Have you ever wondered what it takes to manufacture luxury watches that cost tens of thousands of dollars? This is the episode to find out!

Last week I reconnected with Josh Shapiro to tell him about a used Willemin 408MT Graff-Pinkert had for sale. He told me that he was extremely excited for his new line of watches coming out that he has been working on for years. He is finally going to be producing the entire movement in his watches.

Please have a listen to one of our most popular interviews on the show!

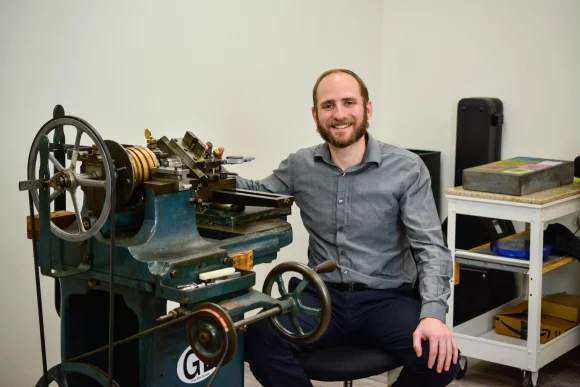

Our guest on the podcast today is a machinist, entrepreneur, and master craftsman.

Josh Shapiro is the owner and founder of JN Shapiro Watches, one of the few high-end luxury wristwatch makers in the United States. His latest line of watches will be priced at $70,000 dollars and up.

His operation uses the most state of the art CNC Swiss and turn mills, as well as manual turning technology developed as far back as the 1500s!

Listen to the podcast or read the highlights to learn how Josh is producing watches like nobody else has in United States for last 50 years.

Highlights from the Interview

Noah Graff: First, explain your company, JN Shapiro.

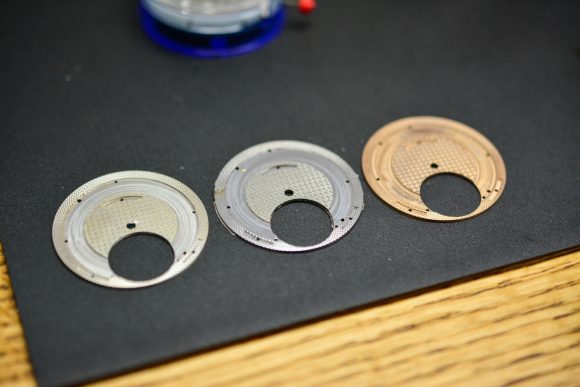

Josh Shapiro: We make high-end luxury wristwatches. We’re one of the very, very few companies in the United States that manufacture watches. We started out just making the faces of the watches. Our expertise is with something called Guilloche, which is doing engraved geometric shapes on the faces of watches, and that’s done using non-motorized, very old school machines. They’re really special. From there we moved on to making our own cases. Now we are very close to having our first prototype completely in-house movement done.

Graff: How much do the watches cost?

The price was $30,000 to $40,000 depending on the case material. The new series that we’re going to launch soon is $70,000 up to about $85,000, depending on material and customization.

So they’re very expensive, but we put in about 400 to 500 hours on each timepiece. So much time goes into making each one of those watches.

Graff: How did you get into watchmaking?

Shapiro: I just had a love of old things, so I ended up becoming a history major and then becoming a teacher.

I walked into a local watch store here in Los Angeles called Feldmar when I was about 25, and just fell in love with watches.

One of the first watches I saw was a Skeleton Chronograph watch. There was just so much going on there. It was so fascinating to me. Watches are mechanical. Watches are a really beautiful thing. It’s wearable jewelry that’s functional. It’s fascinating how the gear train flows together. How the escapement functions, the pendulum, just the whole interplay of all the pieces.

While I was a teacher and principal, I was doing watchmaking as a hobby. Then around 2015, I purchased a really nice set of Guilloche, or engine turning machines, and that allowed me to do professional level work. I started producing watch faces, watch styles for other watchmakers, and started thinking in the back of my head of launching my own brand.

Around 2018, I launched my first series, and that’s when I started really reducing my role as a principal, until finally leaving completely two years ago.

Graff: Explain engine turning

Shapiro: The concept is there are cams made out of bronze on the spindle of the machine, and those cams are rocking against the stop. As the spindle is turning, it’s creating these geometric patterns. Then you can phase the cam, independent of the workpiece, and you can create these really beautiful geometric shapes.

It’s an old art. Engine turning machines have been around since the time that lathes came into existence, around 1500.

I have a number of them. The first one I bought, I scraped together every cent I had to afford it. Then, then I ended up selling that set of machines and buying another set of machines. The second set of machines cost me around $30,000. I didn’t have that much money, so I had to sell my 67 Mustang Fastback to afford it.

Graff: How many staff do you employ for making the watches?

