Today’s Machining World Archive:March 2008, Vol.4, Issue 03

by Lloyd Graff

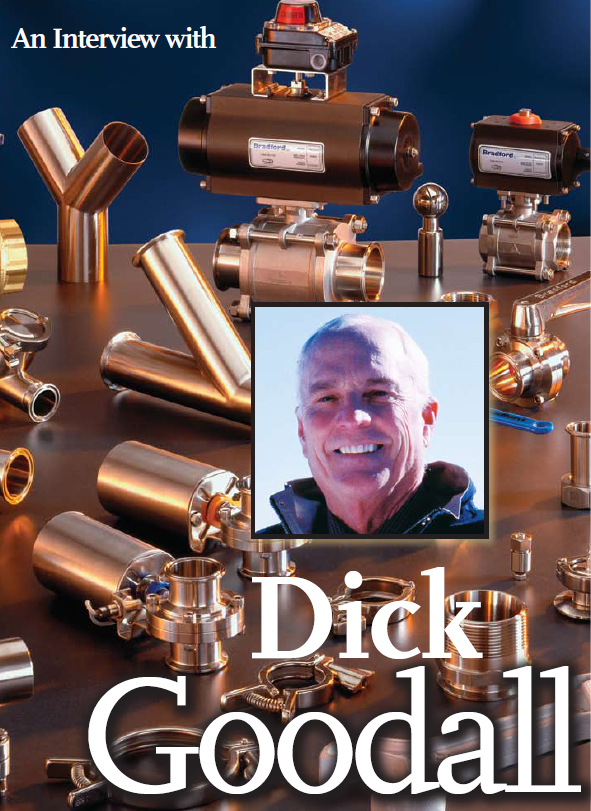

Dixon Valve Fittings Maker

LG: Dick, you sell what some people might see as a mundane and generic product – hose fittings and couplings. How do you see your product?

DG: Couplings are like hinges on a door – somebody always thinks of what the door looks like, but not about the hinges. Every door needs a hinge and every hose needs a coupling. No matter what kind of industry you’re in, you’re going to need a fitting on the end of that hose.

LG: What competitor do you fear the most?

DG: There are a lot of good competitors, good companies that make product. In the quick disconnect stuff, there are the Parkers of the world. But a lot of the stuff that we developed years ago comes from China now.

LG: What is your China strategy?

DG: We opened up a distribution facility in Shanghai. Our number one goal is to be selling into China. We’re selling to these folks and we’re starting to establish distribution in China and India. The infrastructure of those countries is where our country was 60-70 years ago. They’re building roads, dams and buildings, and we have products that they use, and we want to be there selling them product. I think it’s obvious to anybody in our business that a lot of the manufacturing of the product has gone to China. We do some procurement in China of which we notify our customers. But we try to have and maintain the capabilities to make it in United States still. We sell a lot of cam and groove fittings for the petroleum industry and we’re very proud of the designs we have in our manufacturing. We spent a lot of dollars. We have a lot of people manufacturing those products in this country, but some items in that line are made in China.

LG: Describe cam and groove.

DG: It’s the stuff you see on the tanker trucks for loading or off loading. We have a facility in Canada and we make it here in Chestertown, Md.

LG: Do you import product from China?

DG: We do, but not a lot. Let me define something here for you. We have a global market. We have facilities in China; in Europe; we’re selling into Mexico and Canada. We don’t manufacture in Australia anymore – we used to, but that market has totally become a Chinese imported product, not by us but by other folks. Most of our export product that we’re making in the States is going into Australia and Europe. We do have a manufacturing facility in Preston, England, but they’re making more high end stuff for the oil fields like the North Sea.

LG: You’ve acquired a number of smaller fittings players in recent years. What has been your acquisition strategy?

DG: We’ve never gone out and deliberately looked for an acquisition. When opportunities arise in business, we’ve asked: Can this enhance our distributor-base to sell product to their end customers and our end customers? If the answer is yes, then we look at the opportunities: Does this make sense? Does this add to our expertise? If the answer is yes, then we’ll pursue that acquisition. One example was Bradford and Bradford. They make sanitary fittings for food and wine. The fellow came and said, “I’ve owned this company for 20 years, developed it and I’m not going to be in this business anymore. Would you be interested in buying my company?” We bought that company and brought it under the Dixon label; now it’s called Dixon Sanitary, the Bradford line of fittings. His daughter is our general manager of that business unit.

