Today’s Machining World Archives November/December 2010 Volume 06 Issue 09

Below are three proposed solutions to October’s “Think Tank” challenge from three gentlemen at Conquest Machine in Las Cruces, N.M. They asked me to send them the answer immediately so their debate over who was correct could be put to rest.

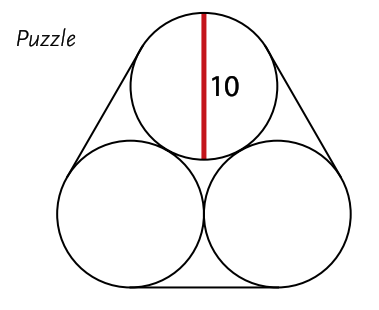

How long is the rubber band?

Correct Answer

The straight lines are 10 cm x 3 cm. All the curves will be exactly the circumference of a circle, which is 2 x 5 x 3.14159 = 31.4159 cm. Thus the total length is 61.4159 cm.

Proposed Answers:

- Michael Blea: 66.27 cm (used CAD program)

- Greg Coker: 64.135 cm (but wants to submit 65.00 cm) (drew actual problem and used a string)

- Lee St. James: Answer 61.416 cm (50-year-old machinist manual and a calculator)

Winner

The 50-year-old machinist manual and a calculator!

A Space Fantasy

I always enjoy your magazine’s wide spectrum of interesting subjects and voyages to places beyond traditional. The article in your October issue, “Manufacturing in Space” by Douglas Graham, is more like a voyage into a fantasyland. The article is an echo from Space Manufacturing 14, a gathering in California a few weeks back of XCOR and NASA PR people and university staffers who acted as snake oil salesmen and believers in miracles.

Shamelessly, the organization that organized this event, Space Studies Institute (SSI), and the presenters rolled truths, half-truths and fantasies into one marketable portfolio in hope of continuing government subsidies. The truth about return on investment from space manufacturing is more like a pipedream that will never materialize. Outer space is not an ideal vacuum chamber but an extremely dangerous area filled with a myriad of solid and gaseous particles and extreme radiation. Forget about manufacturing out there, even continuous biological life similar to that on earth is impossible.

In reality, the whole article is nothing more than a typical Sci-Fi story. It is always important to have life leading targets, especially ones that are chosen for good of humanity. But the shameless sale of empty fantasies for the sake of squeezing money out of the skinny U.S. budget is immoral.

If readers of your magazine would like to find the real history about U.S. space exploration, I would suggest the book by Neil Sheehan, A Fiery Peace in a Cold War.

Val Parker

Parker Design Co.

Pittsford, N.Y.

The True Cost of Wire EDM

I wanted to comment on the “How It Works” article about Wire EDM in the October issue. I have been running wire EDMs since 1976 six to seven days a week. I have owned my own shop since 1983 and have owned and operated 34 different wire EDMs from five different manufacturers in the last 27 years. So I feel somewhat qualified to comment on some of the facts in the article.

On page 21, in the section, “Bringing wire EDM in house,” the author states, “When shop management discovers it costs only $5.00-$6.00 per hour to run wire EDM they often quit outsourcing.”

I have to take exception to that comment because it sounds like it came from a wire EDM salesman. Our machines cost anywhere from $250,000-$300,000 each and our wire costs alone run upwards of $5.00-$8.00 per hour. The author’s source of information, Mr. Bond, neglected to mention the cost of the machine, insurance, rent, salaries, power and consumables like belts, guides, DI resin, etc.

In my opinion these comments severely understate the cost of owning, running and maintaining one of these machines. My current shop rate is anywhere from $75.00-$100.00 per hour. I, hope none of my customers read this piece and misunderstand these misleading comments from Mr. Bond.

Mark Robinson, President

Microform Corporation

Auburn, Wash.