Today’s Machining World Archives February 2008 Volume 04 Issue 02

Dear Shop Doc,

Dear Shop Doc. I’m milling a slot along the length of the part on .875 aluminum hex parts with a Mitsubishi M635 controlled Citizen-Cincom C32. In the process, my hex stock sometimes has a large twist in the bar, resulting in up to 8 degrees of rotational error from the hex fat to the milled slot. What can I do to get rid of this error?

Twist and Shout

Dear Twist,

All of the Mitsubishi M635/M700 con-trolled Citizen-Cincom machines come standard with a torque sensing feature “G160” that can be used for many interesting applications such as yours. We helped a customer a while back with the exact same problem as yours. The following is what we did.

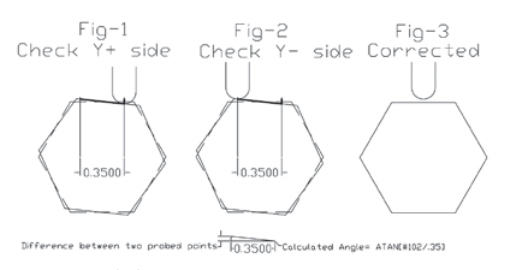

To be quick and simple for the customer, we installed a .187 ball nose end mill in an unused live tooling station. We then programmed the tool as a probe and touched it to one side of the hex; recording the position it touched (Fig-1). We then touched the other side of the hex the same way (Fig-2). With two points known, we did a macro calculation to figure the amount of error (Fig-3), and then positioned the C axis to that value. This process only added about 3 seconds to the cycle time.

See the program example below…

M5

T800(BALL-MILL-USED-AS-PIN)

M18C0 (C axis to zero)

G50W-.5905

G98G0X1.3Z2.T8

Y.35(a Y position good for checking)

G0X1.

G160Q30.X.7F10.(check Y+ side When X axis reached 30% of load stop)

#100=#5041 (record the X value on the Y+ side)

G0X1.

IF[#5041GT.75]GOTO10

#3000=1(—ERROR -CHECK PART ROTATION)

N10(CHECK-2ND-SIDE)

Y-.35(same as above but negative)

G0X1.

G160Q30.X.7F10.(check Y- side When X axis reached 30% of load stop)

#101=#5041 (record the X value on the Y- side)

G0X1.

IF[#5041GT.75]GOTO20

#3000=1(—ERROR -CHECK PART ROTATION IS TOO BIG)

N20(DO-CALC)

#102=[#100-#101]/2

#103=ATAN[#102/.35](Find the rotation error)

G0H-#103 (re-position the C axis incrementally)

G0X1.3T0

G50W.5906

Here are a few other applications you can use the “G160” for:

- To check if a cross drill or face drill was broken.

- To find the location of special extruded stock with a special multi-shaped ID.

- Often it’s used to check the collet pressure on the main- or sub-spindle to confirm clamping pressure before heavy drilling/turning.

- You can even use it for in-process gauging to set and check offsets while running.

Good luck with your problem. If you can follow these instructions these twisting problems should get under control.

Brian Such

Marubeni Citizen-Cincom Inc.,

Cust. Support Group Manager www.marucit.com