LG: How do you develop the Dixon Valve brand?

DG: Our name is a misnomer. We haven’t made valves for 30 years. It’s fittings. All the big guys in the world that make the valves have that market pretty well wrapped up, and we represent some of those lines in our product mix. We pride ourselves on service. We have a quality product; we will not ever sacrifice the quality of what we make for any reason. The difference is that we’re shipping 99.4 percent of the product out within 12 hours of the order being received, including items we stock from other manufacturers like filters, regulators, lubricators or gauges. We can fill our distributors’ needs quicker than they can going to the source supplier because we service the hell out of these guys. That’s probably the secret of our business.

LG: That goes to the heart of the brand building.

DG: Absolutely. The brand has been around since 1916. I’m not trying to be an infomercial, but we spend a lot of time making sure we satisfy our customers on delivery and service. It’s really important because our guys then don’t have to stock stuff themselves.

LG: Does this strain you to hold inventory in stock?

DG: If you talk to the bankers, that’s what they don’t like. We have a lot of inventory, but we do that deliberately. You can’t service out of an empty bucket.

LG: Do you think lean is a myth?

DG: Lean is not a myth. We’re working on lean shop floor stuff all the time; on value stream mapping; in our distribution; our accounting, our sales, marketing, everything. Lean is not a myth. It’s continuously trying to get better at everything you do and measuring that. Once you measure, you change. We’re measuring an awful lot, not just in production metrics but throughout our

business; otherwise, we couldn’t still be here competing. I think it’s where a lot of manufacturing guys have given up. They say, “Well it’s just as easy to get it made overseas.” We really believe that there’s a lot of future left for manufacturing in this country.

LG: Why do you believe that?

DG: Because we’ve got a lot of smart people here, not just in our company but in our country, and you treat your people the way they should be treated and encourage them to work as teams and things seem to happen right. We’ve been blessed over the years with some absolutely terrific people.

LG: Then why do you think so many people have given up on manufacturing domestically?

DG: Because it’s really easy to meet up with some importer or rep from some China organization who’ll say, “Oh, we’ll make that for you. You’re paying $15 where I can make it for $6.” You say, “Well, your quality is not quite as good, but it’s good enough and I could be more competitive,” so people just give up. It’s the easy way out.

LG: I’ve been in your plants and I see a lot of multispindle National Acme and New Britain screw machines. You’re committed to keeping a robust but highly varied inventory. Where do the old cam operated screw machines fit into an operation like yours?

DG: It’s interesting you mentioned lean. Where we might’ve run 10,000 to 40,000 of a hose coupling and run it three, four times a year, you might be running items now seven, eight, 10 times a year, the same product, running smaller quantities. The screw machine is a little more difficult to get those economic values on how many you run at a time, but we’ve been able to service ourselves

and continue to use that kind of equipment, and filter it into our lean philosophy of running things more often.

LG: You must be successful in doing it because you’re competing against a lot of imported goods and a lot of highly skilled people who are very good at what they do.

DG: Absolutely. Most of the competition that’s left the United States is pretty good, which is good. I think we all like having good competition. It makes life more interesting. What worries you as an individual and a citizen of the U.S. is that some of the key products we need in both our military and our industrial complexes are being made in China now, and that’s scary.

LG: Where do you see growth in your business?

DG: We’re in a lot of different markets. Hopefully when one market is facing tough times, another market picks up. Growth may come with some of the federal programs and road building and dams; we’re into that. We think some of these things are going to be going on for years and we’re going to work hard to be the best supplier that our distributors can get, and try to build that brand. That’s why we started Boss magazine, trying to build the brand not only through distributors but continue to try to pull it through to the end users through the distribution channel.

LG: Do you have much family in the business?

