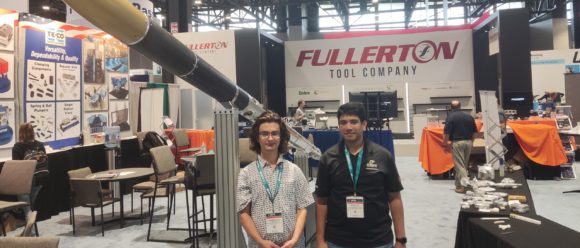

At IMTS 2022, I stumbled upon a booth with an impressive 28 foot rocket on display, constructed by students from the Purdue University Bechtel Innovation Design Center.

Anirudh Pal, an operations manager at Bechtel, and Xander Wells, an undergraduate teaching assistant at Bechtel, told me the story behind the rocket’s creation when I interviewed them for today’s podcast.

The Bechtel Innovation Design Center is a makerspace, where undergrad students of all different majors have the opportunity to work together on creative manufacturing projects, incorporating a wide variety of manufacturing processes. Participating in the makerspace is completely voluntary, and students at the design center learn production skills primarily from each other.

Facebook: https://lnkd.in/dB_nzFzt

Instagram: https://lnkd.in/dcxjzVyw

Twitter: https://lnkd.in/dDyT-c9h

Main Points

Background of Anirudh Pal and Xander Wells

Anirudh Pal lived in Dubai from fifth grade through high school before attending Purdue, majoring in computer science. He says that one of the main reasons he chose to go to Purdue was Bechtel. After undergrad and further education, he came back to work at Bechtel as a faculty member.

Xander Wells grew up in Chicago and also lived in China for five years before attending Purdue. He is a sophomore, majoring in aerospace engineering, but actually making physical stuff is his passion.

Overview of Bechtel Innovation Design Center

Students of all majors at Purdue have access to Bechtel. They primarily learn manufacturing processes and machine maintenance from each other.

In the interview, Xander told the story of an English major who participated at the Bechtel Center, who after getting her masters degree, went on to work as a manufacturing engineer.

Students use the makerspace to work on projects for classes, participate in design competitions, create prototypes for entrepreneurial pursuits, or just make stuff for their own enjoyment.

At Bechtel, students have the resources to do 3D printing, metal working, waterjet cutting, wood working, laser cutting, CAD/CAM, electronics, assembly and prototyping, and work with fabrics.

Bechtel brings in industry experts to further expand the students’ knowledge of manufacturing, such as representatives from Kennametal, one of the Center’s sponsors, who come in several times a semester to train students to use their tooling.

Rocket on Display at the Booth

I met Xander and Andirudh when I noticed a rocket on display that was built at the Bechtel makerspace. The rocket is around 6.5 inches in diameter and 28 feet tall. It weighs 90 lb when dry, 130 lb with fuel. It uses liquid methane and liquid oxygen as propellents, which Xander told me is the same fuel that SpaceX uses for its rockets. It produces around 900 lb of burn force for over 10 seconds continuously. For two and a half years, Xander and fellow students from the Purdue Space Program club (PSP), mostly engineers of a variety of specializations, designed the rocket, and produced and assembled its components.

The rocket was launched in the Mojave desert twice in a period of 24 hours. Xander said this may be a record for turnaround time for a liquid methane rocket built by college students, and it would be an impressive turnaround time for any rocket relaunch.

Perspective on Skills Shortage

I asked Xander and Anirudh to give their take on the skills shortage that the manufacturing world continuously laments.

They told me they hope that Bechtel can play a role in creating manufacturing experts who can pass on their knowledge to other aspiring manufacturers. They said that YouTube is having a positive impact on attracting a younger population to manufacturing. They rattled off ton of channels about manufacturing and designing created by passionate and entertaining YouTubers.

Anirudh, said he has observed in some manufacturing shops that the most experienced people can be stuck doing things the way they’ve always been done. He said he hopes new young people coming into the workforce will introduce new open-mindedness to improve the way companies approach processes.

Question: If you had access to a deluxe makerspace and abundant spare time, what would you build?

Podcast: Play in new window | Download

4 Comments

It would be nice to manufacture some beautiful custom guns…

So much fun, so little time. 😀

Oy! 😆

This is what the local UCF University engineering dept. and others are doing to produce inexpensive prosthetic devices for children and young adults. The links are a few years old, but when I heard about this and the ability to cut costs to a bare minimum, I thought this was a fantastic project.

https://www.youtube.com/watch?v=43sFzm_a4cQ&ab_channel=BillGates

https://www.youtube.com/watch?v=2c1Iphcp7wM&ab_channel=KSAT12

https://www.youtube.com/watch?v=pT5zc2CFLdE&t=1s&ab_channel=LinkW.

It would be fun to build a capsule to fly uncle joe to mars.