by Barbara Donohue

Today’s Machining World Archives October 2010 Volume 06 Issue 08

Picture a band saw, but instead of a saw blade there is a thin wire, positioned vertically or at an angle, with which you can cut in any x-y direction. This is wire EDM (electric discharge machining), a process that can cut any electrically conductive material, hard or soft, even carbide or diamond. Wire EDM cuts without contact, burr free. Because the wire is so fine, you can cut small-radius inside corners or even narrow slots. Because the wire never touches the work piece, there are no cutting forces, so you can cut thin stock, fine ribs, or very delicate forms.

Wire EDM has been used in industry for about 50 years. Modern wire EDM machines incorporate CNC controls and built-in sensing and intelligence, making them increasingly capable and easy to use.

Zapping material to remove it

Back in the 1700s, English scientist Joseph Priestly discovered that he could erode away metal with electric discharges. However, it wasn’t until World War II that the process became useful when two Russian scientists, a married couple by the name of Lazarenko, developed a controlled method for using electricity to remove metal. In the early days, EDM was used mainly to remove broken taps and drills by feeding an electrode into the center of the broken tool. In addition to wire EDM, the same principle is used today in diesinker, or vertical EDM, which makes a cavity in the work piece using a copper or graphite electrode in the desired shape. An EDM drill uses a tubular electrode to “burn” a hole through conductive material.

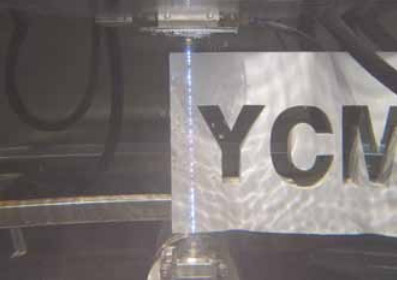

Wire EDM, which came into commercial use in the 1960s, uses a wire, stretched taut, as the electrode. Usually the work piece and wire are submerged in deionized water. The water acts as a dielectric (electrical insulator) until the electrical discharge happens. As the wire approaches the work-piece, at some point the distance becomes small enough and the voltage great enough that the dielectric breaks down and allows discharge of electricity—a spark—between the wire and the work piece.

The electric discharge heats a small portion of the work-piece to thousands of degrees. The dielectric becomes an ionized gas, or plasma, ballooning out at high pressure. The plasma bubble collapses, forcing the melted material to scatter into the dielectric fluid, leaving a small crater in the work piece. At the same time, a little bit of the wire erodes. This discharge process repeats rapidly, up to 250,000 times per second. Thus, the metal near the wire is removed and a cut forms along the wire. A flushing flow of water cools the wire and removes the particles produced.

Because the wire is also eroded somewhat in this process, a wire EDM machine constantly feeds fresh wire from a spool. The machine chops up the used wire and leaves it in a bin for recycling.

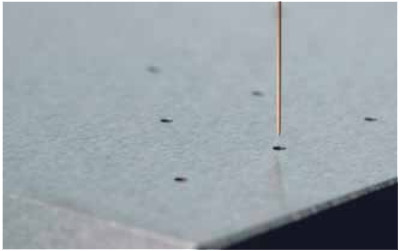

To cut an internal form, you have to provide a pilot hole. This can be done with a conventional drill or with an EDM drilling machine. The wire is threaded through the hole to start. Modern wire EDM machines provide automatic threading. A water jet or air jet guides the wire through the work piece. The machine automatically makes the necessary mechanical and electrical connections. If the wire breaks while cutting a part, the machine senses the break, re-threads the wire, and resumes the cut where the wire broke.

The wire

Critical components of the EDM process are the wire and the dielectric water. Wire comes in several materials and a range of diameters, with 0.010” or 0.012” most commonly used, said Alicia Smith, territory sales manager at Belmont Equipment & Technologies, Madison Heights, Ill.

The wire used for most applications is made of brass, said Brent Pasquantonio, territory sales manager at Belmont. If you need higher performance, you might choose a zinc-coated wire for increased speed and improved surface finish. The zinc coating allows the wire to tolerate higher heat and helps keep the spark more consistent.

Heat-diffused, annealed wire—brass wire enriched with zinc—can tolerate more heat in the cut. To wire EDM a thick part, which would not get much flushing water to the wire at the center of the work piece, you would use a high-performance wire, Pasquantonio said. It could withstand the heat, maintain consistency throughout the cut and resist breakage.

Today’s EDM machines sense the wire and cutting conditions and adjust the cutting speed accordingly, Pasquantonio said. “Just changing the wire can give you speed improvement,” he said, without making any other adjustments. In one application, for example, brass wire made a cut in 10 hours. But diffused, annealed wire reduced that to seven hours, without changing any settings. The process could be optimized by adjusting settings on the machine, he said.

The improvement is very application dependent, Smith said. “Some improve more, some less, but there’s always a dramatic shift. Even 5 percent improvement can make it worthwhile.” Any type of wire will cost only a few dollars per hour, and a high-performance wire can more than pay for itself in increased production, said Pasquantonio.

Other types of EDM wire are available for specific applications. Implantable medical devices, for example, must not encounter copper, so molybdenum wire is used. Break-resistant steel-core brass wire is used for applications where the wire is under high tension.

