By Noah Graff

Today’s Machining World Archives April 2009 Volume 5 Issue 04

February 16-28, 2009, I traveled to Japan; with business class plane fare and three days of accommodations and activities generously paid for by Japanese machine tool builder, Mitsui Seiki. I was part of a group of 15 people, comprised of the company’s sales managers, salesmen, distributors, prospective customers and one other journalist from Aerospace Manufacturing and Design. Scott Walker, President of the American division for Mitsui Seiki and organizer of the trip, explained to me that the purpose of the trip was to foster relationships between the company’s brass and prospective customers, which would hopefully lead to selling some machines. It made sense—do some fun activities, bond, network—but I still didn’t fully understand the overall significance of bringing everyone across the globe until after the company’s program ended and I traveled around the country on my own for a week.

At 5:00 a.m. on the first morning, Scott took us to Tokyo’s Tsukiji fish market. It’s the world’s largest fish market and a beautiful, raw demonstration of capitalism, where giant fish are auctioned off for the equivalent of tens or even hundreds of thousands of dollars. It’s not a tourist attraction— and if you don’t watch your back the fish vendors can run you over with their motorized carts. We walked it, smelled it, photographed it (we weren’t supposed to), and breakfasted at one of Scott’s favorite ramen noodle stands.

A few hours later the group was bused out of Tokyo to Mitsui Seiki’s headquarters where we received a tour of the facility and a presentation from Scott demonstrating the extreme accuracy of Mitsui Seiki machines and the company’s distinct business model. He emphasized that what sets Mitsui Seiki apart from other machine tool builders is that every one of its machines is made to fit the customer’s specs—every component is produced in-house and the ways are all hand scraped. The company only produces 25 machines per month, lately focusing on 5-axis horizontal and vertical machining centers. Its main market is aerospace, which utilizes the machines’ capability to reach an accuracy of 20 microns.

As I expected, the plant was quite clean. The tables were laid out in a way that clearly pointed to the impressive precision of the ways. I’ve had tours at some impressive machine tool builder plants before—Haas in California, ZPS in Czech Republic, to name a few, but it took my 11 days in the country to understand how Mitsui Seiki builds its machines and runs its company in its own “Japanese way.” What first comes to mind is a parallel between Mitsui Seiki machines and Japanese cuisine. I see a Mitsui Seiki machine like a piece of sashimi sushi. Sushi, as with most Japanese food, is delicately prepared, and presented with the utmost of care. The knives used to prepare sushi are as sharp as possible so each piece of fish can be sliced with the greatest precision possible. The quality of the fish is also essential—if the fish isn’t truly fresh it has an inferior taste. Sushi is often quite expensive and if improperly cut could even cause death, in the case of fugu (blowfish).

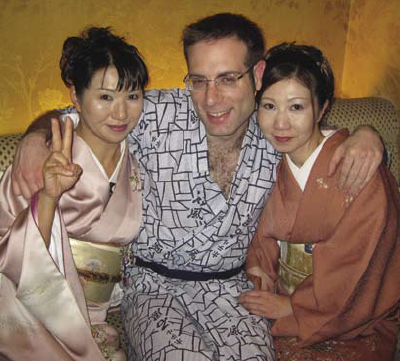

Seventy five percent of Mitsui Seiki’s products stay in Japan. But still, the company knew it was important for us “gaijin,” or foreigners, to experience the culture that produces the machines to really understand how Japanese products are unique. The longer I remained in Japan, the more I realized that in Japanese culture, presentation is vital to demonstrate a product’s quality, a company’s quality and a person’s quality. After we visited the company’s plant we were taken to a traditional Japanese hotel called an “onsen,” where we all were required to change into kimonos. We sat on the floor for a traditional Japanese meal of several courses served on individual trays. Numerous small dishes were meticulously arranged on the trays, and contained various raw fish, tempura, pickled vegetables and strips of beef that were cooked in front of us. While we ate, four geishas poured us sake, played instruments, danced and joked with us, putting cheesy, feminine wigs on our heads. We were entertained in a centuries old tradition by women whose lives’ work was, again, devoted to presentation. After the Mitsui Seiki tour ended and I traveled to Kyoto, my fellow hostel dwellers were envious of my geisha experience.

