Terry Iverson is a lifer in the machining industry. His grandfather sold machines for Hardinge over 100 years ago, and for 40 years he ran the Hardinge machinery distributor for the Midwest.

Today Terry focuses his efforts on getting young people in America into manufacturing. He wrote two books directed at parents to open their eyes to manufacturing careers for their children.

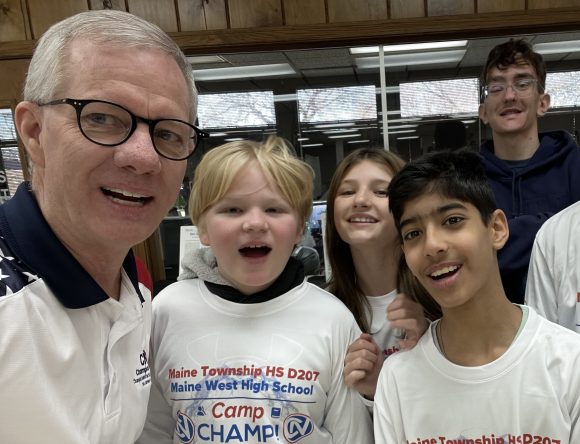

His latest project is a machining camp called Camp CHAMP, in which middle school kids are mentored by high school kids running CNC machines.

Even though Terry is 20 years older than me, I feel like we really connect we talk. We’re both third generations in a family machine tool business. We’re both creatives, and we both love to reflect on serendipity in our lives.

*************

Listen on your favorite podcast app using pod.link.

View the podcast at the bottom of this post or on our YouTube Channel.

Facebook: https://www.facebook.com/swarfcast

Instagram: https://www.instagram.com/swarfcast/

LinkedIn: https://www.linkedin.com/company/todays-machining-world

Twitter: https://twitter.com/tmwswarfblog

*************

Link to Graff-Pinkert’s Acquisitions and Sales promotion!

*************

Main Points

Choosing a Trade in United States Vs. Europe

Terry Iverson: In Switzerland and Germany, they ask young people early in life to figure out what they’re passionate and skilled at doing. At like 14, 15 years old.

Noah Graff: How does a 14 or 15 year old know what they’re meant to do?

Terry: Sometimes they do. In this country, internships are the answer. I write a lot about that because you don’t know what you’re passionate about or what you’re even good at unless you try it. It’s awesome if you could get an internship when you’re a teenager, that’s life-changing.

And if someone gets an internship in something and they say, “I hate this,” that’s not a bad thing. You just saved yourself potentially four years of college studying something that you should never study.

Noah: I think one of the great things about the United States is that we’re into trying different things.

Terry: There’s no question. But I think the biggest takeaway is that we need to spend more time empowering our young people, our children. What are they really good at? What are they skilled at? What are they passionate about? And allowing them the freedom to pursue something that they’ll spend a lot of time doing and presumably enjoy and do very well.

Camp CHAMP

Noah: Tell me how the CNC Machining Camp came about?

Terry: I did a camp. I actually picked up and shipped a CNC machine down to Florida at my expense. I set it up, programmed it, took an optical inspection system down with me, took a week off work and spent time with 10 high school young people and taught them about manufacturing.

What I realized is, not including the hard costs, just the cost of the machine tools, it was 10 grand.

What it taught me is that this was not a sustainable role or path in terms of introducing manufacturing to young people.

So I decided to buy a couple custom-made tabletop CNC machines and have them programmed, and we set up making pens. The lathe turns the top and bottom segment of the pen. And then the mill, we take pieces of wood and mill out, almost like a router, the wood for a top and bottom case for the pen.

Then I came up with a concept to take these out into the field to inspire middle school students. It’s not educational because it’s not broad enough to be educational. It’s more inspirational and informative, introductory. IMEC, the MEP for Illinois, decided to give me a little bit of money to do five camps. We ended up doing six over about a six-month period. A camp is defined as a morning session and an afternoon.

We have six different stations: lathe, mill, CNC control, laser engraver, assembly station, inspection station, and a programmable rotary station. What we do is every 15 minutes, we take 24 young people, divide them into six groups, so there’s only four per group, and then we have a mentoring component. We have a high school CTE student mentor the middle school students.

The middle school students become the mentors later for the next group of middle school students. And the host can either be a technical college or an industry member. So you have a path from middle school to high school to technical college to industry. It’s a total path.

We did the first six camps, and now IMEC has come to me again and said to keep doing this, they’re going to fund us again.

One thing I left out is that out of every 24 young people that come, only one or two know anything about manufacturing. We ask them when they first arrive. At the end, you can tell just by the excitement that you see and what they’re learning. They go home with a pen with their name laser engraved on it, and they get a shirt with their school name and cool logos.

There’s at least 10 that go home all excited about manufacturing. It plants a seed.

A Serendipitous Moment

Terry: I was having a tough time being the only sibling in our family to work at the company.

I went to a class at Harvard for a week. It was a strategic finance class.

I was really struggling, and I met a woman from Brazil that literally kind of said, “Get over yourself.” And I’m like, “What? I don’t even know you. What are you talking about?” She’s like,

“Going into your family business and being the chosen one to take it into the future is an honor, don’t you know? You were chosen for a reason and you should be privileged and honored that you were chosen. Quit whining and get over yourself. Just accept your destiny and just do it. Do what you’ve been destined to do.”

I was just so taken aback by her candor and her frankness. I was just like, “Well, obviously I needed that.”

Noah: And you were in the right mindset to receive it.

Terry: I’m always open. That’s why it happened.

Podcast: Play in new window | Download

1 Comment

You need projects to take kids eyes off of their cell-phones and video games. Heck, this even applies to adults. I’ve never seen so many people walking outdoors for exercise with their eyes glued to their cell-phones.

Kids need to be drawn not only to manufacturing, but STEM disciplines (Science, Technology, Engineering, Math) in general. Competitions such as solar cars in universities and Robot-Wars would attract young adults and kids. Who doesn’t like to see robots fight to the death in an enclosed ring? I’ve watched competitions and it is entertaining & informative. All kinds of manufacturing goes into building robots…materials, CAD/CAM, machining, electrics, electronics, pneumatics, hydraulics etc. Schools should set up competitions. Model-rocketry and radio-controlled models are other avenues that can & should be explored.

Most people haven’t a clue of how goods are produced. They just see the end product sitting in their local store.

Bring back shop classes!