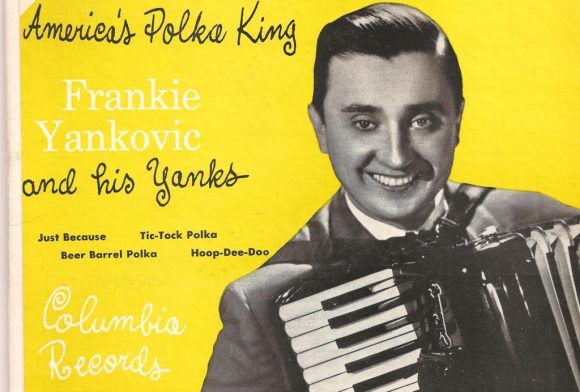

Is the National Acme screw machine today the accordion of machining?

Are shops staking their future on the Acme the polka bands of manufacturing?

As sad as I am to admit it, I am close to conceding that at least the 6-spindle Acmes have become hard for a used machinery dealer to turn into money.

The reasons are many, and certainly there are exceptions to this observation.

1) You can’t find operators to replace the thousands of retiring setup people and tenders of the cam operated screw machines. An Acme makes money if you can keep it running. In today’s machining world of lean purchasing, the 100,000 piece orders are increasingly rare. No setup folks means idle machines when orders are usually 10,000 pieces or less.

2) An Acme is cam operated in a constantly changing world. To be prepared to run a variety of jobs you need to store cams and have a record of them. Shops today have a finite amount of usable space. Owners do not want to keep track of bulky cams that are expensive to make.

3) Repairs can be troublesome. Most firms do not have the expertise to repair broken or sloppy machines. Repair parts are expensive when you can find them. Sellers of spare parts are dwindling and not carrying everything. Attachments usually are not immediately available, so Acme users need to keep old machines around to rob for spare parts.

4) If you want to keep a 40 to 70-year-old Acme running, who can give it a heart transplant? The sad fact is that even with thousands of viable Acme 6-spindles still running and making money, there are just a couple of Acme rebuilders still around to bring them back to life.

5) But what about the 8-spindle Acmes? It appears that the 8-spindle National Acme, especially the 3/4″ RA-8, 1-1/4″ RB-8, and 1-5/8″ RBN-8, still have a place. Judging by the demand that Graff-Pinkert sees, those machines, especially with Logan threading and pickoff attachments, fill the niche of efficient long-run production at an affordable price. Compared with European competition like Schütte, Gildemeister, Tornos, or ZPS, they sell for a pittance, so shops accept their deficiencies and run them until they drop.

For my whole life, selling the stallion of cam screw machines has put food on the table. These are the machines that help win wars and pour out fittings for faucets around the world. But even Secretariat limps around the barnyard eventually.

From my standpoint of a machinery dealer, the 6-spindle Acme-Gridley is now a bargain item. I write this with genuine sadness because a 1-1/4″ RA-6 with a good stem was gold just a few years ago. Today, many people still like them, but for a non-rebuilt machine Graff-Pinkert generally asks between $10,000 to $40,000.

The question is, will they become accordions that most people no longer know how to play?

Or, will 6-spindle Acmes make a comeback with an expanding Mexican market, like we have seen with Davenports in the last three years. It could happen.

Please come back Frankie Yankovic!

Questions:

What is the oldest machine in your shop, and is it still making money for you?

Do you still love a good polka?

11 Comments

sn 40482 and 40914 are 1-5/8″RA-6 Acmes, inferior to RB’s but still running with ball spindle bearings and single-roll feed mechanisms. I think those are WW2 machines. Almost everything we make is for our own use in assemblies we sell, so we design setups for quick changes of 1-8 hrs across families of parts. Our batch sizes are often defined by heat treating or plating minimums instead of our own setup efficiency. We have apprentices learning from our experience. We rebuilt a 1979 2-5/8RB-8SS in 2020 with new hydraulics and new controls, involving 4 different contractors plus the rigger. NE Indiana is a good place to be.

Ben, you have a good thing going. As Frankie Yankovic would say. Hoop Dee Doo.

“In heaven there is no beer, that’s why we drink it here,

And when I’m no longer here, my friends will be drinking all my beer !”

Daniel,

Are those lyrics from the Beer Barrel Polka they play at Milwaukee Brewers and Bucks games?

Are you talking about “Roll out the Barrel?”

I think so. I’m pretty sure they play it at the Wisconsin football games, but I used to hear it in my old Polish neighborhood in Detroit.

I took accordion lessons in my youth. I thought it was such a cool instrument. It was a short experiment but I have slways loved the music. Do we have any accordion players reading this blog. Ehat is your favorite song?

The difference between an accordion and an onion ?

NOBODY cries when you cut an accordion in half.

My wife loves Polkas!

Me – not so much.

Guess I spent too much time at German Beer Fests.

I love the 80s music and classic rock.

Like Bob Seger said:

I like that old time rock ‘n’ roll

Don’t try to take me to a disco

You’ll never even get me out on the floor

In ten minutes I’ll be late for the door

I like that old time rock ‘n’ roll

Still like that old time rock ‘n’ roll…

We are not a screw machine house.

We are a manufacturer.

I let someone else figure out my screw machine parts.

We have several CNC mills

And several punch presses.

A couple Hardinge manual turret lathes

But we have some classics:

A few Kearney Trecker Milwaukee horizontal mills – true workhorses!!! circa early 1940s

Still going strong!

And my go to:

A south Bend 10L toolroom lathe, still with a flat leather belt, also circa early 1940s

Keep up the good fight…

Rick,

I still love Pete Seeger.

Irene Good Night has put two generations of children to sleep. And their father,too.y

I find my polka listening habits trend towards another Yankovic. The weird one.

Antiques can still make decent parts. We have a big old monster of a lathe here, which I’ve only seen another example of…in pictures of a railway museum in Sweden! Thing still makes parts for us, and them!

Last week I ground the shims for aligning the rotary axis back into spec on our 5 month old GROB 5 axis machine after a little learning experience banged out. I used our Grand Rapids surface grinder that left the factory on June 22 1959 almost exactly 6 months before I was born. Had to chuckle a little bit as the oldest guy running the oldest machine in the shop to fix the newest machine. I still like the quality built old stuff but we make all the big money with the new stuff.