Most of them hadn’t had the opportunity to even see a geisha, let alone be entertained by four of them. There are only a few thousand geishas left in Japan, and their services cost thousands of dollars. But I’m pretty sure that the expense of the geishas wasn’t even debated when Mitsui Seiki planned the trip. It came down to presentation once again. I believe the company hired the geishas because it was the Japanese way. It was the same reason they flew us all business class. They didn’t have to. I would have fl own crumpled in coach in a heartbeat, but business class was the civilized way to travel. It was the proper way to represent the company.

Still, it took me several days after the night with the geishas to identify Japan’s obsession with presentation. It finally hit me when I bought one small cookie at a train station in Tokyo. In 30 seconds, the vendor quickly inserted the cookie into its own individual plastic sleeve, sealed it and then placed the sealed cookie into a larger paper bag. To finish the experience, the vendor presented me the cookie followed by the receipt with two hands carefully balancing the items as though she were presenting me a sacred samurai sword. It was a true Japanese experience. Thirty seconds later it was a real pain to open the packaging, and the excessive paper was terrible for the environment. But this was Japan, and I was starting to get it.

In the Mind of a Japanese Business Man

One of the top journalistic priorities for my trip to Japan was to interview a “quote-un-quote” Japanese businessman. It’s an archetype you see in movies—the small Japanese guys walking around in black suits, riding the busy subway to go to work at large corporations. The trip’s organizers, Lynn Gorman and Scott Walker, warned me that finding someone willing to be interviewed wouldn’t be easy because it might be construed as singling out one person as more important than his peers, which is taboo in Japanese culture. Fortunately, Roy Kawakami, senior general manager of corporate finance and accounting in overseas operations for Mitsui Seiki and close colleague of Scott Walker, casually agreed at dinner the night I arrived to let me interview him. Mr. Kawakami turned out to be a great source for perspective on the differences between Japanese and American business culture. He had received his CPA in the U.S., and he spends two weeks a month in the States working for the company.

Roy explained that one of the fundamental differences in the philosophy of American companies and Japanese companies is that U.S. companies focus on the contributions of individuals, while Japanese companies value the performance of groups or teams. In the U.S. if an employee performs poorly he can be fired, but in the Japanese business model the group manager is held responsible for an employee who is not performing well. This custom is coupled with a traditional Japanese business practice which grants lifetime employment. Thus workers must be motivated in different ways than in the U.S.

Another difference Roy brought up is that unlike most American companies, Japanese companies don’t base their business systems entirely on the goal of meeting monetary targets. He said that in the U.S., companies systematically try to reduce manpower, calling it a “direct approach to results-meaning cutting costs,” while the Japanese emphasize and pay more money for processes. He said he thinks that the philosophies of Japanese businesses are gravitating a little bit towards those of the U.S., but he reiterated that traditional culture is still very important in Japan, which means taking care of customers and giving great service. “Even the McDonalds atmosphere is different,” he said.

It was a great interview—for me at least. But I could sense that Roy wasn’t feeling great about it. He told me afterward that he was little embarrassed about doing the interview. I then felt uncomfortable because I knew Roy was stressed out. I was also undergoing a bit of culture shock. It bothered me a little when Roy didn’t look me in the eye during the interview, likely because eye contact can be seen as aggressive in Japanese culture. I was also bothered by what he had told me about the Japanese view of individualism. It was counter intuitive to the way I approach life. I’m paid to think as an individual, to write about new ideas, to make people think. Suddenly it clicked—I was truly in a new culture, but not surprisingly, I was learning as much about myself as I was about Japan.