I love to watch the Shark Tank reruns on CNBC. The stories of committed entrepreneurs putting it all on the line in orchestrated mini-dramas in front of the “Sharks” is really quite absorbing.

But the one thing I never see on the program is the entrepreneurial manufacturer looking for the backing to buy a Haas Mini Mill or Okuma lathe to start his business. In our machinery business we virtually never see a young man or woman buying a used machine to make fittings for Parker Hannifin or John Deere.

I asked Bryan Harvey of Thompson Auctioneers if he sees many young entrepreneurs buying their first machines at his sales and he said it is “extremely rare” except perhaps for the folks in Bangkok or Bangalore, India, who follow their sales assiduously on BidSpotter.

Is the fledgling entrepreneur in manufacturing now an artifact in America? Maybe not.

I called Matt Hertel who started Pocket NC, a $4,000 5-axis CNC mill builder in Bozeman, Montana, and he gave me a different picture.

Matt and his wife, Michelle, started production on the machine in 2015 after moving back to Bozeman from Seattle. They raised their startup money not on Shark Tank, but through the novel Kickstarter approach online. They had already built several prototypes of the mill, and Michelle had blogged extensively about the market and buildability of a $4,000 5-axis mill to prepare a community for the ultimate Kickstarter campaign.

The Hertel’s had tried conventional money raising forays, doing a dog and pony show on video for the private equity titan Blackstone Group. He was told that it was probably the worst received pitch of the year.

But Kickstarter loved them. They raised $350,000, which was to be paid off in product produced. Each $4,000 contributor to Kickstarter was repaid with a 5-axis mill.

Matt Hertel told me that the most successful Kickstarter event of all time may have been for potato salad. An entrepreneur with a $10 minimum contribution raised $70,000, which he paid off in a giant potato salad bash.

In its first three years in business Pocket NC has been quite successful and has sold little mills to a wide assortment of bigger companies and tiny startups. One just went to Europe to a guy who is making a bicycle washing machine.

I posed my question about an apparent dearth of machining startups to Matt, and his feeling was that I was looking in all the wrong places.

Matt believes the entrepreneurial spirit is alive and well, even in the Millennial world, but you need a community, whether it be online via Kickstarter or in coffee shops or incubators in Bozeman. Matt says that in his Montana home there is a community of folks eager to help anybody with an idea and the guts and skill to try to bring it to fruition. You cannot create a milieu like that artificially with government funding and Big Brother hovering. A grant from Google or IBM to jumpstart an incubator in Chicago or Cleveland unfortunately will not work. The community needs to grow organically like it has in Bozeman. Could it happen in Detroit or Cincinnati? Maybe, but I do not see it happening yet. But with precision manufacturing as strong as it is today we may begin to see it. As the Baby Boomers hang it up and old businesses dissolve, there will be opportunities for startups where we have not seen any for the last decade.

If potato salad can do it …

Question: Is it a good time to start a business in the United States?

5 Comments

Any time is a good time if you are motivated and are willing to make the sacrifices required. The spectacle of governments tripping all over each other to attract Foxconn or Amazon is silly when just a bit of encouragement could be empowering the next big thing.

If you have a good idea,it is almost always a good time to do a startup.Start small,build up a modest profit and use home and family generated cash and regular bank sources for your funding.Don’t waste valuable time pitching people.

Who knows better than you what you need and how to build your product?.Other business associates can help you design marketing approaches and you can keep control.Advice sometimes is bad and often good but it is FREE.Listen,learn and keep making product.Dont wait for outside help.

If you aspire to be a mom and pop operation go ahead and get it started. Doing piece work will be worthwhile. Customers like Parker or any of the auto companies will not even talk to you. When the baby boomers founded their businesses connections helped forge the way. In today’s world you not only need the connections but the backing of one of these large companies. Not going to happen.

Lloyd,

I agree you’re not looking at the right places. If you ever want to get a overload dose of innovation, you need to go the Midwest Reprap show (MRRF) in Goshen Indiana. It’s hosted by a company called SeeMeCNC. Great folks who make great product.

I remember talking to Sanjay the owner of E3d at MRRF. He’s a young British man who start making hotends for his 3d printer. He started out literally with a lathe in his bedroom of aparment making 3d printer hotends for people and has grown to a 25 man operation. Josef Prusa from Prusa Labs is also a regular there (He’s basically a rock star of the open source 3d Printer (reprap) community.

MRRF it’s the largest show dedicated to open source 3d printers. It’s grown every year that I’ve attended. What interesting is I’m seeing startups building low cost subtractive CNC’s as well starting to show up there this past year.

I don’t see young entrepreneurs starting out with a Haas or an Okuma… I see them starting out with a Mostly Printed CNC (MPCNC), Shapeoko’s,, Carvey’s. There is a very very rich ecosystem out there. It’s not exactly high precision machining but it thousands of people getting into CNC and are starting out on controller systems like Grbl, LinuxCnc and Machinekit. I see a pool of people learning about CNC who will be wanting more than a machine than cut wood or machine aluminum. I think this will be the pool for the next generation for High precision machining of steel.

Have you ever been out to Tormach in Madison Wisconsin? I think they snag a lot of the business for that next level. They cater to the entrepreneur, makers and research labs. They are experiencing exponential growth and are widening out there product line. Their equipment is for light industrial grade and not as durable as Haas or Okuma for hard production use, but it’s affordable for a startup and backs plenty of bang for the buck till they’re ready to the big league. They are incredibly nice people as well with a expanding product line.

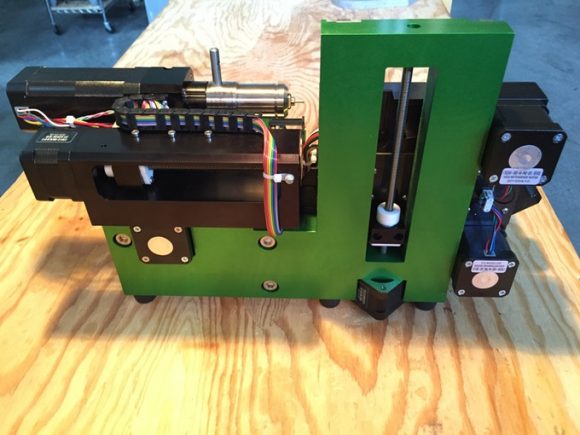

I think the PocketCnc (which uses Machinekit as it’s controller) is a very cool machine. I’ve seen one at the the MRRF and hopefully their will be a MKII version there next year to check out.

You need to visit maker spaces such as Maker-Works in Ann Arbor, or Tech Shop in Dearborn (both outside Detroit), I3 Detroit, and other art and creative spaces such as Fortress Studios (also Detroit). The entrepreneurial spirit is indeed alive and well, and is in fact feeding industry. There have been several companies get their starts in Maker-Works Ann Arbor, it is a great incubator. Two off the top of my head are http://sightmachine.com and Pico Spray (https://www.crunchbase.com/organization/picospray#/entity). These “maker” organizations DO buy used (and new) machinery and so while a budding business builders may not buy machines themselves they are joining these organizations to have access to way more machinery than they could afford on their own in order to start their venture. The other resource a member of these organizations gets is comradery, advice, and help from other like mind innovative makers. This is an oft under appreciated aspect of these places.

I also think that as time goes on, and our realization of how poor a job we have been doing to train our kids for non 4 year college career tracks leads to continuing improvements in that area, you WILL begin to see folks looking for funding for machines and manufacturing related businesses. Time will tell on that front…