Today’s Machining World Archive: May 2008, Vol. 4, Issue 05

No Cause for Alarm

Fire suppression and machine monitoring can help

protect your machines and your profits

Whether you’re running lights-out, or running with a reduced staff, any time you don’t have an operator right next to a machine paying attention to it, you’re taking a chance that a broken tool or some other mishap will result in a heap of bad parts, damage to the machine, or maybe even setting your facility on fire. Automatic systems designed to keep your machines safe can help you reduce this kind of risk.

As machining centers and other CNC machines get more expensive, it makes more and more sense to invest in fire suppression and machine monitoring systems that may prevent loss and at the same time help you make the most of the equipment in your shop.

No smoking

No one wants to think about a machine catching fire, but sometimes it happens. If an operator is standing by, there’s a chance to stop the machine and hit the fire with an appropriate extinguisher. But if the machine is running unattended, you could lose the machine, or even your whole shop.

A tool breaks, generates a spark, and the oil mist inside the machine ignites. Maybe you’re machining titanium and some thin chips catch fire. By the time the fire and smoke escape the machine enclosure and set off the smoke detectors, the machine may be a total loss. Then, smoke and water damage could shut down your whole shop for quite a while.

Effective, relatively inexpensive fire suppression systems are available for installation into individual machines. These can detect and extinguish a machine fire within seconds.

A fire suppression system for a medium-sized machining center might cost in the neighborhood of $3000 to $4000, installed, said Scott Starr, marketing manager at Firetrace International, LLC, Scottsdale, Ariz. Not a bad price to pay for protecting a machine that can cost hundreds of thousands of dollars.

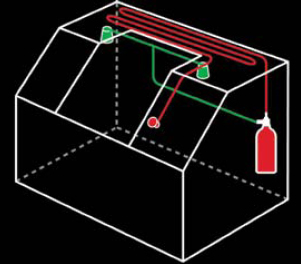

A fire suppression system consists of a detection method and a delivery system for the extinguishing agent. In a Firetrace system, the extinguishing agent is stored under pressure in a cylinder, and is delivered inside the machine enclosure through piping and nozzles.

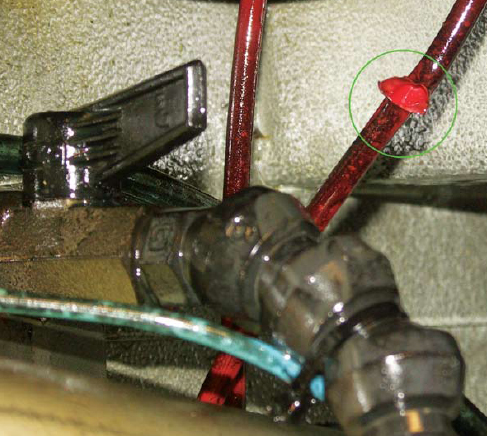

For detection, a Firetrace system uses polymer tubing installed inside the machine where fire may occur. The detection tubing is pressurized with nitrogen. The valve on the cylinder of extinguishing agent is held closed by the pressure in the tubing. When fire is present, the tubing quickly heats up and ruptures. This releases the pressure in the tubing. The valve on the cylinder opens. This allows the extinguishing agent to flow into the machine enclosure.

Your fire suppression vendor will recommend an appropriate extinguishing agent, depending on what is likely to be burning, and how often fires occur. In many cases, oil-based cutting fluid ignites and a “clean agent” can be used. A “clean” extinguishing agent leaves no residue and does not contaminate the cutting fluid. With a clean agent, the machine can be used again as soon as the problem that caused the fire is fixed and the fire suppression system is recharged.

Where a metal such as titanium would likely be the fuel, a suitable powdered extinguishing agent would be needed. The disadvantage of a powder-type agent is that after it extinguishes the fire, you have to clean it out of the machine, and change the powder-contaminated cutting fluid before operating the machine again.

The system includes a pressure switch that actuates when the detection tubing bursts. In a proper installation, the machine control is connected to this pressure switch; when the switch actuates, the control shuts down the machine. It also turns off the mist eliminator which, if left running, would remove the extinguishing agent from inside the machine. If you want, the machine control can also trigger an alarm within the shop, or initiate sending out an alert through a software program or messaging device.

Fire suppression can offer safety and peace of mind when you run lights-out. Even when you’re running machines with operators, many consider it good practice to provide fire suppression on these costly machines.

