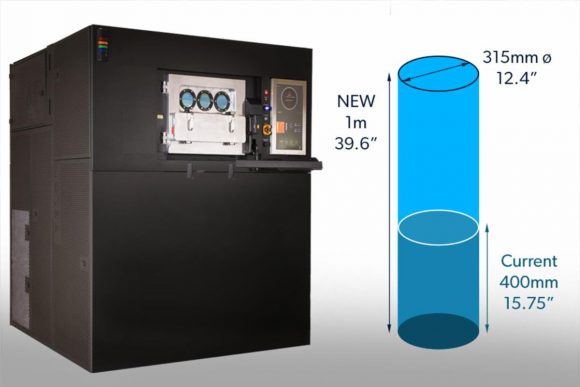

This spring, VELO3D announced its next-generation Sapphire system that will offer a vertical axis of one meter, the tallest build envelope in the powder-bed fusion category. The new system architecture will be available later this year. Knust-Godwin, an established precision-machining shop that is looking to expand into new industries, recognized the value in the industrial 3D printer and has signed up to be VELO3D’s first customer. Mike Corliss, Vice President of Technology at Knust-Godwin, and Zach Murphree, Vice President, Technical Partnerships at VELO3D, are working together to bring the Sapphire 3D printer into Knust-Godwin’s fold of high-end manufacturing processes.

Zach, why did VELO3D decide to increase the height of the new Sapphire rather than expand the overall build volume?

Murphree: When we designed the architecture of the original Sapphire 3D metal printer, it was always our intention to extend the Z-axis for future machine generations. There are several different applications where having a taller system would be beneficial—even if the width or diameter were not changed. There are some obvious applications in aerospace and other industries where taller, tubular-shaped components would be clearly beneficial. You can do some really amazing things around light-weighting, stiffening, and part-reduction when you increase the height.

Another reason it makes sense to increase the z-height without changing the diameter of the build volume is that we can do so while maintaining identical process recipes across the two machine configurations. Often when these systems change size or number of lasers, the customer is left to re-qualify the new system with new process recipes. Velo3D is keeps its customers from experiencing this pain by maintaining a consistent support-free process across our platforms.

Mike, Knust-Godwin’s heritage is in precision machining; over the past 8 years, you’ve made a significant investment in metal additive manufacturing. Tell us about why you continue to invest in AM.

Corliss: This is a question I get all the time: “When can we go taller?” Printing tall, complex parts is one of those things at Knust-Godwin that we’ve wanted to do for quite a while. It’s part of our vision for the future.

Of course, we still produce most of our products with traditional, subtractive manufacturing processes. But we have come to realize that we can apply this new technology to a lot of the parts we produce. We’re sure it will help reduce machine time, queue time, and even help reduce geometry—including the weight of the part and the size of the part—in some areas.

So we’re excited about having the 1-meter-tall Sapphire from VELO3D. AM is something that we’re very comfortable with doing, and we can predict what the benefits will be when we can print components up to one meter in height.

Mike, what are some of the advantages offered by metal additive manufacturing?

Corliss: The whole idea is to really take advantage of improving the interior geometry of some of these taller parts. With machining, we approach such parts in a very linear manner. We drill the holes from the end of the part, drill down the length of the part, and then connect it with all sorts of ports and features from the outside. With AM, though, we can change that internal geometry, take advantage of it, condense the part, and then create it with a single manufacturing process.

There are so many potential benefits. The overall length of the part may change for the better. The part may become shorter because you can take advantage of some of the geometry and of some of the internal features. And you may be able to arrange more features around the part in different orientations. Basically, you can improve the part in so many ways because you are using an alternative way to manufacture it.

Does the taller build volume offered by the new Sapphire make it possible to print integrated assemblies more easily?

Corliss: Certainly. Suppose we have an assembly that consists of maybe six components stacked up vertically. The entire assembly is just under a meter in height and takes up a lot of space, requires considerable time to manufacture, and costs a lot to produce using subtractive manufacturing techniques. If we use AM, however, and print the geometry that accomplishes all six functions in a single part, we can eliminate the purchasing and manufacturing for the six individual components and work on the final, single assembly instead. Plus, we have created a far more elegant solution for our customer that offers all kinds of benefits, such as reduced cost and improved reliability.

