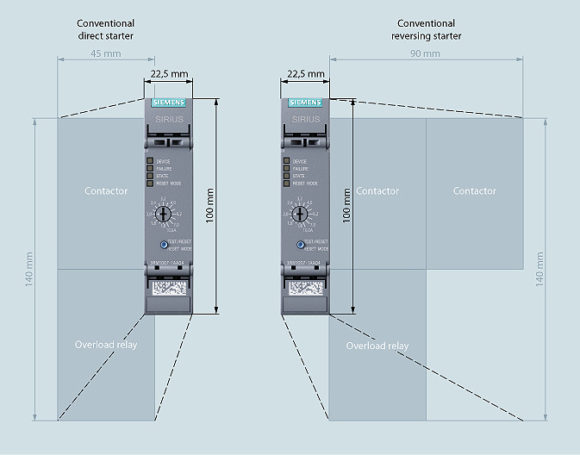

Siemens Industry, Inc. has added the significantly compact Sirius 3RM1 hybrid motor starter to its switching technology portfolio. The starter is designed as both a direct-on-line starter and a reversing starter with integrated overload protection for smaller motors with a rating of up to 3 hp, used, for example, for fans, pumps and lifting gear, as well as in machine tools. At just 22.5 mm wide, the Sirius 3RM1 reduces space requirements in the control cabinet by up to 82 percent. The motor starter facilitates the requirement in modern plant and machinery construction for space-saving components.

Besides its narrow profile, the Sirius 3RM1 is also characterized by economical hybrid technology that combines the benefits of semiconductor and relay systems in one device: the low-wear semiconductor components are responsible for connection and disconnection operations while an energy-efficient relay system is used during operation. This extends the motor starter’s service life and reduces maintenance demands.

Siemens also offers a special infeed system for the new motor starter which permits fast and simple implementation of group motor starter installations. As the main circuit is centrally connected to the infeed system, there is no need for separate wiring of the individual motor starters. The assembly with the infeed system is particularly suitable for conveyor systems in which a large number of motors are used on one conveyor belt. When maintenance is required, the individual motor starters from an existing assembly can be replaced with little effort thanks to the infeed system. Moreover, the motor starters can also be simply bussed in the control circuit using a device connector, so there is no need for extensive manual power supply wiring between the motor starters in the assembly. Wiring errors are reduced, and commissioning of the system is completed in less time.