An ounce of prevention

Fire suppression is key, said Harry Kincaid, president of ATAM Systems, Inc., New Albany, Ohio, a manufacturer of tool/machine-monitoring systems. But wouldn’t it be better to prevent the fire in the first place?

Machine tool monitors can detect a broken tool almost instantly, and shut down the machine before a spark or frictional heating can ignite anything.

“Our systems apply sensors on the machine to measure power, vibration,” and other characteristics of the machining process, said Kincaid. The ATAM unit monitors these signals and initiates an alarm when the measured parameter goes outside signal limits set by the user. If the tool is broken, the result can be a shutdown of the machine. If a tool wears beyond preset limits, the monitor unit can send a signal to the machine control that it’s time to exchange the tool for a fresh one provided in the tool magazine.

In addition to detecting dull or broken tools, a machine monitor can help troubleshoot problems, including lack of coolant during hole drilling or incorrectly fixtured parts. The ATAM systems provide a real-time, live trace of parameters such as spindle power. This enables the user to see ways in which to optimize the machining cycle. The trace makes clear how to minimize the amount of time the tool is cutting air, for example. Also, the machine monitor’s event log can help diagnose problems after they have occured.

Putting principles into practice

Implant Direct LLC manufactures dental implants in the company’s dedicated machine shop, where 26 Star Swiss-type screw machines run around the clock, cranking out thousands of the small, complex, titanium-alloy implants.

The current shop was set up and equipped about three years ago, specifically for running lights-out, said Joe Morales, director of manufacturing at the Calabasas Hills, Calif., company. Each machine is equipped with a fire suppression system, and a machine monitoring system from ATAM Systems, he said.

The day shift is fully staffed, and on the second shift just a few employees tend the 26 machines, Morales said. Then everybody goes home, and the machines are on their own, running lights out for the rest of the night. If a machine shuts down overnight, Morales said, “in the morning we look at the event log on the ATAM [machine monitoring system]” to see what happened.

On alert

If you don’t want to leave a machine idle, you’ll need to be notified when it shuts down.

Machine controls using a Windows operating system with Internet access can use special notification software to contact the responsible staff members by phone, pager, text message or e-mail, and deliver preprogrammed alerts or instructions.

Another alternative is to use an autodialer to make contact. Autodialers are widely used to monitor pumps and other equipment used in municipal water and waste water systems, where public health can depend on quick response to problems at any hour of the day or night.

In the machine shop, an autodialer unit watches the signal from the machine control or machine monitor. When pre-selected events happen, such as a machine stop or a tool going dull, the autodialer makes phone calls to alert the responsible persons.

The Guard-It autodialer from RACO Manufacturing and Engineering Company, Emeryville, Calif., monitors up to four machines, and can call as many as eight phone numbers, delivering a pre-recorded message. The unit calls the numbers in a programmed sequence, and continues calling until one of the recipients acknowledges the message, said Gene Cottom, RACO western region sales manager. You can also call the Guard-It unit from any phone to receive a status report on the machines connected to it.

If you want to be able to watch what’s going on in the shop from a computer anywhere, you can use a Web-based application such as RACO’s AlarmAgent.com service. An AlarmAgent.com wireless remote terminal unit collects data from the machine control or monitor and communicates the data wirelessly to the AlarmAgent.com portal. To see the data, you can log on to your secure account at www.AlarmAgent.com. When an alarm occurs, AlarmAgent.com can notify responsible parties by pre-programmed voice messages to cell or landline phones, alphanumeric paging, e-mail or cell phone text messages.

Attention, shoppers

If there is someone in the shop watching a lot of machines, you may want to provide a local visual or audible alarm that alerts the operator to a machine in trouble.

Many shops use multi-colored signal tower lights – green for OK, red for stopped – which can blink or have a rotating mirror effect to draw attention to a stopped condition. A quick look at a row of machines reveals which, if any, needs attention.

Some say there’s not much point to an audible alarm in a noisy, working shop, but there are self-adjusting alarms that sense the ambient sound and make themselves heard by producing a tone or siren several decibels louder than the background noise level.

Whether you’re running lights-out with minimal staff, or with a full complement of operators, think about what it might cost you in repairs and lost production if a broken tool, a crash or a fire takes down a machine. You may find it makes economic sense to set up automatic monitoring and fire suppression on your machines to protect them, and protect your bottom line.