By Lloyd Graff

Today’s Machining World Archives September 2010 Volume 06 Issue 07

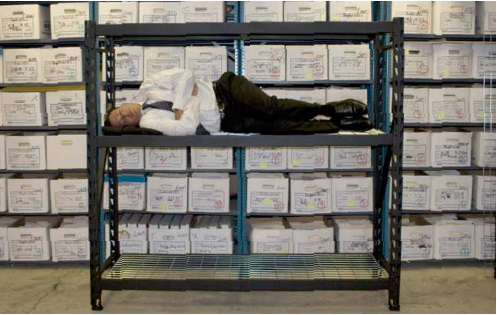

Lloyd and Noah Graff met with Mitchell Liss, president of Edsal Manufacturing Company, Inc., to talk about the issues facing an American manufacturer trying to sell to American distribution outlets and the what it’s like to be one of the largest manufacturers of steel shelving.

Lloyd Graff: Give us a little background on Edsal Manufacturing and your relationship with it.

Mitch Liss: Edsal Manufacturing opened in the 1950s and now makes industrial shelving and office furniture. The name Edsal came from my father-in-law, whose first name is Ed and whose last name is Saltzberg. At that time he worked for somebody else and was unhappy with how he was being treated, so he decided to go out on his own. He started with about $800 in a small garage and some pretty basic machinery. One of the tenets of his company since day one was to never sell product directly to an end-user, only through dealers and distributors. The company started by making steel furniture, like sewing tables.

LG: Why not sell direct?

ML: It was his philosophy to build a very strong relationship with distributors. Ed had an engineer’s mind, and I have an engineer’s mind too. We’re not sales people by nature. We have a philosophy that if we build it for the right price, the customers will be there.

LG: Who’s your biggest customer?

ML: On the industrial side, it’s Grainger. On the consumer side, our two biggest customers are Lowe’s and Home Depot.

LG: Contrast dealing with Grainger versus Home Depot. Do they overlap?

ML: They don’t. The businesses are dramatically different because Grainger has an extreme number of items with low volume [in stock]. Home Depot or Lowe’s might only have three items, but the trucks go out full every day.

LG: Is your brand important to Grainger?

ML: My personal opinion is that it’s not particularly important. I would say that on a scale of one to 10, with one being a completely generic item to a 10 being like the name GE on lighting, it would be about a four.

LG: Is your brand important to Home Depot?

ML: More so. On that same scale, it’s maybe a six or a seven. [I say that] because we have done testing in which some of those retailers tried using their own private brand and have lost a significant amount of market share. In fact, around seven years ago Home Depot changed over to their own brand, but in 2009 switched back to the Edsal brand. They wouldn’t have done that if they felt that using their own brand [was working].

LG: Where does Sam’s Club fit into this landscape?

ML: From my perspective, Sam’s Club is focused on small businesses like restaurants and other target customers who need shelving. You can contrast it with Wal-Mart, where probably 80 percent of what they carry is plastic or resin product. At Sam’s Club there are no plastic shelving units. They place themselves so they’re not competing against one another. I think they have different target customers. Sam’s Club is clearly an important player in the steel shelving market.

LG: Is all the buying for Sam’s Club done in Shanghai?

ML: In order to have an efficient buying process the buyers from the regular product side, who decide what goes on the shelf, often get their information from their global sourcing team, which assembles a group of options. What happens is that several times a year the buyers go to their buying office over in China and begin a week-long process of looking at and evaluating product. The people who organize and run those product line reviews are in the global sourcing part of the business. If you want to sell something, the best way to do it is to get to that meeting. Monday the buyer will meet with you and Tuesday they will tell you what they want brought to a finalization process.

LG: What is a product line review?

ML: A product line review is where a retailer makes their buying decisions for the upcoming year. There’s a typical cycle, maybe in the clothing industry it will be four times a year, but in our industry, it’s usually once a year for the major retailers.

LG: So you’re over in Shanghai. Do you pre-position a whole group of product there?

ML: Yes. As soon as we find out about the meeting we assemble all of our ideas. [We’ll ship] tons of product there. We will typically make it here and ship it over.

LG: You rent space?

ML: We rent a hotel room. We ship the stuff at a tremendous expense and spend $10,000 to $20,000 on space in a nice hotel. If we thought we could sell it, we’d have crystal with us. We’ll take anything, it doesn’t really matter. So when we get there the buyer picks out [however many things they want]. There’s a tremendous amount of paperwork involved. How does he want the container? How many pounds of plastic are going to be in this thing? How many dollars worth of labor is there? How much overhead? They ask you to break down the cost elements of every item. Then you wait around in China for a few days, because they’re going to call you up and say, “Hey, Lloyd, I really like this thing, but you got to be kidding me, $98? Come on now. I was thinking more like $85.” Then I say, “Oh, I can’t do it for $85. You saw my cost build-up. I said I was only making a half point more.” They’ll pick an item from you but they also pick a similar item from somebody else, then they really compare them.

