Today’s Machining World Archive: February 2006, Vol. 2, issue 2

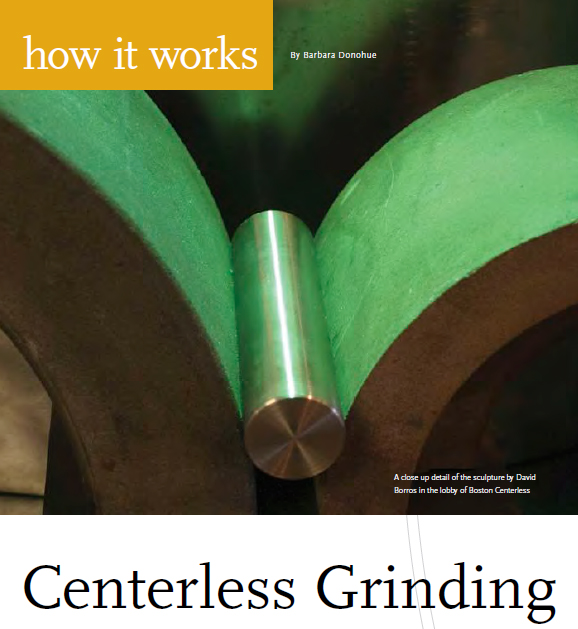

It seems everything is round at Boston Centerless, a provider of ground stock and grinding services in Woburn, MA. The radius on the front corner of the building gleams metallic in the morning sun. A disk-shaped roof supported by cylindrical columns shelters the main entrance. The lobby features curved walls and a circular reception desk. An alcove in the wall displays a metal sculpture inspired by centerless grinding—below, three cylinders representing a grinding wheel, regulating wheel and work piece; above, an artistic array of round, ground parts welded together.

The manufacturing floor, however, is all business, straight walls and an expanse of floor holding dozens of grinding machines. Here, operators feed round bar into the machines and the bar comes out the other side, rounder than it went in.

The daily grind

In a way, grinding is like any other machining process. It removes metal. But instead of having one, or two, or a few cutting edges, like a lathe cutting tool, a drill or an end mill, a grinding wheel has thousands of cutting edges; each grain of abrasive acts as a cutting tool.

Centerless grinding, as the name implies, is a process that grinds the surface of a turned part or round bar of material, without the need to support the work piece on centers.

For grinding round bar stock, a “through grinding” process is used. A bar of material, typically twelve feet long, feeds into the grinding machine between a grinding wheel and a regulating wheel. A carbide-tipped strip of steel, the work blade, supports the bar and holds it at the correct height, above the centerline of the grinding and regulating wheels. This is critical to the roundness and diameter tolerances of the bar. Both wheels rotate. The regulating wheel is slanted up a little from the horizontal. As it turns, it pulls the bar past the grinding wheel, so no external feeding mechanism is required.

Each abrasive grain on the surface of the grinding wheel takes a little bite of material every time it passes the bar being ground. This produces a lot of heat, of course, so the grinding area is flooded with a generous flow of coolant. The regulating wheel does not remove any material. It just presses the work piece against the grinding wheel and controls how fast the bar rotates and how fast it moves past the grinding wheel.

A grinding wheel is made from grains of abrasive material bonded together into a cylindrical shape. Different grinding wheels have different sized grains of different abrasives, different bonding agents and different “porosity,” which is the density or spacing of the abrasive grains and bonding material.

The hardness or tensile strength of the material being ground determines which type of grinding wheel to use, explains Steven Tamasi, CEO of Boston Centerless. The company uses primarily silicon carbide and aluminum oxide abrasives. The grinding wheels used on many of the company’s centerless grinding machines are 24 inches in diameter when new, and eight inches wide. The regulating wheels are the same width and 16 inches in diameter. Other machines use different-sized wheels.

The operator first selects the right abrasive grinding wheel for the job, then installs the correct work blade. The work blade must hold the bar at the right height above the centerline of the wheels. The operator adjusts the inclination of the regulating wheel and shapes it to provide a full line of contact with the part. As the grinding wheel is used, it wears down and loses some abrasive grains from its surface. The operator must keep it dressed, or trued, in the correct shape and surface condition for optimum grinding.

Nearly perfect

To produce straightened, ground bar, the first step is straightening. Small diameter bar is run through an automatic straightening machine, which passes the bar between two rollers. This may not straighten the bar completely, so after the operator measures the bar, he sometimes needs to straighten it further using a manual arbor press. Larger diameter bar that does not fit through the automatic straightener is straightened by hand. The operator uses a dial indicator to find where the bar is curved or bent and then applies pressure with a hydraulic ram to bring it in line.