DG: The families originally formed by my grandfather and my brother and I are here at the company. We have people who aren’t family but been around forever. Our president of our company, Lou Farina, has been with the company longer than I have, and his dad’s been with the company 56 years. It might not be blood family, but it’s family. They’ve been with the organization and we feel a lot of responsibility to those folks to maintain and work hard. We try to empower them with a lot of the responsibilities in the organization.

LG: Why have you chosen to stay private?

DG: It’s nice being able to do things without going through layers of bureaucracy. If our folks need a new machine, we get the new machine. With acquisitions, if an opportunity arises, we do things rather quickly, and you can’t do that all the time in public companies.

LG: How about export? Is this a thriving area now with the “weak” American dollar?

DG: It’s exciting. We always sold into Mexico through distribution channels. About five years ago we put our own warehousing facilities in Mexico. We’ve been doing great and now we’re going into Central and South America. We’re selling and sending our first lot of product into our warehouse in India. We have a guy in Russia.

LG: How much does the weak dollar have to do with this?

DG: I don’t think it has a lot because we were doing this before the dollar got weak. It does make it easier, but it’s more or less getting in front of the customer, enhancing the brand, identifying the brand. Most people globally know our brand. We’re a little company but our brand is bigger than we are. Once we made our model the way we wanted to by stocking and delivering to our customer, we’ve been getting business.

LG: Is your business price-driven or brand-driven?

DG: It’s not price-driven. I think brand-driven is part of it. I think we’re service-driven and brand-driven. You can’t be off price much. You can’t be the lowest priced guy and the best quality and best delivery guy. You can’t fit all those things into one bucket. We are very price competitive and we do lead in some price areas, but we don’t ever give up that to sacrifice quality or service.

LG: How important is it for you to develop team spirit?

DG: The culture of the organization has to do with the people who are in the organization. We spend a lot of time talking to people, whether they’re the people running a machine downstairs, sweeping the floor or one of our vice presidents of accounting. We have meetings with every one of our employees. We meet in groups of 10 to 20 people four times a year, and we talk about how the business is going. We economically share with our people when we meet our growth above and beyond our compensation programs. We realize our people are the key to our longevity and success. We believe in it, and it’s manifested in people staying a long time. The continuity

of effort means people know our business; we know how we want to conduct business and conduct it that way.

LG: I think cumulative memory is one of the most misunderstood and least valued items in today’s business world. When a company has people who’ve worked in the company for a long time, they have company memory. That is extremely valuable.

DG: You’re right. When your employees start feeling part of the company rather than just an employee or a worker and they feel they have some value, if they feel they can help make changes, it reinforces the culture of working together. About 25 years ago, we started asking how to get more people involved in our decision-making processes. We realized we were having a lot of fun, but how many other people were having it?

LG: What do you do besides business?

DG: I love working out, did triathlons until I messed up my Achilles. In the summertime, I love boating.

LG: Do you abide by the argument that there isn’t a shortage of jobs; there’s a shortage of skills?

DG: I’m not sure I agree with either. There might be a shortage of skills but those skills can be taught.

LG: You’ve been in business for 92 years. You’ve defied the odds of having a family business survive at least three generations. You’ve defied the odds as far as having a machining business thriving in the U.S.

DG: We continue to buy equipment. We think that’s important. Did you read Jim Collins’ book Good to Great?

LG: I did.

DG: There’s one thing in there that I read and read it again and didn’t get. I had an opportunity to be at a meeting where Collins was and I asked him about it. He said it is about the “who,” not the “what.” Without the “who” you’re never going to be successful. That may sound a little crazy if you haven’t read that book. But if you have the right folks doing whatever job they’re doing, you’re going to be successful. I believe that it’s good people who make it all possible.

LG: It’s the job of management and owners to find the good people; it’s also their job to give good people interesting problems to work on and then reward them in satisfying ways.

DG: You get the right people, you treat them right, and they’ll treat you and the business right.

2 Comments

Pro Flow Dynamics, LLC is a supplier of leading fluid handling components, offering fluid handling and measurement solutions to our customers. We are based in Corona CA and are part of the Flowmax group of companies.

cam and groove, cam and groove coupling, cam and groove couplings

That’s great article!! thanks for the information.