LG: Why doesn’t Sam’s Club do more buying in the U.S.?

ML: Sam’s Club had [regulations] for a lot of years that really didn’t let them do business here, but we’ve overcome those. Sam’s Club is moving towards a 50/50 split with 50 percent of product from China and 50 percent from the U.S. At a place like Sam’s Club there’s an open dialogue where we can say, “Here are the benefits—you order from us on a Monday and we have to ship by Thursday. You have lower inventories. We ship to you on pallets that work for you.” In China the product is floor loaded. There are 200-pound boxes that are stacked up to get every last little one into a shipping container. Those boxes have to be more or less unloaded by hand at tremendous cost.

LG: How does selling to Sam’s Club differ from selling to Menards?

ML: It’s very straightforward at Menards. They don’t really have a buying operation outside of Eau Claire, Wisconsin, by design. Everything they do is there. We bring a whole truckload of stuff to Wisconsin, all different shapes and sizes. They have a set up room [where companies bring in their product] about once a year. They’ll have our stuff right there, 20-feet over from a competitor, with another competitor 15-feet over from them. The typical buyer from Menards will look at the product for price. They want to make sure that they’re priced right. They’re not necessarily trying to shake things up. Maybe they’ll see one new item and will try one thing. In the seven or eight years I’ve been doing business with Menards we’ve added and removed just a handful of items.

LG: What about selling to Home Depot?

ML: Home Depot’s buying has changed over the years. I would categorize it as collaborative. We launched an initiative with them about three years ago to come up with something new and different, so we tested about 10 different things in 10 different markets to see how they did. Home Depot’s buyer and Edsal developed a new product line and launched that product together with a pretty high degree of confidence that it was going to work. We are not in constant review or price negotiation with Home Depot. It’s almost impossible to ever change your price. But I don’t want to make it sound like the price pressure isn’t unbearable, it’s really hard. Steel has gone up 30 percent to 40 percent since last year. We gave Home Depot two percent off on something for a special and I couldn’t even get the two percent back.

LG: So they don’t give you any leeway for raw material shifts?

ML: No.

LG: I’d like to ask you about manufacturing Edsal products in the U.S. versus China. Do you consider it to be Edsal versus China Inc.?

ML: [In the spirit of ] full disclosure, about six years ago Edsal started its own facility in China, because I didn’t feel like I could be a credible source about doing business in China without knowing exactly what it cost to run a facility. I wanted to know exactly what the labor costs are. We have a facility and about a hundred employees there. It’s run by a guy who grew up in Virginia and lived in China for 14 years while he was in the military. So, no, it’s Edsal against every other person who can bend a piece of steel, not necessarily just China. What it really comes down to is where raw material cost is effective, that’s how you can cross off a lot of places. For example, India, where steel is pretty expensive. In China, the cost of commodities is fairly competitive. Sometimes it’s much lower there than in the U.S. and sometimes it’s about equivalent to the U.S. Of course, the Chinese government has a big hand in regulating what the cost is. Some people have firsthand knowledge of whether they subsidize steel or not. Is it illegally subsidized? I don’t know. All I know is the cost of goods coming out of China, and that as a manufacturer, you get a value-added tax rebate. On a piece of commodity coming out of China, you can get 8, 10, 12 or 15 percent back from the Chinese government on a VAT rebate, which is basically a subsidy.

LG: Do you buy Chinese steel?

ML: Yes, for the product we make in our Chinese facility, although we have shipped U.S. steel [over there]. We never buy Chinese material for products sold here. In our experience it’s not the same quality we’re able to get here. What we have used here over the last five or six years has been 100 percent U.S. steel. Our goal in China is 100 percent in-country sales. The reality is that about 95 percent of what we sell goes outside of China. We’re trying to grow by selling from there, but it’s very difficult. A year ago container costs were very, very low. Today the cost is $4,500 per container.

LG: What would you recommend the U.S. government do to help domestic manufacturers?

ML: If I were the Obama administration and I wanted to see domestic manufacturers do better I would have the TSA, who has to inspect every container coming into the country, slap on $300 for the inspection cost. If that turns into a profit for the U.S., fantastic. At least it funds our infrastructure. As an example, let’s take our number one item that I think we compete with China on by way of Costco, who basically demands that their stuff come from China. They get roughly 180 items in a container at $20 a foot. That’s $20 in freight on top of an item that they are paying $100 for. That’s 20 percent of the cost in freight. Over here, if our labor cost is, on the high end say 15 percent of product cost, but we have no freight, and they’ve already got 20 percent of the cost in freight, why should Costco be asking, “Well how could the U.S. possibly compete with China on such an item?” Even if labor were free here, it wouldn’t equal the freight costs.

LG: Tell me more about Costco, why can’t you sell to them?

ML: I’ve called on Costco for eight years and have gotten nothing but a blank stare. We’ll have a pleasant meeting where I’ll walk in and say, “I know you’re buying this stuff [in China], but we’re right here in Chicago.” I’ll leave the meeting and get not so much as an email back, just dead air. I happen to be a Costco member, and a really loyal one at that. Don’t ask me why, it kills me every time I walk in there.

