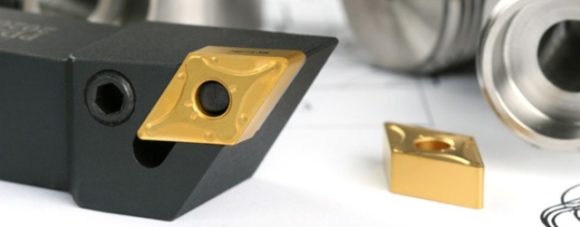

This basic truth haunted Brian Nowicki for years as he moved through important jobs in the distribution of tooling and machine tools for 30 years. The opportunity he saw was in the dead inventory sitting in the Lista and Vidmar cabinets all over the world, filled with perfectly usable cutting tools that were no longer needed by manufacturers or couldn’t be sold by the Sandviks, Iscars and Kennametals because they had developed slightly more advanced cutting materials to push.

This basic truth haunted Brian Nowicki for years as he moved through important jobs in the distribution of tooling and machine tools for 30 years. The opportunity he saw was in the dead inventory sitting in the Lista and Vidmar cabinets all over the world, filled with perfectly usable cutting tools that were no longer needed by manufacturers or couldn’t be sold by the Sandviks, Iscars and Kennametals because they had developed slightly more advanced cutting materials to push.

Tooling Marketplace is Nowicki’s online answer to the problem of unloved inventory. It is an Internet supermarket of carbide and other cutting concoctions artfully displayed and organized so buyers can buy new surplus cutting tools for a fraction of the price they would pay for the current favorites of the industry. Nowicki and his partners knew that “last year’s model” did not mean “no good,” just “unloved.” If he could get the cutting tool manufacturers to buy into his concept of unloading yesterday’s best idea in tooling on his site, he had a business.

He and his partners were veterans of the cutting tool industry. They had contacts all over the world of chip-making. They wanted to build a site that would be focused on just one piece of the metalworking world. It would have some of the elements of an eBay, but it would not be a hodgepodge of goods. It would have some of the best of a Grainger or MSC, but it’s strength would be its depth and familiarity with the primary industry it was serving.

Tooling Marketplace just launched in August and the early indicators are positive. Manufacturers like Kennametal and Ingersoll have embraced the idea and put over $3 million worth of inventory on the site. Nowicki expects to double that amount in the next few months.

Now his biggest challenge is to attract the buyers. He makes money when the goods actually move out of the bins. Tooling Marketplace gets a 12% commission from the sellers and an 8% handling fee from the buyers. Transactions are all online. Tooling Marketplace is sending out targeted email blasts to advertise special deals. They need to get traction fairly quickly to make their site a legitimate habit-forming Internet location for both the everyday and the exotic in cutting elements. They invested $100,000 in the software to make the idea into a business. They are hoping distributors of tooling will be both buyers and sellers on Tooling Marketplace and will attract end users who will invest the time to browse last year’s model of boring or drilling carbide to save some cash. On many jobs the difference between 41-25 and 42-25 carbide on the shop floor is infinitesimal.

The big test for the site is to be able to attract viable new inventory to keep buyers interested. The inventory will come if they can get the word out to the buyers and get them to try it — the usual chicken and egg problem in the distribution world. I wish them luck — and lots of carbide.

Question: It is it worth spending a lot of time looking for bargains while running a business?

5 Comments

Good luck with this endeavor I am sure there is money to be made and saved on out of season carbide inserts. You can also have Knight Carbide make inserts for out of season tool holders that aren’t supported anymore. They don’t go bad either.

On occasion I look for obsolete (but good) carbide. Usually on Ebay. I like the idea of somewhere else to search.

My experience with selling technical carbide tooling over the years leads me to believe that the larger metalworking customers won’t participate due to the unpredictability of specific inserts availability. Their machining centers are dialed in to the tooling that maximizes their programing. However, I am impressed that you have the participation of so many quality manufacturers. The middle to small market user is probably a great target for this service. Some will be willing to change their speeds and feeds to accommodate differing geometries and grades. Reaching them and making their purchases extremely easy will be the real challenge. You better have a supercharged SEO program to have a chance for success.

Also would be a great resource for trade and technical school training programs. Industry uses carbide for most applications, but local schools here are using HSS tooling. This might offer them a chance to get carbide at a more competitive price.

That site would have helped when we were running the old manual Bullard VTL’s.

Was always looking for deals on inserts.

Do check out eBay once in awhile. Found some very good deals on new milling cutters.