The water

To get the best performance from a wire EDM machine, you need to maintain the water’s cleanliness and correct conductivity. In the EDM process some of the metal goes into the water as small particles and some gets dissolved in the water. The water recirculates through a two-part water treatment—a filter to remove particles, and a deionizing res-in to remove metal atoms from solution. Good maintenance practice includes periodically replacing the filter cartridges and sending the deionizing resin out for regeneration.

Applications

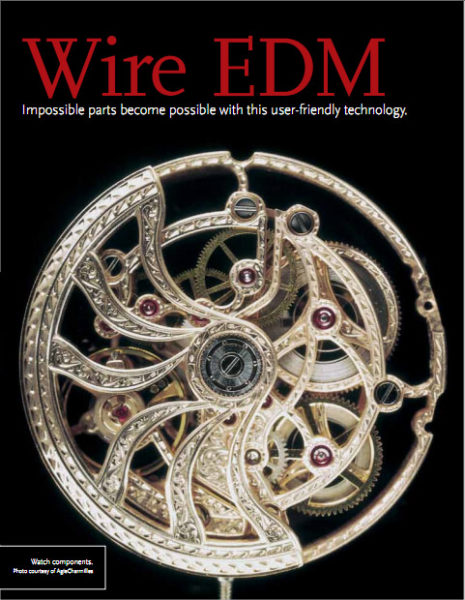

Ideal candidates for wire EDM pose one or more specific challenges—“Small-radius inside corners, tight slots, or difficult-to-machine material, whether hardened parts or a high performance alloy,” said Steve Bond, national sales manager, EDM group, Methods Machine Tools, Inc., Sudbury, Mass. “Sometimes you’ll have a part that absolutely can’t have any burrs on it, or you may want a superior surface finish, said Greg Langenhorst, technical marketing manager at MC Machinery Systems, Inc., Wood Dale, Ill., distributor of Mitsubishi EDM machines. “Some machines can produce fine surfaces—2.5 to 3 micro-inches [RMS].”

Wire EDM is moving into applications that were previously broached, said Bond, such as the “fir tree” slots, where turbine blades attach to the hub for power generating applications.

Subcontracting wire EDM

You may already send parts out to shops that specialize in wire EDM work. “Most of our work is subcontracting—commercial, aerospace, medical, tooling, anything that uses a machine shop,” said Richard DeRosa, production manager at EDM Xpress, Inc., Placentia, Cal. “If a shop can machine a part, they do that. EDM is often the finishing touch. If a customer designs a part with one last cut they can’t get to, we’ll EDM it.”

An experienced EDM shop can help you do what needs to be done, even seemingly impossible parts, DeRosa said. “A customer may say, ‘I need it made, but I don’t know how it’s going to be made.’” Sometimes DeRosa works with an engineer and says, “It will be cheaper if you do it like this,” changing features that are hard to achieve. “You can make slight changes and save money.”

Bringing wire EDM in house

Most shops that spend $30,000 to $40,000 annually jobbing out wire EDM work can justify getting their own machine, said MC Machinery System’s Langenhorst.

When shop management discovers it costs only five or six dollars an hour to run wire EDM, they often quit outsourcing, said MC Machinery System’s Bond.

They may get an EDM machine for one particular project—an inside corner they couldn’t cut, or parts in a high-nickel alloy. The new EDM machine might be running only one-third of the time, Bond said, and then someone realizes it could run overnight for $25 or $50 and get a part made. You can load up the EDM machine’s table with a punch and die set on one side and a carbide piece on the other and run it unattended all night, he said.

Your own wire for higher quality, predictable scheduling

A shop that does its own wire EDM can control the process, said Bond. “If you have the machine in house, you can take more passes to get a better finish or higher precision. Sometimes you have the opportunity to make products for a customer better than you’ve delivered in the past. For example, a punch or die that will last longer.” With in-house wire EDM you can get control of scheduling and don’t have to deal with the EDM shop’s lead time, so you can quote shorter delivery times.

Wire EDM opens up possibilities

“Whatever you think you can use wire EDM for, there’s much more,” Bond said.

One shop bought a wire EDM machine because they needed to cut tubes with no burrs, said Gilbert Levin, business development manager at Ague Charmless LLC, Lincolnshire, Ill. As soon as employees returned from the training class they were sending emails with “Can we do this? Can we do that?” It opened up the engineering department’s mind to do different things, he said. For example, a tool and die shop buys a wire EDM machine to make punches and dies, and then they see they can cut pressure pads and strippers, too, said Langenhorst. Another shop designed its own tool holders for turning tools and produced them on wire EDM machines.

Today’s wire EDM machines are expert systems, said Levin. The machine makes the rough cut and skim cuts—one, two, three. It even knows to slow down in the corners. All this know-how is in the machine. You can come back six months later, put in the same program, and get the same part. If you want a very reliable and automatable process, wire EDM is perfect, Levin said. “It may be slower than [conventional] machining, but who cares as long as you can run it over the weekend?”

The wire EDM process is clean, there are no expensive end mills to wear out, and you always have a fresh cutting tool. Also, Bond pointed out, “There is no fire hazard—it’s done under water.”

Wire EDM means a different way of doing things. It requires a change in perspective—you have to think of wire and water instead of feeds and speeds—but it can make cuts not possible on a machining center. Adding wire to your repertoire can increase your capabilities and help improve your competitiveness in today’s challenging markets.