Today’s Machining World Archive: August 2007, Vol. 3, Issue 03

Can manufacturing complex metal parts in high volume really be as easy as filling a mold? Read on.

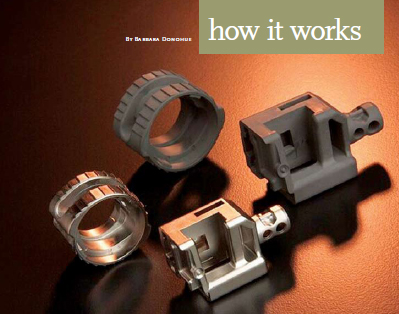

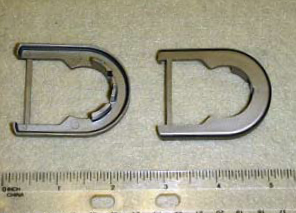

To make a complex part in metal, you can cast it, or machine it — or injection mold it. Injection mold it? Yes. Injection molding by mixing metal powder with plastic, molding it and then removing the plastic and sintering the part.

The process is called metal injection molding (MIM), or sometimes powder injection molding (PIM), and it can produce intricate parts in a wide range of metals, including steel, stainless steel, and even high-temperature alloys. MIM has been around for decades, but only in the last twenty years has found widespread commercial application. Industries that now use MIM parts include aerospace, medical, electronics, firearms and consumer products.

You may be familiar with powdered metal, or PM, parts, especially as bearings, bushings and small gears. PM parts are formed of metal powder compressed in a die and then sintered. There are several related processes that also use metal particles. MIM uses much finer powder than PM, and a completely different manufacturing process.

The worldwide market for custom MIM parts is more than $500 million, according to James Dale, vice president of member and industry relations, Metal Powder Industries Federation (MPIF), Princeton, N.J. This does not include parts companies manufacture for their own in-house use.

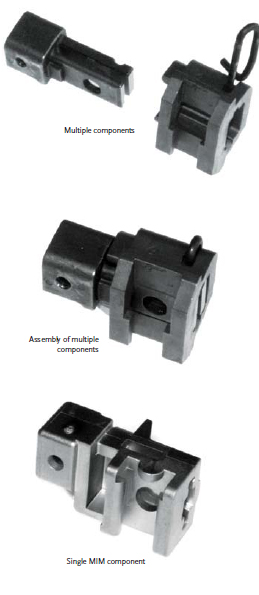

Since MIM can be used to fabricate complex parts economically in structural metals, it can provide significant cost savings to the savvy manufacturer. MIM can reduce part cost in many cases. MIM can also make it possible to replace an assembly of two or more parts with a single MIM part, eliminating the cost of assembling those parts.

From powder to part

MIM metal powder is very fine, with particles 20 microns (about 0.0008″) in size or smaller. “It feels like talcum powder,” said David Smith, senior sales manager at PCC Advanced Forming Technology (AFT), Longmont, Colo. These very fine powders are made by a number of processes, including atomizing molten metal with a high-velocity stream of gas.

The MIM process starts with mixing the feedstock, a combination of metal powder and binder. The binder is a mixture of materials such as plastic and wax materials that melt and hold the metal particles in suspension while the stock flows into the mold cavities A typical feedstock might be 60 percent metal powder and 40 percent binder by volume.

The feedstock is heated and forced into the mold cavities. The parts are removed from the mold. The newly molded parts are the shape of the final part, but larger. At this stage they are called “green” parts.

The next step is called first stage debinding. This removes most, but not all, of the binder from the part. Debinding can be done with heat (thermally) or by a chemical process, either with solvents or with chemicals that react with the binder.

After first stage debinding, a small amount of binder remains to help the part hold its shape. The part is now a “brown” part and is about 40 percent porous.

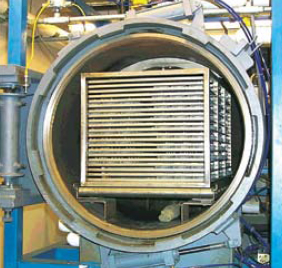

Finally, the parts are set on ceramic trays, supported by fixtures if necessary, and placed in a furnace to remove the last of the binder and sinter the parts. Sintering may be done in a vacuum or in a hydrogen or other gaseous atmosphere, depending on the requirements of the metals. For example, metals that form oxide on the surface of the particles might be sintered in a hydrogen atmosphere to remove the oxide layer.

In the sintering furnace, the temperature rises until the remaining binder is gone and the metal particles approach 90 percent of their melting temperature, at which point they join together. After sintering, most MIM parts end up at 95 to 98 percent of full density; they contain 2 to 5 percent of equally dispersed voids (pores). They have a smooth surface finish, typically around 32 RMS (root mean square roughness).