LG: Why do you think that is?

ML: Obviously the current supplier, who is an importer and has a product made in China, has convinced them for whatever reason to not talk to anybody else. It doesn’t make any sense to me. I fired our sales rep here [because of it]. We don’t usually have sales reps, but in this case, I was convinced that we should have some. Costco does a lot of business through a small number of sales reps, in other words, guys who are focused just on selling stuff to Costco. They know the Costco way, know the buyers, know what they ate for breakfast, what they ate for lunch. Supposedly, they can help you. But our guys in that position hadn’t sold anything in eight years.

LG: What was your next move?

ML: I sent a letter to the head of Costco. I didn’t know who to aim for so I aimed high, right to the CEO and chairman. I laid it out just like I’m telling you. “Your members are paying too much.” I started the letter with, “How would you like to get a lower cost for the exact same product and lower your prices for your members while adding American jobs?” Then I went on to show how Home Depot has actually been priced better than Costco in some markets. I went through all that, gave them details, information and an action plan. I FedEx’d it to them on a Wednesday two weeks ago. Friday, I got a call from somebody in middle management. His questions were geared towards trying to pick my argument apart. He asked, “How could you be as cost effective as China?” I thought, “Why are you asking that question? You have a price, you can come see my facility. Heck, you can go into Home Depot, Lowe’s, Menards or Sam’s Club and see my product.” So we had a conversation and that was it. A few days later the buyer sent an email out to my rep, who I’ve since fired, saying, “Hey, has that Edsal product been tested?” He replied, “No, it hasn’t been tested by your lab, by your spec, you never asked for it to be.” This is kind of the typical stuff. So there’s been kind of a back and forth. I’ll say, “Sure, we’ll send it in for testing, give us the forms,” and they don’t give us the forms. We finally get the forms and they say, “You can send it to our testing lab in Shanghai, Hong Kong or Manila.” I say, “Excuse me, I’m a U.S. manufacturer, I’d like to have it tested here in the U.S. if it’s okay with you.” They say, “Oh, okay, we don’t normally deal with that.”

LG: How can you manufacture that efficiently?

ML: It’s all about material. We buy it right and we don’t have a lot of overhead. We look at it like we look at each one of our customers. It is an incremental business. As a company, have we had months where we’ve lost money? Sure, but we’ve never had a year where we lost money. We don’t have any debt and we don’t have any outside investors. At the end of the year whatever pennies are left over, that’s what the family takes home. If we lose money we know that every penny we lose comes out of our pocket, so it hits home. We know exactly what it costs us to make that product. In China, there are a lot of costs. There’s transportation to the port, transportation to the U.S., quality certifications that have to happen, and a whole host of infrastructure. All of that stuff doesn’t exist here, so we save on the logistical side of things tremendously.

LG: How do you buy material cheaper than your competitors?

ML: By having a really good supply base. We’re based in Chicago and there’s a tremendous amount of material available in and around here. We’re an hour away from Steel City. Almost all of our cartons for all of our facilities in the U.S. come from Chicago. As a transportation hub, it’s cheaper to ship from Chicago to almost any point in the U.S. than from anywhere else. There’s so much activity here and so many railroads.

LG: What kind of equipment do you buy?

ML: We take used equipment and make it run faster than it ever ran before. We’re really good at doing that. If we have a specific spec on steel and it comes in a little heavier or a little lighter, we can work with it. A lot of facilities can’t handle that. We’re really good at being able to handle a wide variety of material and we have a wide supply base. We’re not scared to take a position with commodities. We have the wherewithal because we don’t owe the bank anymore. If I like the price of steel, like I did last year, I keep buying it. Last year I bought as much as I could possibly store away.

LG: So you stockpile.

ML: Yes, we physically take possession of it. We’re not scared to do that. If you had a big loan the bank would look at it and say, “What if the market goes the wrong way? That stuff could be worth a lot less than it is in the books.” When we think the prices are very high, like we saw in May and June of this year, we stay really, really short. We might only have 30 or 60 days worth. As soon as we see prices come down, we go a little long. It’s not like we have a two-year supply, we might have six or nine months worth, but it gives us a little edge.

LG: Do you want to build a brand, or is that less important than keeping the commodity price down?

ML: I think if we had the choice to spend our resources on building the brand or to spend resources to take costs out of the business, we would always invest the money in taking costs out of the business. My brother-in-law, Bruce, and I both think that a lot of our customers are too picky about the finish. They say, “I want it a little grainier,” or “I want a little more texture.” We say, “It’s a shelving unit.” At the end of the day it’s a commodity. Do you care what brand lumber was used to build your house?

1 Comment

I’m appalled at the behavior of Costco. I think we should all boycott the company and it’s products. They enjoy the benefits of living in the US, yet do not even consider buying products created by Americans. Disgusting!