Delcam, the world’s leading specialist supplier of machining software, will demonstrate its integrated CAM system for SolidWorks at the SolidWorks World 2010 exhibition to be held in Anaheim, California, January 31st to February 3rd. The initial version of Delcam for SolidWorks will include the company’s industry-leading technology for drilling and two- through five-axis milling. Future releases will cover the full range of machining operations, including turning, mill-turn and wire EDM.

Delcam for SolidWorks will, of course, be fully integrated into the SolidWorks environment so that the program looks and behaves like SolidWorks. It will offer full associativity so that any changes in the CAD model will be reflected automatically in the toolpaths. However, this associativity will be more intelligent than that offered in many other integrated CAM systems. Delcam for SolidWorks will not simply modify the existing toolpaths but will also review the choice of cutting tools and machining strategies, and change them if necessary.

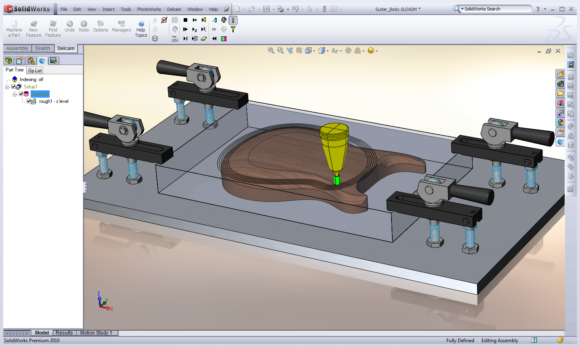

All toolpaths generated with Delcam for SolidWorks can be checked by the integrated simulation module on the computer before being passed to the machine tool. Finally, the software comes with Delcam’s full range of post-processors to allow fast accurate data transfer to all leading types of machining equipment.

Delcam for SolidWorks marks a new direction for Delcam. Previously, the company has supplied all of its machining software as stand-alone systems that can be linked to any CAD program. “We have received many requests from customers that want to be able to undertake their CAM programming from within the SolidWorks environment,” explained Tom McCollough, Vice President of FeatureCAM Development,. “Delcam for SolidWorks provides direct access to Delcam’s world-leading CAM algorithms from within this leading design software.”

More on what is inside Delcam for Solidworks

Delcam for SolidWorks combines the benefits associated with Delcam’s PowerMILL and FeatureCAM CAM systems. It is based on Delcam’s proven machining algorithms that are already used by more than 30,000 customers around the world. For example, the software will offer PowerMILL’s exceptional speed of toolpath calculation, plus all of advanced strategies for high-speed machining, including trochoidal roughing, spiral finishing and Delcam’s patented Race-Line Machining technique. These strategies ensure increased productivity, maximum tool life and immaculate surface finish, even when cutting the hardest, most challenging materials.

At the same time, Delcam for SolidWorks will have the same strong focus on ease-of-use as FeatureCAM, including all of the knowledge-based automation that makes it so consistent and reliable. Most importantly, the software will include FeatureCAM’s Automatic Feature Recognition system which automatically extracts detailed feature information from the SolidWorks model. The system not only recognizes holes and pockets within the model but also groups similar holes by size and type automatically, and indentifies draft on pocket walls, and any fillets or chamfers within the pocket. Once the features have been identified, Delcam for SolidWorks undertakes automatic selection of cutting tools, machining strategies, and feeds and speeds, to complete the programming operation.