Assorted thoughts while waiting for the Sweet 16 to unfold.

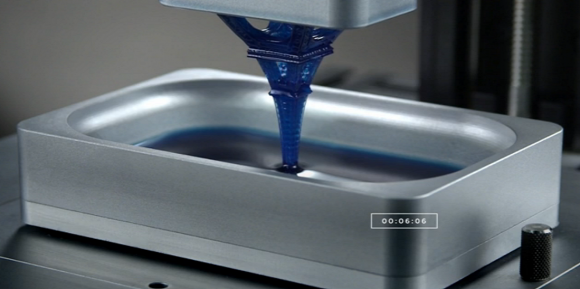

In our business world, 3D printing is the technology the lathe and mill guys pooh-pooh, but we should not be so complacent. The latest refinement substitutes layer by layer printing with a liquidy glop that is potentially much faster. The day is coming when shops will have both additive and machining technologies available and will offer the best option to a client. This will also be a tremendous marketing approach – offering both.

******

I wish I’ve seen a team that could beat Kentucky in the first two rounds, but I have not. I’m rooting for Wisconsin, but they do not have enough athleticism to beat the Caliparians. Kentucky’s depth and brute athleticism trumps Duke’s fabulous shooting. Gonzaga just isn’t quite good enough either in the front court or backcourt. Michigan State is peaking and probably makes the Final Four, but they do not shoot well enough to beat Kentucky. What people do not realize about Kentucky is that they play well together and they are young, but not that young. The Harrison twins are sophomores and play with maturity and total confidence. Willie Cawley-Stein is an upperclassman who plays with wild animal ferocity. He scares me – even on TV. I wish I could say it ain’t so, but Kentucky in a walk.

******

The data shows that American business is not investing in heavy duty capital equipment with a 15 year or more usable life. On the face of it this sounds like very disturbing news in the machining world, but I think we need to understand this statistic in context. Consider electric utilities. Utility companies used to build new plants every year or two. Same with oil refineries. Competition and environmental hounding have forced companies to get more efficient rather than build more plants and add more turbines.

Think about how you can produce more with less today. Capital gravitates to where it is more productive. Monster factories are rare today. If battery technology progresses the way Elon Musk and others think it will, we will be moth-balling oil refineries and traditional electric generating facilities, not building more.

******

March 24 was the day the Iran nuclear talks were supposed to end. I expect they will grind on as the Persians continue to play the Obama administration for the fool. If there is a deal, it is highly unlikely to be ratified by Congress. For Iran, it’s heads we win, tails we win. The Saudis and the shale drillers are playing the best card against the Ayatollahs by depressing crude oil prices.

******

I applaud Howard Schultz, Chairman of Starbucks, for attempting to initiate discussions about race relations in his cafes. The Starbucks I frequent in Homewood, Illinois, has 60-40 black to white clientele. Through the years I have made black friends there and had many great conversations with people who have darker skin than mine. I have written about struggling with my own racism in other columns, but I have used Starbucks as a safe haven for talking race. Starbucks is America’s meeting place. Thank you, Mr. Schultz.

Questions:

Do you think you will use 3D printing in your shop anytime soon?

Who do you like in the NCAA Tournament?

15 Comments

We have a couple of 3D printers humming along right now for learning purposes. Trying to understand the limitations. We’re just making things like edge guards and cable clips and things like that to build the skills before we jump into more serious equipment.

I wouldn’t turn a blind eye to additive manufacturing. Look at the developments in machining over the last 30 years. Technology turns ever faster, additive is going to be common in a hurry.

Go Bucky! My head says Kentucky. My Badgers have a shot, though. I expect them to face off in the championship game. I expect a tight game. Here’s hoping Wisconsin has one of those big games and pulls it off. I’d love to see Bo Ryan get a title at this level.

Wisco can not meet KY in the champ. game, it would be the game to get to the Monday championship. I also root wisky, but KY too strong.

One piece of basketball many people over look. Basketball is a game if possession. If you have the ball you can score. If you don’t keep possession then you give up your chance to score. I will only say if you look at the UW Badgers saying they are stingy with possession you are right. They play the game without out Fast pace, or fancy dribble drive. They approach each possession the same. Same idea each time take a good open look shot or move the ball to someone who has a better choice than yours.

I see the games that come up now as exciting games to watch and most of how those games will be played by the UW Badgers. As the tournament goes deeper it becomes more of a coaches duel as the talent becomes less mismatched. The UW Badgers have very disciplined players at all positions and at all spots on the depth charts. I wouldn’t want to have to try and out coach Bo Ryan either. It will be fun to see how it ends up. My pick is Bucky all the way!

“Think about how you can produce more with less today” That’s good and bad. I only need half the guys to do the same work. So that’s 5 less people working.

Will I use a 3D printer. I don’t know, can they print 60 Rockwell parts.

NCAA – I like Wisconsin. Not saying they go all the way though.

Check out NanoSteel’s new 3D printing powders. 1000 Vickers hardness.

I did not know that, interesting. Wonder what kind of tensile strength can be achieved. hmmm

We are currently using 3D printing with ABS plastic to make some of our tooling components to hold our parts for certain operations. These are nesting type fixtures that are not precise or in operations that generate heat. This has worked very well for us. The cost and turn around time on the plastic tooling is much better than the previous metal components. Our next step will be to glue or heat sink metal components to the plastic for precision and durability. It is an exciting new technology that opens your imagination but the materials have limitations.

Don’t count out MSU!

Go Green!

My son is an aeronautical engineer and while in college and since has constructed 3D printers out of OTC components for a reasonable price, under $1000 for a complete printer. There is an open source online community that is an excellent source for home built 3D printer design and components called RepRap. These home built units rival the quality of printed parts from additive printers costing thousands more by 3D printer companies. Once there is a break through in 3D metal materials manufacturing, milling will become a secondary operation for highly detailed parts.

how about hybrid additive/subtractive manufacturing!?! http://us.dmgmori.com/products/lasertec/lasertec-additivemanufacturing/lasertec-65-3d

We have a 3D printer we use for making design review sales models. We also use it to make parts to use for programming our CMM. We are looking at 3D metal printers – several competing technologies, different properties, all very expensive. The technology is not quite there yet for general use. Good for impossible geometries. Why is everyone thinking that additive manufacturing is new? Casting and powder metallurgy are also additive manufacturing technologies. 3D printing is new, additive manufacturing isn’t.

Good point!

If you need really tight tolerances you still have to machine 3D printed parts. And engineers are increasingly tightening tolerances – not opening them up.

I have always thought of 3D printing as near-net shape and not as final net shape. Sure there are some parts with tolerances wide open enough to print net shape but rarely will every dimension and feature be that wide open. In that respect 3D is more of a partner to machining not competition. Embrace it.

We use 3D printers all the time for prototyping. While they aren’t quite cost effective to be production ready, they are definitely essential in an R&D type setting. In this setting they actually do save cost and time. As they catch on they will percolate throughout the rest of the market and eventually make their way into machine shops for production since they have capabilities that you can’t replicate with injection molding or the like.