Shapiro: It’s me plus seven. I’ve taught everyone in the company how to do engine turning. I have one trained CNC machinist. I have another watchmaker who is turned into a CNC machinist. I have three other watchmakers who are doing various watchmaking tasks and manual machining tasks.

I have one person who’s a trained jeweler, who has pursued a whole career in hand engraving, and one admin. So everyone has a really great skillset and really enjoys making things.

Graff: Tell me about the various machines in your shop.

Shapiro: My first big CNC machine, which we still have, is a Haas office mill. That’s actually a great watchmaking machine, and there’s a lot of people in Switzerland that have these Haas office mills because they’re really, really accurate.

Then we got a Hardinge, HLV, which is like the premier tool room lathe.

And then we picked up the, the (Citizen) L20 from you that was to practice on before we got our new shiny L12, which is getting here Wednesday.

The big machine that we got this year was a Kern Evo. Kern makes the most accurate milling machines on the planet.

It’s a sub-micron machine. We can’t measure sub-micron here in our shop, but it’s nice to know that we’re working with the machine that accurate, that precise. It’s the first Kern Evo used for watchmaking in the US, which is really exciting.

Graff: Explain the watch movement

Shapiro: A movement is the guts of a mechanical watch. It’s everything inside of it, just like a car engine and transmission. There are some [watch] brands in the United States that do cases and dials, and some purchase everything from Switzerland. They’re just designed in the United States, like Shinola watches. You know they’re importing a good chunk of all their stuff. They got in trouble with the FTC for saying it was American made.

Slowly more is being done here. Our watch that we’re working on is the first time since the sixties that all the parts, all the little parts, everything are made in the United States.

The old series, the Infinity series, that we sold out on, we were making the case, the hands and the dial. So not the movement of the watch.

That was according to plan. I did the Infinity Series to have the funding to grow the company enough to be able to make the movement. Some people make the mistake of trying to do the movement, which is the most difficult thing, right off the bat. And if it’s not a critical success, then they’re out of business.

Graff: Why do people buy expensive watches?

Shapiro: I guess the best example is if you look at the car world. You can buy a Toyota or Honda, and it’ll get you from point A to B, and you can also buy McLaren and it’ll get you from point A to B. From the outside observer, they say, okay, the McLaren looks cooler and rich people buy it.

But then you get into the engine. You know the car goes fast—very, very fast. There’s a ton of engineering that goes into the car to make it be able to do that.

The quality of the parts that are in the car are produced at a much higher level than in a car that’s mass produced. It’s the same thing for a watch. It tells the time, but the quality and time that we put into each and every one of the parts is astronomic.

[A watch] is something that’ll last hundreds of years. It’s a piece of art, and it’s functional art that you can wear on your wrist. Art is the spice of life. It’s not something that’s necessary for you to eat, or live. But it’s what makes our civilization special beyond just being a toy for wealthy people.

When someone sees a work of art it’s inspiring, and that’s what we do with our watches. They’re more than just time telling devices.

Question: What is your favorite watch?

Podcast: Play in new window | Download

9 Comments

Listen to the podcast last night and finished it on my drive to work this morning, one of the best you have done thus far! Great job, keep up the good work!

Listened*

Hi Fabrizio!

Thank you so much!

That feels so good when I hear that!

Are you a watch guy?

Do you have a favorite watch? Too much money for me. 🙂

I assume you are podcast guy. Who would you like to hear interviewed?

All the best,

Noah

Not a “watch” guy, I guess. My Seiko lives with me in the shop. It isn’t a fashion accessory. I do prefer a watch to having to check a phone to know the time. I can admire the workmanship from “afar”, about $70,000 away.

FYI Seth,

Josh says he can’t afford the watches and prefers to spend that kind of money on machine tools. He uses an Apple Watch!

Mechanical watches are works of art. These are statement time pieces.

You want accuracy? Stick to your smartphone or a quartz movement. I just bought a Seiko watch…solar, perpetual calendar, and synchs 3 times at night with the Ft. Collins, CO atomic clock for UTC time. When I opened the box and made the initial setting for my time zone, it was amazing seeing all of the hands whir around setting to the exact time. Paid $325 for it.

Hi Robert!

True. Josh uses an iPhone. In the interview he talks about how the iPhone clock is based on the atomic clock.

I’m not rich enough to justify buying a watch this expensive, even if I wanted to. I’d have to get payments!

It’s still interesting. That one cannot lie. I suppose a watch that costs a few hundred thousand requires less maintenance than a McLaren.

Thanks for commenting! I think it’s time we have you on the show!

Great episode, Noah!

Would love to visit this Josh’s facility if I ever in that part of the word

Thanks Erez!

So glad you enjoyed it.

He is an MOT so it’s even better! 😂💪

All the best.

We are supporting you guys over there.