Mike, what kinds of parts are you printing?

Corliss: Knust-Godwin is known for our precision machining in the high-end of oil & gas industry applications, what we call the MWD/LWD product line. That includes “measure while drilling” and “logging while drilling” products, along with wireline products. These are on the drilling side of the business, with alloys like Inconel, titanium, etc. They’re not the easiest materials to work with, but they are essential. Nickel alloys specifically have typical properties that we need in the oil and gas industry for high corrosion resistance and strength. Also important is the fact that these alloys are non-magnetic, which is beneficial because we have a lot of electronics that go into the products that we build.

Zach, do you see these nickel alloys being applied to other industries as well?

Murphree: Yes, absolutely. I think there’s a lot of very good overlap with other industries that are early adopters for additive, such as aerospace—which shares those requirements for intense thermal management of extreme temperatures, complex geometries, and expectations of cost-control and rapid delivery of parts.

VELO3D got its start in more propulsion-focused applications, whether that was for rocket engines or turbo pumps or gas turbine applications. And, in those, you’re really looking for corrosion resistance and the ability to function in high-temperatures. Inconel and other nickel super alloys lend themselves very well to that.

Just as Mike said, we’re seeing that the oil and gas industry is a really good application for these materials. Not just in the downhole tools, but also in flow components. So if you’re looking at compression technologies, industrial gas compression, or valving for wellhead applications, these are all places where you want to use high-strength, corrosion-resistant alloys. Inconel is a really good choice in that regard.

Zach, tell us a little about the Sapphire’s support-free capabilities and its impact on post-processing.

Murphree: This is a key differentiator for VELO3D. Existing power-bed systems often require supports for any surface below 45 degrees. Sapphire printers separate themselves from other solutions with their unique ability to print low angles and overhangs down to zero degrees horizontally, as well as large diameters and inner passageways up to 100mm without the need for supports. This greatly reduces post-processing and allows for extreme freedom when designing and building highly complex components for a variety of industries.

How will support-free printing be beneficial to Knust-Godwin customers, Zach?

Murphree: One of the commonalities we see in many of the industries served by Mike’s customers is that complex internal fluid passages are often required. With support-free printing, the flow of fluids and gasses through a component is optimized. Whether you have a shrouded impeller or a diffuser section or a hydraulic wireline tool, the support-free structure of those fluid passage areas provides a tremendous advantage. This will be extremely beneficial to Mike’s customers at Knust-Godwin.

Mike, how will the support-free capabilities of the Sapphire printer impact your time spent post-processing?

Corliss: All the products that we make require some kind of post-processing—such as hipping and heat treating—to get the mechanical properties that we are looking for. Post-processing with traditional manufacturing techniques can be time-consuming and expensive. I would rather take the laser powder-bed technology, print the product to the near net shape, reduce as much post-processing as possible, and then do the hipping and heat-treating.

But VELO3D takes it a step further with their support-free printing feature. With other AM systems, some products may need to deal with those supports during the post-processing phase. Obviously, this, too, can be time consuming and costly. With far fewer supports to deal with, however, the process is streamlined. We can build a better product faster and at a lower final cost.

What do you see as the future of AM in your industry, Mike?

Corliss: Subtractive manufacturing will most likely always play an important role in our industry, but as additive manufacturing systems like the new Sapphire become more robust, the potential to use 3D printing for complex products will become unlimited. It could revolutionize the way our clients put together their systems by making their component parts smaller, lighter, more durable, more functional, more reliable, and less expensive. I am very excited about what we are going to do with this technology. It will enable us to offer more capabilities for a wider variety of industrial applications.

How do you view the growth potential of this technology, Zach?

Murphree: We can’t be happier that a company like Knust-Godwin has become an early adopter of our technology. We look forward to doing great things with them this fall, and then expanding into new markets and new industries very quickly after that. Let’s not forget that what we have here is the tallest production 3D printer in the world at one-meter in the Z-direction. That’s significantly taller than the next highest offering. What a company can do with that extra height is going to be simply extraordinary. It will open new doors to a huge variety of applications that can be served by 3D printing.