MIM parts are often used as-sintered, but machining, heat treating, plating and other processes can be applied to the sintered part. Parts that distort during sintering can be coined or otherwise straightened afterward. In special applications where 100 percent density is required, a hot isostatic pressing (HIP) process is used.

Economical for small, complex parts in high volumes

Since MIM parts are made in precision injection molds, similar to those used with plastic, the tooling can be quite expensive. A MIM mold will cost about 20 percent more than an equivalent plastic mold, according to Tim McCabe, technology development manager, Kinetics Inc., Wilsonville, Ore. The MIM molds need to fit together more tightly because of the properties of the binder compounds. Also, said McCabe, in general, part tolerances tend to be tighter for MIM parts. The cost of making injection molds varies tremendously and depends on many factors, but tens of thousands of dollars would not be unusual for a multiple-cavity mold for small precision parts.

To make MIM economical, a company would need to amortize the tooling cost over all the parts made. So MIM is usually used only for higher-volume parts. At his company, “ ‘low volume’ is less than 10,000,” said McCabe, and typical quantities can run to the hundreds of thousands, or even millions.

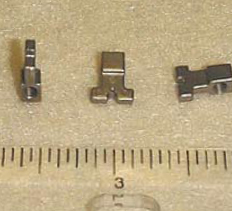

The MIM process works best with smaller parts. Some typical maximum sizes listed by different MIM shops are 100 to 200 grams (3.5 to 7 ounces), with a recommended size of 50 grams or less. One MIM manufacturer mentions its “rule of thumb” on its web site: you can make MIM parts about the size of your thumb.

The mold is designed over-sized to allow for the expected shrinkage of the part. Tolerances on completed parts normally run in the 0.003”/inch range, with closer tolerances possible. On longer parts, feature-to-feature tolerances can be challenging. In this case, “you could mold in one hole and drill the other one,” said McCabe.

MIM’s niche in the manufacturing world is small, complicated, high volume parts. Some parts may not be economically viable without MIM. “MIM does not compete with pure manufacturing,” said Smith. If a customer needs a part that could be a “straight screw machine part, a stamping, or a powdered metal part, we’re not going to compete.”

Material mystery

The mechanical properties of MIM materials can be close to those of wrought materials on ultimate tensile strength. The small amount of porosity remaining in completed MIM parts may impair dynamic properties such as impact and fatigue strength, as compared with forged or wrought parts of the same alloy. However, the overall uniformity and fine microstructure of the material can make for improved or more consistent properties.

“One advantage that MIM material has versus forged material is the lack of texture or directionality of properties,” said Maryann Wright, engineering supervisor at the Powder Metal Products Division of Remington Arms Company, Ilion, NY in an e-mail interview. For wrought metals, the mechanical properties in the direction of rolling can be different from the same properties in the transverse direction. MIM parts are usually quite uniform in all directions.

MIM can also have performance advantages over cast metals, which may have larger, irregular pores and a non-uniform chemical composition due to the melting/ solidification process.

Learning to MIM

Most of the design guidelines for MIM parts are the same as for injection-molded plastic parts. The same recommendations apply for uniform wall thicknesses and ribs for strengthening. For MIM parts, you also need to think about how the part will behave during sintering, and include design features to prevent sagging or other deformation. Special fixturing can support the part during sintering, or the part can be straightened afterward, but ideally it should support itself and not deform in the sintering furnace.

Material selection offers its own challenges. When working with a MIM house, you should specify the mechanical properties the part needs to have, and let your MIM supplier help you select the material on that basis. The alloy you end up using for a MIM part may not be the same one you might specify for a cast or machined part.

Experienced MIM engineers can help fine tune a new design and select the right material. Also, if you’re changing from a cast or machined part to a MIM part, or if you’re creating a single molded part to replace an assembly, seek out the engineering expertise at the MIM house. “The sooner you get the MIM designers involved, [the better]. They may come up with solutions you may not have considered,” said Dale. “[. . .] A MIM engineer sees problems every day that the design engineer has never had to consider.”

A lot of design engineers aren’t very familiar with MIM, said Dale. They may have heard something about it in school, but may not have gone into any depth on the subject.

To help remedy this lack of exposure, Advanced Forming Technology conducts a “hands-on MIM school” four times a year. Interested engineers, and a few purchasing people, come to the plant and spend two days learning about MIM. They experience first-hand how to mold, debind and sinter parts, and come away with a deeper understanding of what MIM can do.

Though metal injection molding is a powerful parts-making technique, it is not the ideal method for making every part in every application. For some high-volume products, however, MIM can solve design problems or save assembly costs in ways not possible with other manufacturing technologies.

2 Comments

Pingback: Geissele SS Spec

Pingback: Metal Injection Molding: Under-appreciated and Underused? - QualityInspection.org