Lantek, a global leader in software solutions for the sheet metal industry, has enhanced its Nesting by Attribute feature, which is released in the latest v45 of its Lantek Expert software.

Designed to enhance part handling and shop floor efficiency, this latest feature allows manufacturers to set custom nesting priorities based on operational needs.

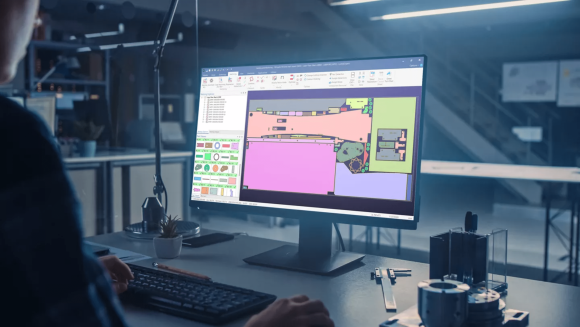

The latest Nesting by Attribute tool enables users to group and organise parts on sheet metal based on selected criteria, simplifying part identification and improving operator workflow.

Parts from the same job or production stage can be colour-coded, separated by offset zones or even divided by visible lines, making them easier to identify and remove.

Adam Ball, Commercial Director at Lantek, explains: “The latest Nesting by Attribute tool is extremely user friendly, helping machine operators quickly identify which parts belong to which job.

“With today’s high speed modern laser cutting machines, shop floor operators often struggle to sort cut parts quickly enough. Grouping parts from different jobs on a single sheet can sometimes disrupt the production flow if the parts require different post-processing steps. This new feature helps to avoid that, reduce errors and save valuable time.”

Users can now clearly define nesting priorities using any attributes stored in Lantek Expert or Lantek MES, such as delivery deadlines, follow-up processes, container type, associated job orders or assemblies. During nesting, parts matching the selected properties are prioritised, while others are placed in the remaining spaces.

This new functionality was developed as a response to industry needs and customer feedback.

Adam Ball continues: “The response has been overwhelmingly positive, with customers valuing the flexibility it offers. In some cases, full material optimisation is ideal, but in other cases, it’s far more practical to nest in a way that supports faster and more efficient part handling on the shop floor.”