It’s expensive and hard to machine, but Nitinol is perfect for applications that require one or more of its special qualities: superelasticity, shape memory, biocompatibility and fatigue resistance.

A very special class of materials can “remember” their shape. After deformation you can just heat them and they return to their original form. A number of different shape memory materials have been developed, but one in particular has become a standby in many applications.

Nitinol. The name comes from the metals it’s made of and the lab where this remarkable family of alloys was discovered. NiTi-NOL; Nickel, Titanium and Naval Ordnance Laboratory.

Discovery

In 1958, William J. Buehler, a researcher at the Naval Ordnance Laboratory in White Oak, Md., started looking for a metallic alloy for missile nose cones that could withstand the high temperatures of re-entry into the atmosphere, Buehler wrote in “NITINOL Re-Examination,” an article about the alloy’s history. He selected 12 likely alloys. One day he discovered that one of the alloys, a combination of nickel and titanium, rang like a bell when struck if it was warmed above room temperature, but at room temperature it sounded dull, like lead. This attracted some attention in the lab.

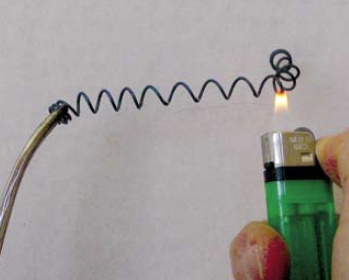

Later, Buehler prepared for a lab management meeting by bending a thin strip of the material into an accordion shape, intending to fl ex it repeatedly to demonstrate the material’s fatigue resistance, he wrote. However, during the meeting the associate director of the lab took out his lighter and applied heat to the strip. “The [bent] strip immediately extended with considerable force,” Buehler recounted. This astounded people at the meeting and revealed that Nitinol had strong shape memory.

This amazing material also exhibited at higher temperatures a quality called superelasticity. It could tolerate considerable bending without taking a permanent set.

Nitinol’s unique properties of shape memory and superelasticity result from a phase transformation within its crystal structure that happens with temperature change. At lower temperatures the structure is martensite, a weaker form, and at higher temperatures, austenite, which is stronger. In addition, martensite can also occur at higher temperatures where the material is stressed. The mechanical properties of Nitinol actually change with stress, and with relatively small changes in temperature.

Shape memory

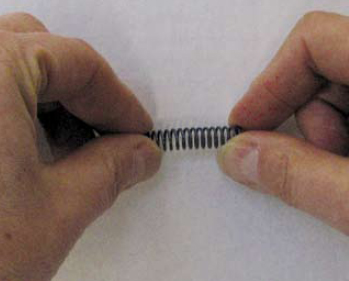

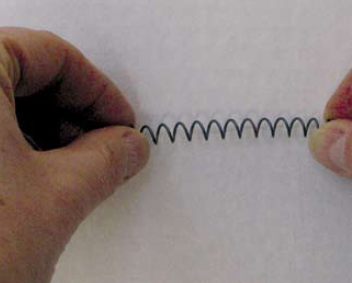

To demonstrate shape memory behavior you can deform a Nitinol item at a low temperature, really bending it out of shape. Then heat it and watch it return to its original shape, as if by magic. Nitinol in its martensitic (low temperature) state is easily bent or twisted into a new shape. Then, as it is heated it passes through a narrow range of temperatures where it changes to an austenitic structure and reverts to its previous shape.

The temperature above which the material remembers its high-temperature form is called the transformation temperature.

“The useful range of the material is typically between 0 degrees and 100 degrees Celsius [32 F and 212 F], a very narrow range when you think of metals,” said Joseph Kain, product manager, Johnson Matthey, Inc., West Chester, Pa., a supplier of Nitinol and other metals and parts to the medical device industry. The transformation temperature can be controlled by small changes in the alloy’s composition and how it is heat treated. The temperature to start or finish the transformation can be controlled within a degree or two, if needed.

To use the shape memory property once the part is fabricated, it needs to be shape set. “Setting the shape is very simple,” said Kain. “Create a form and hold [the part] in that shape. Constrain it—it has to be under load. Then you heat treat it at 500 degrees Celsius and water quench or fast-cool it.” Then, if the piece is later pulled, pushed or bent out of shape below its transformation temperature, when heated past its transformation temperature, it will return to its remembered shape.

Superelasticity

Above its transformation temperature, Nitinol displays superelastic behavior. This is due to martensite forming in areas that are stressed, even though the temperature is above where martensite normally occurs. Then, when the stress is removed this martensite returns to the undeformed austenitic state. This makes a Nitinol part very springy in feel and able to return to its original form even after huge deformation. Though Nitinol is known as a shape memory alloy, many of its applications make use of its superelasticity.

Where most metals can tolerate only a small fraction of a percent of strain without permanent deformation, above its transformation temperature Nitinol routinely can take up to an eight percent strain and afterward return to its original shape. Nitinol is also known for its fatigue strength.