Straightness is measured in deviation over a certain length. A typical straightness tolerance for straightened, ground stock might be 0.005” per foot. The straightened bar then goes through a series of passes on the centerless grinders. Several passes may be needed. If stock is removed too aggressively, the bar can go out of round.

A bar can lose its straightness after grinding, due to stresses being relieved, so straightness needs to be checked while the bar is being processed. Boston Centerless has two specially designed, mobile 12-foot-long straightness gages that operators can wheel to their location to measure bar coming off their machines.

Round and rounder

One’s first impression can be that nothing happens here; round bar stock comes into receiving, and round bar stock goes out from shipping. Customers know the difference, though, and are willing to pay extra for these straighter, rounder, precise-diameter bars. Straightened, ground bar can cost considerably more than the same material straight from the mill. Can it save money in the manufacturing process? Yes, says Tamasi.

Most Boston Centerless customers use the straightened, ground stock in Swiss-type screw machines, he says. A straighter bar can prevent vibration and allow the machine to be run faster. A precise-diameter, very round bar can eliminate chatter and tool breakage, allow tighter machining tolerances and prevent bushings from seizing.

Tamasi points out that typically the cost of the raw material is only about 10 percent of the cost of a screw machine part, so in many cases the benefits of using ground bar may easily outweigh the additional cost.

And some shops find it cost effective buy bar stock ground to the diameter they need for their finished parts.

Ground diameter as final O.D.

Brookfield Engineering Laboratories, a manufacturer of viscosity measurement instruments in Middleboro, MA, has bought ground bar stock for many, many years, according to machine shop manager John Romanuck. The shop uses several different diameters of ground stock, from 1/16” to 3/4”, in stainless steel and brass. It also uses regular mill-run stock.

For parts that are visible to the customer or have special tolerance requirements, the company orders the bar stock ground to size and uses the ground surface for the outside diameter of the finished part.

One application is an instrument stand. Brookfield uses stainless steel special ground to a diameter of 0.623”, the final size of the part. “This is advantageous because we have a ground finish [that looks good],” Romanuck says. “It’s less expensive than if we went for a larger diameter and turned it down and then had it ground].”

Brookfield sells spindle assemblies that consist of a shaft press-fit into a disk. It would be quite difficult to turn the 4-or-5-inch shafts to 1/8” diameter at the tight tolerances required. So it makes sense to start with the stock ground to size, Romanuck says.

His company buys a lot of bar in 1/8” to 5/32” diameter, plus or minus half a thousandth, Romanuck says. “This eliminates all O.D. work.” With only some lathe operations, such as turning the ends or cutting grooves, the parts are finished.

Brookfield also uses straightened, ground stock for close-tolerance work on Swiss-type screw machines. With mill-run stock, the diameter varies too much and “we wouldn’t be able to hold the tolerances we need,” Romanuck says. “The overall quality of the ground stock is a thousand percent better than anything you could get from the mill.”

Through the mill

Mill run bars might hold tolerances of two or three thousandths on the diameter, and half that on roundness. Boston Centerless routinely holds tolerances of two ten-thousandths of an inch (0.0002”) on bar diameter and 50 millionths (0.000050”) on roundness.

With such tolerances, the bars come out with a smooth, fine surface finish; the tighter the tolerance, the smoother the bar’s surface will be. If needed, Boston Centerless can produce an even smoother surface finish, as fine as 8 micro inches, on the ground bar.

A grinding house can work with customers to help them determine what tolerances they need on straightness, diameter and roundness for their particular parts and processes. The grinding company can also work with the mills to obtain the material needed, including any special requirements. Also, a grinding company that buys metal in quantity can provide stock to customers who might need an amount of material that is less than a mill’s minimum order.

Sometimes the mill will refer a customer to a grinding house. “If there is a product that Carpenter is not suited to produce directly,” a referral to Boston Centerless may be in order, says Michael Speers, market manager for medical products at Carpenter Technology Corporation, Reading, PA, a supplier of specialty alloys, including stainless steel and titanium.

Round bar is not all the same. Straightened, ground bar held to close diameter and roundness tolerances is available in many different materials and it can help Swiss-type screw machines produce tight tolerances at maximum speeds, while protecting the machine and the tools from damage.

At Boston Centerless, after the final grinding pass, which produces the desired diameter, the bars are packed for shipment. Since the straightness and surface of the ground bar are critical, protective packaging is necessary to protect the bar from damage. Boston Centerless uses custom-made wooden boxes for shipping larger stock, and plastic or thick cardboard tubes for smaller stock. Bars that need additional protection to prevent damage in shipping are placed in individual plastic mesh sleeves. Ground to order stock is ready to roll.

2 Comments

Looking for a high precision centreless grinder for pin manufactring.

Looking for a high precision centreless grinder for pin manufacturing.