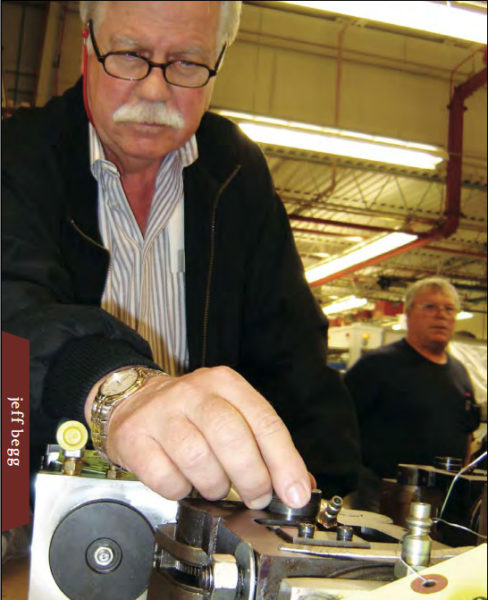

By Lloyd Graff

When you enter a machining firm which cuts millions of pounds of brass bar each year, you expect to find a line of New Britain screw machines or Davenports – bunches of almost identical automatics methodically turning out fittings.

But at Marshall-Excelsior Corporation in Marshall, Michigan, the machinery assortment reflects the eclectic taste of its owner, Jeff Begg. A little bit of this, a little bit of that. Warner-Swaseys, New Britains, Davenports, Wickmans, National Acmes; 5-spindle; 6-spindle; 8-spindle; a menagerie of screw machines bite at the brass rod, turning out Jeff’s variegated mixture of niche market non-ferrous fittings.

Begg’s mixture of screw machines cannot be easily type-cast. If it’s a good buy and it cuts brass with efficiency, he’s usually interested. Jeff Begg has built a thriving independent fittings business in southern Michigan amidst the wreckage of automotive-land by following his instincts and his own intense personal scrutiny of the fittings marketplace. Marshall Excelsior reflects the particular style and taste of Jeff Begg, who says, “I guess people say I’m eccentric,” not just because of his collection of screw machines, but because he defies the notion of the blueprint-bound engineer, even though he is an engineer by training.