Making parts

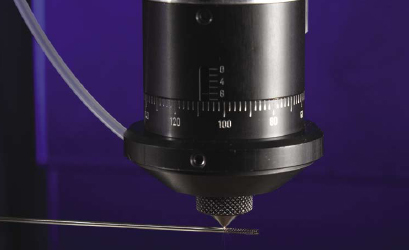

Laser cutting and EDM (electrical discharge machining) are usually the processes of choice with Nitinol. This metal can be conventionally machined, but it’s not easy to deal with.

“This is the alloy from hell. It eats tools,” said Frank Sczerzenie, chief technical offi cer, SAES Smart Materials, New Hartford, N.Y. “But we machine it every day of theweek. It’s a relatively difficult material to cut because it is superelastic. To cut, you have to go through the stress induced martensite, and that creates heat and tool wear.” Normally, depth of cut is deeper and feeds are slower to allow heat dissipation, he said.

Nitinol is a very challenging material to machine, and it requires the use of unique manufacturing and finishing technologies, said Brian Hrouda, director of sales and marketing, Norman Noble Inc., Highland Heights, Ohio, a contract manufacturer for medical devices. Though his company EDMs or laser cuts many different types of Nitinol devices and implants, it has also developed processes for Swiss turning small Nitinol components for implantable medical devices.

“From a conventional machining standpoint, grinding is a normal way to work with Nitinol.” said Kain. Since the material is so heat sensitive, you need to keep it at a constant low temperature, preferably below 100 degrees Celsius (212 F), he said.

The medical devices used to keep blood vessels open, called stents, and similar devices are often fabricated by laser cutting Nitinol tube. The process starts with a tube of very precise diameter, roundness and wall thickness, said Janet Burpee, CEO, Burpee Materials Technology, L.L.C., Eatontown, N.J., a contract manufacturer to the medical device industry. A laser cuts a complex pattern from one end of the stent to the other. Cutting might take five minutes for a 3 mm x 18 mm (0.12″ x 0.71″) stent, she said. Or, depending on the size and complexity of the part, from 30 seconds to 45 minutes.

Surface fi nish is critical on Nitinol parts used for their superelasticity and fatigue strength, said Hrouda. Any surface irregularities or micro cracks can cause fatigue failure. Processes such as electropolishing take care of this, and also can remove any heat-affected material from the part after laser cutting or EDM.

Nitinol is available in sheet, foil, tube, bar, wire and other forms. It is price prohibitive for most applications, said Kain. For example a piece of sheet stock that might cost a dollar in steel might be $400 in Nitinol. Wire is the lowest cost form. Nitinol is diffi cult to process, difficult to shape and form and diffi cult to join to anything else, he said. What typically happens is if every other option doesn’t work, they use Nitinol.

Applications

Though many Nitinol applications are invisible to the general public, some are quite familiar. Eyeglass frames made from Nitinol can be bent severely out of shape, but then return perfectly to normal. Also, some years ago, when cell phones had pull-out antennas, many of the antennas were made from Nitinol, allowing them to flex without breaking or permanently bending.

Another superelastic application, where you or your children may have experienced Nitinol, is in arch wires used for orthodontistry. The orthodontist takes a Nitinol wire and bends it, attaching it to the teeth. Because the wire is superelastic, it tries to return to its straight condition, and continually exerts a force on the teeth. This allows less frequent visits to the orthodontist to have braces tightened.

A number of lesser-known applications use Nitinol’s shape memory capability. A well-known computer manufacturer used a Nitinol device to eject PCMCIA cards. Also, Nitinol is used in couplings that join the ends of hydraulic tubing in aircraft. In a less serious application, Nitinol enables spoons from the magic shop to bend when placed in hot water.

The superelastic quality of Nitinol, along with its biocompatability, makes it ideal for making many types of medical devices that are implanted in the body. An application familiar to many of us is the stent, a device that supports blood vessels and keeps them open. Nitinol’s superelasticity allows a medical device, such as a stent or a heart valve, to be compressed into a shape that fi ts inside a catheter. The catheter is positioned at the correct location in the body, the device is released, and it returns to its original shape.

This same superelasticity makes Nitinol the only material suitable for stents used in the carotid artery in the neck, or blood vessels in the legs, said Hrouda. In these vulnerable locations, a blow to the area of a stent will cause it to deflect, but a Nitinol stent will return to its intended shape. Stents made of other materials would be subject to crushing or permanent bending by such an impact.

Surgical instruments and components made from Nitinol fill many needs, especially in minimally invasive or arthroscopic surgery. These may take advantage of the superelasticity and fatigue resistance of Nitinol. A tool that has a bend in it can be straightened and introduced through a cannula, a rigid tube. When it emerges from the cannula, the tool returns to its original shape. The surgeon performs the procedure, and then the tool is retracted back into the cannula where it straightens out again for easy removal.

The shape of things to come

Its modulus of elasticity varies with temperature, stress and strain. It’s expensive. It’s diffi cult to machine. But, Nitinol has a unique combination of shape memory, superelasticity, fatigue resistance and biocompatability. And for some applications nothing else will do.

“Go try everything else,” said Kain. “When you get to the point where nothing else works, you can afford to use Nitinol.”